All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

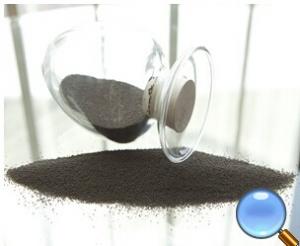

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

What are the disposal methods for refractory materials at the end of their life cycle?

There are several disposal methods for refractory materials at the end of their life cycle. One common method is landfill disposal, where the materials are carefully placed in designated areas to prevent any potential environmental hazards. Another option is recycling, where the refractory materials are processed and reused in new products or applications. Alternatively, some refractory materials can be treated and used as alternative fuels in industrial processes. Ultimately, the disposal method depends on the specific characteristics of the refractory materials and the environmental regulations in place.

How do refractory materials contribute to the efficiency of pharmaceutical manufacturing processes?

Refractory materials contribute to the efficiency of pharmaceutical manufacturing processes by providing heat resistance and insulation, allowing for higher temperatures and faster reactions. This enables more efficient production of pharmaceuticals by reducing process times and improving overall productivity. Additionally, refractory materials help maintain consistent and controlled temperatures, ensuring the quality and stability of the products being manufactured.

How are refractory mortars applied?

Refractory mortars are typically applied by troweling or brushing the mortar mixture onto the desired surface, ensuring a smooth and even coating.

How are refractory materials used in the waste treatment industry?

Refractory materials are used in the waste treatment industry for lining the walls, floors, and roofs of incinerators and other high-temperature equipment. These materials are able to withstand extreme temperatures and harsh chemical environments, preventing damage to the equipment and ensuring efficient waste treatment processes.

Wholesale Refractory Materials from supplier in Greece

Whether you are in need of refractory bricks, castables, or other refractory products, we can supply you with high-quality materials that meet international standards. Our sales team is knowledgeable and experienced, ensuring that you receive the best products for your specific requirements.

In addition to our sales services, we also provide quotations that are tailored to your project needs and budget. We understand the importance of cost-effective solutions, and our team will work closely with you to provide competitive pricing without compromising on quality.

Technical support is another key aspect of our services. Our team of experts is available to provide guidance and assistance throughout your project, from material selection to installation and maintenance. We can help identify the most suitable refractory materials for your application and provide recommendations based on your specific operating conditions.

As a subsidiary of CNBM, we have access to a vast network of resources and expertise. This allows us to ensure a reliable and efficient supply chain, ensuring that your refractory materials are delivered on time and in the quantities required. Our extensive experience in the Greek market also means that we have a deep understanding of local regulations, industry standards, and project requirements.

At our company, we prioritize customer satisfaction and strive to exceed your expectations. We are committed to providing exceptional service, high-quality products, and competitive pricing. Contact us today to discuss your refractory material needs in Greece, and let us be your trusted partner for all your procurement requirements.

In addition to our sales services, we also provide quotations that are tailored to your project needs and budget. We understand the importance of cost-effective solutions, and our team will work closely with you to provide competitive pricing without compromising on quality.

Technical support is another key aspect of our services. Our team of experts is available to provide guidance and assistance throughout your project, from material selection to installation and maintenance. We can help identify the most suitable refractory materials for your application and provide recommendations based on your specific operating conditions.

As a subsidiary of CNBM, we have access to a vast network of resources and expertise. This allows us to ensure a reliable and efficient supply chain, ensuring that your refractory materials are delivered on time and in the quantities required. Our extensive experience in the Greek market also means that we have a deep understanding of local regulations, industry standards, and project requirements.

At our company, we prioritize customer satisfaction and strive to exceed your expectations. We are committed to providing exceptional service, high-quality products, and competitive pricing. Contact us today to discuss your refractory material needs in Greece, and let us be your trusted partner for all your procurement requirements.

Hot Search

- Monolithic Refractories in Sri Lanka

- Ceramic Fiber Products in Turkey

- Refractory Bricks in Belgium

- Raw Materials For Refractory in Israel

- Raw Materials For Refractory in Niger

- Monolithic Refractories in Gabon

- Refractory Bricks in Belize

- Refractory Bricks in Canada

- Raw Materials For Refractory in Guatemala

- Raw Materials For Refractory in Poland