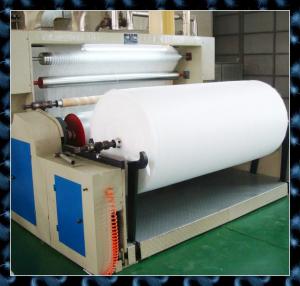

Textile Raw Materials Processing Machinery D

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 2 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery ofTextile Raw Materials Processing Machinery D

Packaging Detail: to be packed in seaworthy strong wooden case or carton.

Delivery Detail: about 20days after receipt of the down payment.

Specifications of Textile Raw Materials Processing Machinery D

It is used for making hollow cotton fiber PP into the fluffy cotton products.Textile Raw Materials Processing Machinery.

Main specification:

output: 100~350kg/h

Power:

Total power; 2.95KW voltage: 380V, 50Hz

Main power : 2.2kWthe power of the conveying fan: 0.75kW

overall size :( L*W*H): 3000×850×1300mm

gross weight: 600kg

Application ofTextile Raw Materials Processing Machinery D

It is mainly used for making hollow cotton fiber PP into the fluffy cotton products look like clouds

And applicable to garment, bedding, pillow, and stuff toy, Make products more plumpy & elastic.

It wears conveying fan (user can choose the outlet, it can be padded directly).

- Q:What is the leading maintenance of the rapier loom?

- Insert 20 retractor fittings (0100-9) in turn and check that the hooks are flexible

- Q:What is the role of the parchment loom?

- Now into the late autumn wind blowing more dry we have to close the doors and windows workshop to sprinkle the control of the workshop moisture regain temperature and humidity as far as possible control in about 70%

- Q:Where is PET resin generally used ?

- 1. film sheet: all kinds of food, medicine, non-toxic sterile packaging materials; textiles, precision instruments, electrical components of high-grade packaging materials; tapes, video, film, computer floppy, metal coating and photographic film And other materials; electrical insulation materials, capacitor film, flexible printed circuit boards and membrane switches and other electronic fields and machinery.

- Q:What is the weft insertion of the rapier loom?

- Rapier loom is divided into rigid rapier and flexible rapier two, as the name implies, rigid rapier rapier is a metal rigid material, flexible rapier rapier can be bent flexible material, due to flexible rapier Institutions are simple, small footprint, and now most of the rapier looms are flexible rapier.

- Q:What is it boiled?

- Cooking finishing is the wool fabric in the tension with hot water treatment, so that the formation and subsequent wet treatment is not easy to deformation process.

- Q:What is weight gain technology?

- The weight gain is a process that uses chemical methods to increase the weight of the silk fabric

- Q:What are the rapier looms used for processing?

- Suitable for weaving plain weave and twill weave fabric is characterized by easy color change

- Q:What is the rigidity technique?

- The process of dipping and drying the fabric to obtain a thick and stiff effect is a finishing method for improving the feel of the fabric.

- Q:What is coating?

- The finished fabric is always felt in terms of texture and performance

- Q:What is the difference between rapier looms and air-jet looms?

- Air-jet loom speed generally made in the 500-650RPM, the fastest imports in the 1200RPM, the yarn demanding (yarn quality, sizing quality), put a lot of air compressor requirements higher

1. Manufacturer Overview |

|

|---|---|

| Location | Chuji, China |

| Year Established | 2008 |

| Annual Output Value | 100Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 80% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 12000 square meters |

| No. of Production Lines | Above5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Textile Raw Materials Processing Machinery D

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 2 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords