Refractory High Alumina Brick for Blast Furnace Ball Mill

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Refractory High Alumina Brick for Blast Furnace Ball Mill

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | Uncertain | Al2O3 Content (%): | ≥60% | MgO Content (%): | Uncertain |

| CaO Content (%): | Uncertain | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | Uncertain |

| SiC Content (%): | Uncertain | Model Number: | LNHAB14001 | Brand Name: | |

| Apparent porosity,%: | 18-22% | Cold Crushing strength Mpa: | 45-80Mpa | Fe2O3 %: | ≤2.0% |

| Sample Request: | Free | Advantage 1: | The most competitive price | Advantage 2: | Abundant Experience |

| Advantage 3: | Different Moulds. Save mould fees for you | Advantage 4: | Large stocks. Guarantee prompt delivery | Advantage 5: | Professional Packing |

| Advantage 6: | Lower ferric Oxide,porosity,density,higher CCS and exact tolerance |

Packaging & Delivery

| Packaging Details: | Packed on wooden pallets with water-proof cover, and tightened with plastic/steel bandages |

| Delivery Detail: | In 20 days after prepay |

Specifications

Resisting high temperature

2.Great bulk density

3.Low iron content

4.Good eroding resistance

5.ISO certificate

Description:

High alumina bricks are produced with selected bauxite chamotte by advanced process and strict quality control. The main mineral components are corundum and mullite phases. It features excellent high temperature mechanics and chemical corrosion resistance.

Features

1.Resisting high temperature

2.Great bulk density

3.Low iron content

4.Good eroding resistance

Applications:

1. Steel furnaces

2. Iron making furnaces

3. Glass kiln

4. Ceramic tunnel kiln

5. Cement kiln

Our competitive Advantage:

1.Competitive Price. Make the products competitive in your market.

2.Abundant Experience. Prevent cracks and twist in bricks.

3.Different Moulds. Save mould fees for you.

4.Lower ferric Oxide,porosity,higher refractoriness,density,higher CCS and exact tolerance.

5.Strict Quality Control. Meet clients’ quality requirement.

6.Safty packing,prompt delivery time,and excellent after-sales services.

7.Large stocks. Guarantee prompt delivery.

8.Professional Packing. Avoid damage and secure the goods in transportation

Specifications:

Ordinary High alumina brick

Item | HA60 | HA70 | HA75 | HA80 |

AL2O3(%) | ≥60 | ≥70 | ≥75 | ≥75-80 |

SIO2(%) | 32 | 22 | 20 | ≥18 |

Fe2O3(%) | ≤1.8 | ≤1.8 | ≤1.8 | ≤1.8 |

Refractoriness °C | 1790 | >1800 | >1825 | ≥1850 |

Bulk density,g/cm3 | 2.4 | 2.45-2.5 | 2.5 | 2.55-2.6 |

Softening temperature under load | ≥1470 | ≥1520 | ≥1530 | ≥1550 |

Apparent porosity,% | 22 | <21 | <21 | <20 |

Cold Crushing strength Mpa | ≥45 | ≥50 | ≥54 | ≥60 |

Phosphate bonded high alumina bricks

Item | L75 | L77 | L85 |

AL2O3 % | ≥75 | ≥77 | ≥80-85 |

Fe2O3 % | ≤3.0 | ≤3.0 | ≤1.8 |

Ca0 % | ≤0.6 | ≤0.6 | ≤0.6 |

Refractoriness °C | ≥1800 | ≥1800 | ≥1850 |

Bulk density g/cm3 | ≥2.65 | ≥2.70 | ≥2.80 |

Cold crushing strength MPa | ≥60 | ≥64 | ≥110 |

Refractoriness under load 0.2MPa °C | ≥1350 | ≥1300 | ≥1350 |

Application | Used for high temperature parts lining of cement rotary kiln | Used for Badly worn parts of cement rotary kiln | |

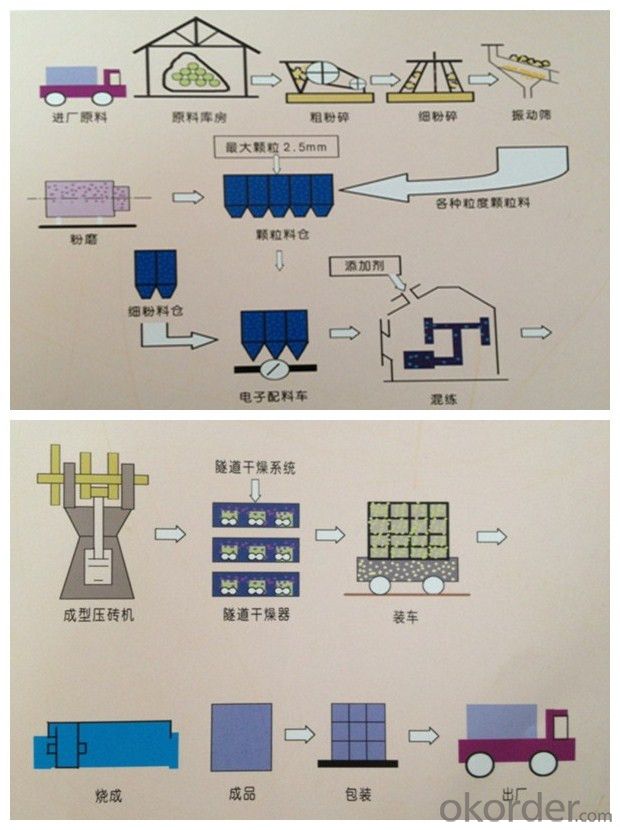

Process flowdiagram:

After the contract is signed, the relevant responsible person tracked production progress, product quality and product packing aperiodically. During the term of contract sent on time with quantity and quality guaranteed.

FAQ

1.Are you a manufacturer or trader?

Factory + trade (mainly factories, at the same time, we operates other related products)

2.Can we visit your factory?

Sure,welcome at any time,seeing is believing

3.What's the MOQ of trial order ?

No limit,We can offer the best suggestions and solutions according to your condition.

4.Which payment terms are you accept?

T/T,LC,Western Union,moneygram,Paypal are available for us.

5.After an order is placed, when to deliver?

15-25days

6.Is your company accept customization?

We have own factory and excellent technical team, and we accept OEM service.

7.How about your company's certification?

SGS,ISO9001 and Test Report,also we could apply other necessary certification.

8.How to solve the quality problems?

If the products are not conform to customer samples or have quality problems, our company will be responsible to make compensation for it.

- Q:How to reduce porosity of high alumina brick

- When proportioning, the ratio of coarse to medium to fine is 4:2:4, and the maximum particle size should be no more than 5mm. The mixing order is as follows: first adding coarse particles, then adding sulfite pulp waste liquid, premixed 3min, then adding high aluminum fine powder for mixing. The operation process is coarse and fine particles added in sulfuric acid with crushed pulp waste.In order to reduce the porosity, our company suggested that the single-sided pressure changed to double-sided pressure instead of double-sided pressure, the number of strikes should also vary according to the amount of feeding. If the kiln is fired, the location of the fire hole shall be adjusted so that the middle part is dense, the edge is thin, and the door near the kiln is properly encrypted so that the temperature difference between the furnace top and bottom and the temperature difference between the inside and outside are not greater than 20 degrees.

- Q:The cloth blowing is not uniform on the lime kiln refractory brick is damaged it

- People with the shaft kiln cement clinker kiln, because of small size, low calcination temperature, using only Al2O3 containing a single clay brick is 30 ~ 40%, the rotary kiln was improved in the early Yuan faith this experience, use of high alumina brick and clay brick, from 60s onwards, due to large scale kiln and to strengthen the operation of the high temperature parts of kiln lining, alkaline brick masonry is widely used, the main varieties are: magnesia chrome brick, magnesia spinel brick and dolomite brick.

- Q:What is fireproof concrete?

- According to the different properties of fire resisting and heat resisting concrete, they can be divided into silicate, aluminate, phosphate, sulfate, chloride, sol and organic substance, fireproof and heat-resisting concrete, etc.. The following are mainly used silicate, aluminate, phosphate, sulfate fire, heat-resistant concrete.

- Q:What kind of material is the general metal case?

- Generally speaking, the outer surface of the case is usually made of a steel plate of more than 1 millimeters. The thickness and the material of the steel plate are directly related to the rigidity of the case, as well as the capability of sound insulation and anti electromagnetic radiation. The regular manufacturers of the chassis plate thickness not less than 1.3mm, but there are also some small manufacturers with a thickness of only about 1mm steel, we do not need the ruler to the amount, as long as you put him up, the more weight in the same volume of the chassis is better, in addition, we can also use the finger bomb case shell. If you can hear the crisp percussion sound proof of the casing plate is thin and brittle, if you hear is relatively dull and heavy sound that the chassis material must be good, good general steel plate coated with a layer of thin zinc (bright part), so it can withstand high strength, impact resistance, hardness high elasticity. The frame parts of the chassis are made of high quality materials with high hardness. They are bent into angle shapes or strip shapes. We can shake the chassis frame of the case by hand. Good chassis should be relatively stable, and inferior chassis light is easy to shake. When choosing, we should also pay attention to the outer edge of the case and the edge of the inner bracket. Whether the incision is smooth or not, a good case will not appear in the case of rough edges, sharp edges, burrs and so on. While the poor case appears above phenomenon, often appear when installing the blood splattered". Generally speaking, the chassis must go through the corresponding grinding process before leaving the factory. The edge of the flat plate some burr, edges and corners are rounded, the corresponding fold some corner. When you install such a case, you don't worry about cuts, and some rough, poorly built cabinets tend to scratch your hands.

- Q:The difference between clay bricks and clay bricks

- Sintering bricks do not have clay bricks, so sintering bricks are made of stone. Clay brick is clay cooking, two yo, qualitative difference, but the appearance and color almost, but the quality is very different, life expectancy is also a great gap.

- Q:What are the reasons for the spalling of refractory bricks in the production of lime kiln?

- Therefore, the choice and masonry of refractory bricks are of vital importance. If there is a brick kiln kiln off block process of reproduction, is now because of the use of refractory brick kiln material mostly three grade high alumina bricks. The content of AL2O3 is about 55%, of which the content of Fe2O3 is about 2%, which is weak, and the alkali corrosion resistance is a little worse. In a containing three grade high alumina bricks in the composition of AL2O3, Si2O3, and other elements also contain K, Na trace, were the most, thus causing the system of the low melting point is very low, even at 1400 DEG C has been liquid phase, and generate CaAL12O19 limestone and calcium feldspar etc.. Form corrosion loss. Therefore, a long time will cause the loss of block. On the one hand, it may be caused by construction.

- Q:The difference between aluminium refractory and magnesia refractory

- Magnesia refractory belongs to alkaline refractory materials refers to refractory products such as magnesia magnesia brick magnesium iron spinel magnesium aluminum spinel magnesia ramming materials and other products of raw materials is the main crystal phase is periclase magnesia products

- Q:Introduction of high alumina brick

- Three alumina silicate refractory product with a content of two Al2O3 (48%).

- Q:What causes breakage of refractory bricks?

- Refractory brick is a non metal mineral products can be used in the high temperature of 1550 DEG C under belongs to a class of inorganic, used in high-temperature furnace lining materials as protection kiln, which causes damage, usually have these points.Furnace temperature is not clear, there is no corresponding choice of refractory bricks.Physical impact, abrasion and erosion cause damageChemical factors, especially chemical industry, should be made of refractory bricks, which should be resistant to penetration and erosionIV: products from the factory when the factory did not pass the quality inspection standards

- Q:What are the high temperature refractory mortars made of?

- Products used in metallurgy, building materials, machinery, chemical, power industry, industrial thermal furnace, for masonryBuilding clay brick, high alumina brick and corundum brick have the characteristics of full grey seam, good airtightness, high bonding strength, high temperature performance and suitable construction time

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory High Alumina Brick for Blast Furnace Ball Mill

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords