Prepainted Rolled Steel Coil for Roofing Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic description Info.

Surface Treatment:Coated

Technique:Cold Rolled

Standard:JIS

Color:All Ral Color Are Available

Zinc Coating:30-120G/M2

Width:914-1250mm

Thickness:0.18-0.6mm

Export Markets:Global

Additional Info.

Trademark:VST

Packing:Standard Export Package

Origin:China

Production Capacity:10000t/Month

Main Feature:

1, Pre-painted Steel Coil Can be used in building material field, galvanized wire steel tape and mainly other fields.

2, All color can be customized

3, Good quality with competitive price

Secifications

Performance testing of color coated steel coil | ||

Item | Method | Consequence |

Tensile Test | Tic-Tac-9mm 5mm cross cupping | No damage |

Bending Test | T≤ 3 | No damage |

Boiling Test | 100° Cboiling 1 hour | No damage |

Water Resistance | 1000hours immersion in 40° C(edge) | No damage |

Moisture Resistance | 50° C90%100hours(edge) | No damage |

Fire Resistance | Samples were placed in incubators, remove greenhouse cooling, and then test the adhesion | Long-term Environment in 100° C |

Fire Extinction | Liquefied petroleum gas or natural gas burner | Immediately turn off |

Drug Resistance | 10%hydrochloric acid, saturated calcium, 10%H2SO4, 10%NAOH, gasoline, ethanol | No color and trace change |

Salt spray test | 5%Nacl, 35± 2° C, 500hours | No damage |

Coating performance test standard | ||

Test item | Positive standard | Back standard |

Dry film thickness(um) | 14-16 | 7-9 |

Glass(60degree) | High 70± 5, medium40± 5, low30± 5 | 30± 5degree |

T bending | 3 | 3 |

Impact strength | 6.3 | 5.8 |

Pencil hardness(H) | H | H |

MEK(Per) | > 100 | > 100 |

Cross cut | 0 class | 0 class |

Acid resistance | 50%H2SO4 immersion in300hrs, no color, wrinkling, fading, change | |

Alkali resistance | 50%H2SO4 immersion in300hrs, no color, wrinkling, fading, change | |

Aging-resistance | 1 st class loss of color and glass | |

Salt spray | 500 | |

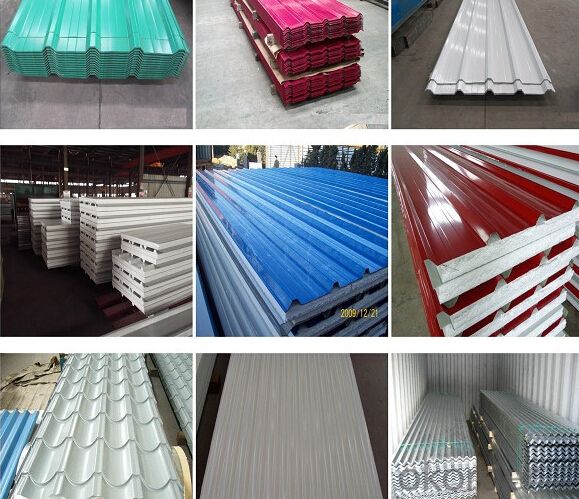

Images

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q:How do steel coils contribute to the construction equipment industry?

- Steel coils are essential in the construction equipment industry as they are used to manufacture various components like beams, plates, and tubes. These coils provide the necessary strength and durability needed for constructing heavy machinery and equipment. Additionally, steel coils are also utilized in the fabrication of structural frameworks, reinforcing bars, and other critical parts, ensuring the integrity and safety of construction equipment.

- Q:How do steel coils contribute to the marine equipment industry?

- Steel coils contribute to the marine equipment industry by being a crucial component in the manufacturing of various marine equipment such as ships, boats, and offshore structures. These coils are used in the construction of hulls, decks, and other structural parts, providing strength, durability, and corrosion resistance. Additionally, steel coils are used in the production of marine equipment components like pipelines, storage tanks, and marine engines, ensuring their reliability and performance in harsh marine environments.

- Q:When I took guitar lessons, I found that the Nylon strings are easier for me, but I love the sound of steel strings. Now, I have my own acoustic guitar, and 2 strings broke off, so I'm getting strings today. I'm not sure if Nylon strings would 'fit' on my guitar, and it's to soft of a noise. But the steel are much better sounding, but it's a little bit harder to push the string down on the fret. Which do you prefer, why?(:

- You cannot put nylon strings on a steel-stringed guitar. If you find that the steel strings are too hard, get a lighter gauge which will ease up the tension. This way you can build up finger strength gradually as well as build up the callouses on your finger. You can always get a thicker gauge string later on if you want a deeper sound.

- Q:What are the different types of steel coil surface protection methods?

- There are several types of steel coil surface protection methods, including oiling, painting, galvanizing, and polymer coating. Oiling involves applying a thin layer of oil to prevent corrosion and rust. Painting involves using a protective paint coating to provide a barrier against moisture and other corrosive elements. Galvanizing involves coating the steel coil with a layer of zinc to provide corrosion resistance. Polymer coating involves applying a protective polymer film to prevent corrosion and improve durability.

- Q:Can steel coils be used in the production of furniture?

- Yes, steel coils can be used in the production of furniture. Steel coils are often used as a raw material in the manufacturing of various types of furniture, such as chairs, tables, and bed frames. Steel coils provide strength, durability, and stability to the furniture, making it suitable for heavy-duty use. Additionally, steel coils can be shaped into different designs and sizes, allowing for versatility in furniture production. The coils can be transformed into various components, such as the frame or support structure of the furniture, providing a solid foundation. Moreover, the use of steel coils in furniture production can enhance the overall aesthetics of the furniture, as they can be finished in different colors and coatings to match the desired style. Overall, steel coils are a common and practical choice for furniture manufacturers due to their strength, durability, and design possibilities.

- Q:How do steel coils contribute to the circular economy?

- Steel coils contribute to the circular economy through their recyclability and reusability. The circular economy aims to minimize waste and promote the continuous use of resources, and steel coils align perfectly with this concept. Firstly, steel coils are made from recycled steel, which reduces the need for extracting raw materials and the associated environmental impact. By using recycled steel, we can conserve natural resources and reduce energy consumption during the manufacturing process. This practice helps to lower carbon emissions and decrease the overall ecological footprint. Furthermore, steel coils can be easily recycled at the end of their lifecycle. Steel is one of the most recycled materials globally, with a high recycling rate. When the coils reach the end of their use, they can be collected, processed, and transformed into new steel products, without losing their properties or quality. This closed-loop recycling system ensures that steel resources are continuously utilized, minimizing the need for virgin steel production. Additionally, steel coils support the circular economy by enabling the creation of durable and long-lasting products. Steel is known for its strength and durability, making it ideal for various applications such as construction, automotive, and packaging. By using steel coils, we can produce products that have a longer lifespan, reducing the need for frequent replacements and minimizing waste generation. Moreover, steel coils can be reused multiple times before they are recycled. They can be rewound, reshaped, or repurposed for different applications, extending their lifecycle and reducing the demand for new coils. This reuse aspect of steel coils contributes to resource efficiency and waste reduction. In summary, steel coils play a significant role in the circular economy by being made from recycled steel, being easily recyclable themselves, enabling the creation of durable products, and promoting reuse. Their contribution helps to close the loop in the steel industry, conserves natural resources, reduces waste generation, and minimizes environmental impact.

- Q:I received a very nice set of stainless steel cookware as a wedding gift. While very pretty, Im finding them almost useless for cooking. Everything sticks, they're difficult to clean, and Im using my old non-stick pans instead. Should I simply leave the stainless out for decortive purposes, or are stainless steel pans better for some applications?

- Why Use Stainless Steel Cookware

- Q:How are steel coils used in the production of HVAC systems?

- Steel coils are used in the production of HVAC systems as they serve as the primary component for heat transfer. These coils are responsible for absorbing heat from the surrounding air and transferring it to cool the interior of a building. Additionally, steel coils are used for the condenser coils in HVAC systems, where they aid in the removal of heat from the refrigerant, allowing for efficient cooling and dehumidification.

- Q:does regular steel rust? or is it all the same.

- Dear, Thank you, am also fine like you then dear yeah is the same.

- Q:What are the dimensions of steel coils used in the industrial machinery industry?

- The dimensions of steel coils used in the industrial machinery industry can vary depending on the specific application and requirements. However, generally speaking, steel coils used in this industry typically have a width ranging from 600 to 2,000 millimeters (24 to 79 inches) and a weight ranging from 2 to 25 metric tons (4,400 to 55,100 pounds). The inner diameter of the coil, known as the core, can range from 508 to 762 millimeters (20 to 30 inches). Additionally, the thickness of the steel coil can range from 0.4 to 25 millimeters (0.016 to 0.98 inches). These dimensions may be subject to variations based on the specific needs and specifications of the machinery being manufactured or used in the industrial machinery industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prepainted Rolled Steel Coil for Roofing Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords