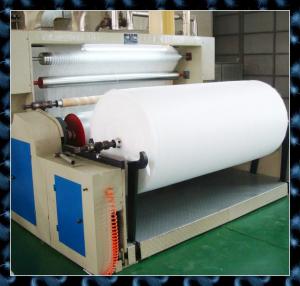

Single Yarn Warping Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 100 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Single Yarn Warping Machine

1.Warping width: 60cm

2.Warping speed: 0-240m/min)

3.Warping length:1.8-18m

Packaging & Delivery of Single Yarn Warping Machine

Packaging Details: standard seaworth transportation packing

Delivery Detail: 60 days

Technical Parameters of Single Yarn Warping Machine

1. Warping width: 60cm

2. Warping speed: 0-240m/min(speed control by frequency conversion)

3. Warping length:1.8-18m

4. kinds of yarn: wool, cotton, synthetic, silk and other kinds of yarn

5. Warp density:min.4ends/cm---max.250ends/cm

6. Automatic leasing device

7. Textile design software and computer

8. Stand creel

- Q:What is an edge cloth?

- Woven fabrics are loom in the form of shuttle, the yarn through the by, zonal staggered and its organization is generally plain, twill and satin three categories and their changes in the organization (modern also because of non-woven Machine applications, such fabric weaving without the form of shuttle, but the fabric is still woven class)

- Q:Where is PET resin generally used ?

- 3. Electrical and electronic: manufacturing connectors, coil bobbin, integrated circuit shell, capacitor shell, transformer shell, TV accessories, tuners, switches, timer shell, automatic fuses, motor brackets and relays.

- Q:What is wrinklng?

- The main methods are: First, the use of mechanical pressure to make the fabric irregular irregular wrinkle appearance, such as hand wrinkling, rope-like wrinkles, stuffing, etc.

- Q:What is the history of textile handmade machines?

- But because of the matching of hand-woven machinery, the advanced areas into the manual machine textile history

- Q:What is the fluff?

- Therefore, the wool fabric after the fluffy hair can get a longer fluff, after the fluff can get wavy long hair

- Q:What are the rapier looms used for processing?

- Corduroy Khaki Woolen Cowboy Canvas These can all be done

- Q:What are the characteristics of the edge weaving?

- Fabric variety variety. As a clothing fabric, good resistance to washing, can be refurbished, dry cleaning and a variety of finishing

- Q:How high is the efficiency of towel rapier looms?

- Rapier weaving speed is relatively slow 150-200RPM, variety adaptability, less investment, cheap accessories.

- Q:How much is the razor loom?

- 5, opening time (comprehensive degree) will also affect the warp and weft yarn shrinkage, when the opening time earlier, the warp yarn shrinkage smaller, weft shrinkage larger

- Q:How to open a good air jet loom?

- The working principle is the use of air as the weft insertion medium, with the jet of compressed air flow on the weft to produce friction traction force to pull the weft with the shed, through the jet jet to achieve the purpose of weft insertion.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangyin, China |

| Year Established | 1999 |

| Annual Output Value | 10-30Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9002 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 10000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Single Yarn Warping Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 100 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords