All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does the surface finish of electrolytic tinplate coil affect its printability?

The surface finish of electrolytic tinplate coil greatly affects its printability. A smooth and even surface finish enhances the printability of the tinplate coil, allowing for better ink adhesion and color vibrancy during the printing process. On the other hand, a rough or uneven surface finish can lead to poor print quality, as the ink may not adhere properly and may result in smudging or uneven coverage. Therefore, a high-quality surface finish is crucial for achieving superior printability on electrolytic tinplate coil.

What is the width range of electrolytic tinplate coil?

The width range of electrolytic tinplate coil typically varies between 600 mm to 1,250 mm.

How is the tensile strength of electrolytic tinplate coil tested?

The tensile strength of electrolytic tinplate coil is typically tested by subjecting a sample of the coil to a controlled pulling force until it reaches its breaking point. This test is conducted using a tensile testing machine or equipment that measures the force applied and the resulting elongation or deformation of the sample. The maximum force or load that the sample can withstand before breaking is then recorded as the tensile strength of the electrolytic tinplate coil.

How does the coil handle chemical compatibility?

The coil is designed to handle chemical compatibility by being made from materials that are resistant to corrosion and degradation caused by exposure to various chemicals. This ensures that the coil can safely and effectively transport and contain the chemicals without any negative effects on its performance or structural integrity.

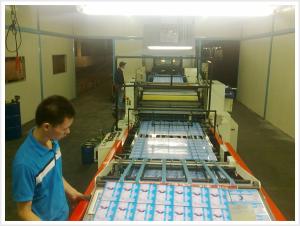

Wholesale Electrolytic Tinplate Coil from supplier in Greece

Our team is dedicated to ensuring customer satisfaction by offering competitive prices, prompt delivery, and reliable technical support. Whether you are in the packaging, canning, or automotive industry, we have the expertise and product range to meet your requirements.

In addition to our focus on Electrolytic Tinplate Coils, we also offer a range of other services and products related to the steel industry. Our parent company, CNBM, is a global leader in the production and distribution of steel products, providing us with access to a vast network of suppliers and resources. This enables us to offer comprehensive procurement services and cater to a wide range of customer needs.

We understand the challenges and complexities of the Greek market and have years of experience in navigating its unique business environment. Our team of experts is well-versed in local regulations, industry trends, and customer preferences, allowing us to provide valuable insights and guidance for your projects.

If you are looking for a reliable supplier of Electrolytic Tinplate Coils in Greece, look no further. Contact us today to discuss your requirements and let us assist you in finding the best solutions for your business.

In addition to our focus on Electrolytic Tinplate Coils, we also offer a range of other services and products related to the steel industry. Our parent company, CNBM, is a global leader in the production and distribution of steel products, providing us with access to a vast network of suppliers and resources. This enables us to offer comprehensive procurement services and cater to a wide range of customer needs.

We understand the challenges and complexities of the Greek market and have years of experience in navigating its unique business environment. Our team of experts is well-versed in local regulations, industry trends, and customer preferences, allowing us to provide valuable insights and guidance for your projects.

If you are looking for a reliable supplier of Electrolytic Tinplate Coils in Greece, look no further. Contact us today to discuss your requirements and let us assist you in finding the best solutions for your business.