Textile Raw Materials Processing Machinery A

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 2 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery of Textile Raw Materials Processing Machinery A

| Packaging Detail: | to be packed in seaworthy strong wooden case or carton. |

| Delivery Detail: | about 20days after receipt of the down payment. |

Specifications of Textile Raw Materials Processing Machinery A

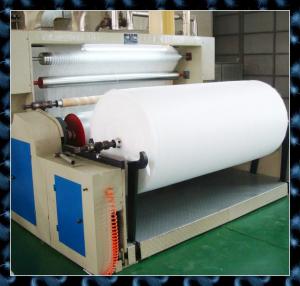

It is used for making hollow cotton fiber PP into the fluffy cotton products.Textile Raw Materials Processing Machinery.

output: 100~350kg/h

Power:

Total power; 2.95KW voltage: 380V, 50Hz

Main power : 2.2kWthe power of the conveying fan: 0.75kW

overall size :( L*W*H): 3000×850×1300mm

gross weight: 600kg

Application of Textile Raw Materials Processing Machinery A

It is mainly used for making hollow cotton fiber PP into the fluffy cotton products look like clouds

And applicable to garment, bedding, pillow, and stuff toy, Make products more plumpy & elastic.

It wears conveying fan (user can choose the outlet, it can be padded directly).

- Q:How to determine the rear beam position of the rapier loom?

- Weaving fine yarn high-density fabric when the beam forward, warp tension increases, is conducive to open the shed, reducing the warp beam on the back beam of the enclosing angle, reduce friction, reduce the warp break.

- Q:What is antifelting?

- And remove the basis for the formation of felt. Felt resistant finishing fabric can reach the required level, known as super wash cloth

- Q:What is wrinklng?

- The main fabric of crease finishing is cotton cloth, polyester / cotton blended fabric and polyester filament fabric.

- Q:What is easy to soil (soil - releasing)?

- Easy to defrosting is to make the fabric surface dirt easy to use the general washing method to remove

- Q:What are the rapier looms?

- E) LED panel visual display of the whole operation of the loom, and positioning sensor signal input

- Q:What is coating?

- Coating on behalf of the fabric with anti-down, waterproof breathable, shading insulation, fire-retardant, conductive and imitation leather and other fabrics.

- Q:What is the difference between air-jet looms and water-jet looms for weft storage?

- Spray the different carrier, water is water, jet is used high pressure gas.

- Q:What is the principle of textile machine?

- The use of shuttleless looms is important for increasing the variety of fabrics, adjusting the fabric structure, reducing fabric defects, improving fabric quality, reducing noise and improving working conditions.

- Q:what is pressing technology?

- The former through the extrusion and friction will be ironing the fabric flat, and given the luster. Fabric elongation is small, high productivity, but the effect is not lasting

- Q:How to open a good air jet loom?

- 3. Semi-term maintenance and processing need to check the winding and whether the clean, the main drum, drum on the drum marks and scars, whether the inside of the yarn pin is dirty, whether the opening wire rope elongation or damage, back spring There is damage, open wire rope connecting seat bearing wear. Whether the belt tension is appropriate, whether there is damage, the sensor is working properly

1. Manufacturer Overview |

|

|---|---|

| Location | Chuji, China |

| Year Established | 2008 |

| Annual Output Value | 100Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 80% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 12000 square meters |

| No. of Production Lines | Above5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Textile Raw Materials Processing Machinery A

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 2 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords