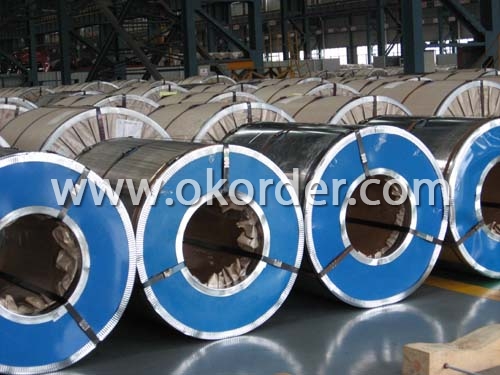

High Quality-Hot Dip Galvanized Steel Coil-Regular Spangle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information Of Hot Dip Galvanized Steel Coil

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

|

Thickness 0.13-0.7mm (BMT) |

|

Width 600-1250mm |

|

Zinc Coating 30-200g/m2 |

|

Internal Diameter 508mm or 610mm |

|

Coil Weight 3-12MT |

|

Quality Commercial and structural quality |

|

Spangle Regular Spangle |

|

Surface Treatment Oiled/dry , Skin pass/non-skin pass ,Chromated/non-chromated |

|

Standard JIS G 3302, ASTM A 653M, EN 10327 |

|

Steel Grade SGCC, CS, FS, SS, LFQ, DX51D+Z , S280GD |

Chemical Composition Of Hot Dip Galvanized Steel Coil

|

C |

Si |

Mn |

P |

Si |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

0.006%-0.009% |

Technical Data Of Hot Dip Galvanized Steel Coil

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Out-of-square |

not exceed 1% Flatness |

|

Bow |

15mmmax |

|

Edge Wave |

9mmmax |

|

Centre Buckle |

8mmmax |

|

Bending At 180 Degree |

No crack, purling and fraction |

Application Of Hot Dip Galvanized Steel Coil

Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering

With GI as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Packaging & Delivery Of Hot Dip Galvanized Steel Coil

Anti-damp paper inside full wrapped with plastic film, iron sheet outside on wooden pallet in 20 feet container with 25mt.

- Q:i mean the properties include the elasticity, impact load and ductility. am doing assignment about the perfect material that should be possessed by spring and i found alloy steel is the perfect and am confused whether stainless steel is the same with alloy steel ?

- Is Stainless Steel An Alloy

- Q:I bought a damascus steel knife. It will be used for display. Nothing like hunting/skinning. If It is just sitting around, will it rust? (assuming that it isn't getting wet) Thanks for the help.

- From that point of view the strength or edge-holding ability means very little. Specifically, the bushcraft knife is pattern welded steel. True damascus or Wootz steel is something you'll only find in museums and private collections. they stopped making it several hundred years ago. Despite what many people have claimed, Wootz damascus was inferior to modern tool steels in every respect. It was a brittle, dirty material.

- Q:What are the different types of steel coil surface protection methods?

- There are several types of steel coil surface protection methods, including oiling, painting, galvanizing, and plastic film coating.

- Q:What are the main factors that affect the corrosion resistance of steel coils?

- The main factors that affect the corrosion resistance of steel coils include the composition of the steel, the presence of impurities, the type and thickness of the protective coating, exposure to corrosive environments (such as moisture, chemicals, and salt), and the presence of physical damage or scratches on the surface of the coils.

- Q:Is Carbon Steel strong for swords?

- Yes. Most high quality knives are made of carbon steel versus say stainless steel. High strength carbon steel holds an edge well and is strong.

- Q:What is the role of steel coils in the manufacturing of appliances?

- Steel coils play a crucial role in the manufacturing of appliances as they serve as the primary material for constructing the appliance's body and various components. The coils are processed, shaped, and transformed into different parts, such as the outer casing, inner structures, and internal components, providing strength, durability, and stability to the appliances. Additionally, the steel coils can be easily customized to meet specific design requirements, ensuring the appliances are efficient, reliable, and capable of withstanding the demands of daily use.

- Q:I just bought a used Taurus 85 stainless 38 spl revolver, it's about 25 years old but looks like new. This is my first stainless steel gun. I'm wondering if there's any special things I need to be aware of or cleaning methods? I'm also wondering if stainless steel could rust? in theory stainless means it cannot get stained or rusty. I have a chrome bore AK, cleaning is always super easy, wondering of cleaning a SS revolver would be the same.

- Yes, stainless steel will rust. It is not rust proof, it is rust resistant. You still should oil your gun after you shoot it.

- Q:How are steel coils used in the automotive industry?

- Steel coils are used in the automotive industry to manufacture various components, such as body panels, frames, and suspension parts. These coils are transformed into flat sheets or molded into different shapes to meet the specific requirements of each component. The high strength and durability of steel make it an ideal material for ensuring safety and structural integrity in vehicles.

- Q:What are the common methods of welding steel coils?

- The common methods of welding steel coils include arc welding, resistance welding, and laser welding.

- Q:Does anyone know the lyrics to steel driving man by Dailey and Vincent. I would really appreciate it

- I okorder /

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 2010 |

| Annual Output Value | |

| Main Markets | 33.03% Southeast Asia 33.03% South America 20.18% Africa 13.76% Mid East |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin Port, China |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | Above 100 People |

| Language Spoken: | Chinese, English |

| b)Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Low |

Send your message to us

High Quality-Hot Dip Galvanized Steel Coil-Regular Spangle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords