All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

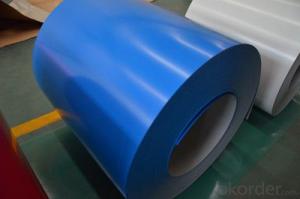

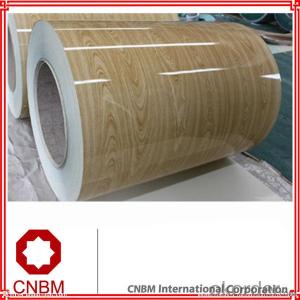

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel coils used in the aerospace industry for the production of satellite and space exploration equipment?

Steel coils are used in the aerospace industry for the production of satellite and space exploration equipment as they provide structural support, strength, and durability. These coils are shaped and formed into various components such as framework, brackets, and panels, which are crucial for the structural integrity of satellites and spacecraft. Additionally, steel coils can be treated and coated to enhance their resistance to extreme temperatures, corrosion, and impact, ensuring the longevity and reliability of aerospace equipment in harsh space environments.

What is the impact of coil cleanliness on the surface finish of coated products?

The impact of coil cleanliness on the surface finish of coated products is significant. A clean coil ensures that no contaminants or debris are present on the surface, which can affect the adhesion and appearance of the coating. If the coil is not properly cleaned, it can lead to imperfections such as uneven coating, streaks, or blemishes on the surface of the product. Therefore, maintaining coil cleanliness is crucial to achieving a high-quality and visually appealing surface finish for coated products.

What is the process of applying paint or coatings to steel coils?

The process of applying paint or coatings to steel coils typically involves several steps. First, the steel coils are cleaned and prepared to remove any dirt, rust, or other impurities. This is usually done through chemical cleaning or mechanical methods such as shot blasting.

Once the steel coils are clean, a primer or pretreatment is applied to enhance adhesion and corrosion resistance. The primer may be a solvent-based or water-based coating, and it is typically applied through roller coating, spray coating, or electrodeposition.

After the primer, one or more layers of the desired paint or coating are applied to the steel coils. This is usually done through a continuous coil coating process, where the coils pass through a series of rollers that evenly apply the paint or coating onto the steel surface. The coatings can be solvent-based, water-based, or powder coatings, depending on the specific requirements.

Once the paint or coating is applied, the steel coils are cured or dried through a heating process. This helps the paint or coating to adhere properly and form a durable finish. The curing temperature and time depend on the type of paint or coating used.

Finally, the coated steel coils are inspected for quality control to ensure even coverage, adhesion, and appearance. This may involve visual inspection, measurement of coating thickness, and various tests to assess adhesion and corrosion resistance.

Overall, the process of applying paint or coatings to steel coils involves cleaning, priming, applying the paint or coating, curing, and inspecting to ensure a high-quality and long-lasting finish.

Wholesale Steel Coils from supplier in Greece

With our strong supply chain network and close partnerships with leading steel manufacturers, we are able to offer competitive prices and high-quality products to our customers in Greece. Whether you are in the construction, automotive, or manufacturing industry, we have the right Steel Coils products to meet your specific requirements.

We understand that every project is unique, and that's why we provide personalized sales and technical support services. Our team of experts is knowledgeable and experienced in the steel industry, and we are dedicated to helping you find the best solutions for your projects. From product selection to logistics management, we will guide you through the entire process to ensure a seamless experience.

At our company, customer satisfaction is our top priority. We strive to exceed your expectations by delivering on-time and providing exceptional customer service. We value long-term relationships with our customers and believe in building trust through transparency and reliability.

Partnering with us means gaining access to a wide range of Steel Coils products, competitive prices, and reliable support services. Whether you need cold-rolled steel coils, hot-dipped galvanized steel coils, or any other type of steel coils, we have you covered.

Contact us today to learn more about our Steel Coils products and services in Greece. Let us be your trusted partner for all your steel coil needs.

We understand that every project is unique, and that's why we provide personalized sales and technical support services. Our team of experts is knowledgeable and experienced in the steel industry, and we are dedicated to helping you find the best solutions for your projects. From product selection to logistics management, we will guide you through the entire process to ensure a seamless experience.

At our company, customer satisfaction is our top priority. We strive to exceed your expectations by delivering on-time and providing exceptional customer service. We value long-term relationships with our customers and believe in building trust through transparency and reliability.

Partnering with us means gaining access to a wide range of Steel Coils products, competitive prices, and reliable support services. Whether you need cold-rolled steel coils, hot-dipped galvanized steel coils, or any other type of steel coils, we have you covered.

Contact us today to learn more about our Steel Coils products and services in Greece. Let us be your trusted partner for all your steel coil needs.