All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel coils tested for their resistance to extreme temperatures and fire resistance in the construction industry?

Steel coils used in the construction industry are typically tested for their resistance to extreme temperatures and fire resistance through a process called fire testing. This testing involves subjecting the steel coils to high temperatures in a controlled environment, such as a furnace, and monitoring their performance. The coils are evaluated based on criteria like the time it takes for them to reach a certain temperature, their structural integrity under heat, and their ability to withstand fire without significant damage. These tests help ensure that the steel coils meet the necessary fire safety standards and can be safely used in construction projects.

What measures are in place to maintain coil flatness during transportation in the manufacturing of metal railings and fences?

In the manufacturing of metal railings and fences, several measures are taken to maintain coil flatness during transportation. Firstly, specialized packaging materials such as wooden crates or protective cardboard sleeves are used to securely hold and protect the coils. These packaging materials offer cushioning and stability, preventing any excessive movement or impact that could lead to coil deformation. Additionally, the coils are often secured with strapping or banding to further enhance stability and prevent shifting during transportation. Furthermore, specific handling procedures are implemented to ensure the coils are lifted and loaded onto trucks or containers using appropriate equipment and techniques, minimizing the risk of bending or twisting. Regular quality checks and inspections are conducted before and after transportation to identify any potential issues and rectify them promptly. Overall, these measures collectively play a crucial role in maintaining coil flatness and ensuring the integrity of the metal railings and fences throughout the transportation process.

How are steel coils weighed accurately?

Steel coils are weighed accurately using industrial weighing scales or load cells. These devices are specifically designed to handle heavy loads and provide precise measurements. The steel coil is placed on the scale or load cell, and the weight is displayed on a digital or analog readout. This ensures accurate and reliable weighing of steel coils.

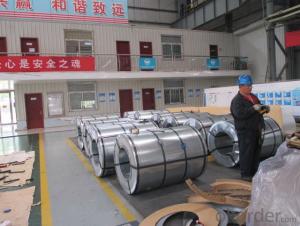

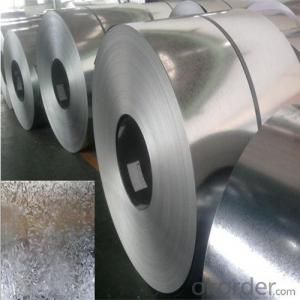

Wholesale Steel Coils from supplier in Mozambique

Whether you require galvanized steel coils, cold-rolled steel coils, or any other type of steel coils, we have the capacity to fulfill your needs. Our products are sourced from reliable manufacturers and undergo strict quality control measures to ensure that they meet international standards. We understand the importance of timely delivery, and our logistics team ensures that your orders are delivered on time and in excellent condition.

In addition to our high-quality products, we also provide exceptional sales support services. Our dedicated sales team in Mozambique is well-trained and knowledgeable, and they will assist you in finding the right steel coils products for your specific requirements. They will also provide you with competitive pricing and timely quotations, allowing you to make informed decisions.

Technical support is another area where we excel. Our team of experienced engineers is available to provide technical advice and assistance throughout your project. Whether you need assistance in selecting the appropriate steel coils for your application or require guidance in installation and maintenance, our technical support team is here to help.

At our Steel Coils supplier, we value our relationships with our clients and strive to exceed their expectations. We believe in building long-term partnerships based on trust, reliability, and exceptional service. With our vast resources, expertise, and dedication, we are your trusted partner for all your steel coils needs in Mozambique. Contact us today to discuss your requirements and experience the difference of working with a reputable and reliable supplier.

In addition to our high-quality products, we also provide exceptional sales support services. Our dedicated sales team in Mozambique is well-trained and knowledgeable, and they will assist you in finding the right steel coils products for your specific requirements. They will also provide you with competitive pricing and timely quotations, allowing you to make informed decisions.

Technical support is another area where we excel. Our team of experienced engineers is available to provide technical advice and assistance throughout your project. Whether you need assistance in selecting the appropriate steel coils for your application or require guidance in installation and maintenance, our technical support team is here to help.

At our Steel Coils supplier, we value our relationships with our clients and strive to exceed their expectations. We believe in building long-term partnerships based on trust, reliability, and exceptional service. With our vast resources, expertise, and dedication, we are your trusted partner for all your steel coils needs in Mozambique. Contact us today to discuss your requirements and experience the difference of working with a reputable and reliable supplier.