All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

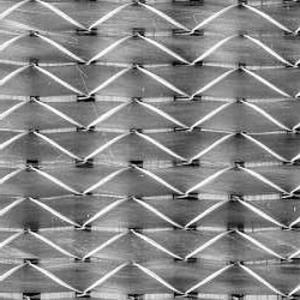

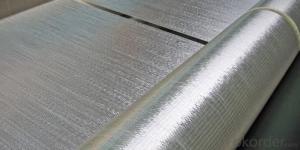

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the factors to consider when selecting fiberglass mat tissue for a specific application?

When selecting fiberglass mat tissue for a specific application, there are several factors to consider.

Firstly, it is important to evaluate the strength and durability requirements of the application. This involves considering the weight, thickness, and tensile strength of the fiberglass mat tissue. A heavier and thicker tissue may be needed for applications that require higher strength and durability.

Secondly, the compatibility of the fiberglass mat tissue with the intended resin system should be assessed. The tissue should be able to effectively bond with the resin and provide good wet-out properties. Compatibility is crucial to ensure proper adhesion and overall performance of the final product.

Additionally, the desired finish or surface appearance of the application should be taken into account. Some fiberglass mat tissues have a smoother surface finish, while others have a more textured appearance. The desired finish can influence the choice of tissue to achieve the desired aesthetic outcome.

Moreover, the specific application's environmental conditions must be considered. Factors such as temperature, moisture, and chemical exposure can affect the performance and longevity of the fiberglass mat tissue. It is important to select a tissue that can withstand the intended environmental conditions and maintain its properties over time.

Lastly, the cost and availability of the fiberglass mat tissue should be considered. The selected tissue should fall within the project's budget and be readily available from reliable suppliers.

Considering these factors will help ensure that the chosen fiberglass mat tissue is suitable for the specific application and will meet the desired performance requirements.

Does fiberglass mat tissue require any special surface coatings after application?

No, fiberglass mat tissue does not require any special surface coatings after application.

Can fiberglass mat tissue be used for reinforcing architectural structures?

Yes, fiberglass mat tissue can be used for reinforcing architectural structures. It is commonly used in construction and architectural applications to strengthen concrete, masonry, and other building materials. The high strength and durability of fiberglass mat tissue make it an ideal choice for enhancing the structural integrity of architectural projects.

Is fiberglass mat tissue resistant to insects and pests?

Yes, fiberglass mat tissue is generally resistant to insects and pests due to its composition and properties. The fiberglass material is not conducive to feeding or nesting for most insects and pests, making it an unfavorable environment for them to thrive.

Wholesale Fiberglass Mat Tissue from supplier in Mozambique

Our team of experts can assist you in selecting the right Fiberglass Mat Tissue products for your specific needs, ensuring that you receive the best solutions for your projects. We understand the importance of timely delivery and strive to provide efficient logistics services to ensure that your orders are delivered on time and in excellent condition.

In addition to our high-quality products and reliable services, we also offer technical support to assist you with any questions or concerns you may have regarding the application and installation of Fiberglass Mat Tissue. Our knowledgeable team is always ready to provide guidance and assistance to ensure the success of your projects.

As a subsidiary of CNBM, we have access to a wide range of resources and expertise, allowing us to offer you a comprehensive range of products and services. Our partnership with CNBM also ensures that our products meet the highest quality standards and adhere to international regulations.

We take pride in our commitment to customer satisfaction and strive to build long-term relationships with our clients based on trust and reliability. Whether you are a contractor, distributor, or end-user, we are dedicated to providing you with the best products and services in the industry.

Contact us today to learn more about our Fiberglass Mat Tissue products and how we can assist you with your projects in Mozambique.

In addition to our high-quality products and reliable services, we also offer technical support to assist you with any questions or concerns you may have regarding the application and installation of Fiberglass Mat Tissue. Our knowledgeable team is always ready to provide guidance and assistance to ensure the success of your projects.

As a subsidiary of CNBM, we have access to a wide range of resources and expertise, allowing us to offer you a comprehensive range of products and services. Our partnership with CNBM also ensures that our products meet the highest quality standards and adhere to international regulations.

We take pride in our commitment to customer satisfaction and strive to build long-term relationships with our clients based on trust and reliability. Whether you are a contractor, distributor, or end-user, we are dedicated to providing you with the best products and services in the industry.

Contact us today to learn more about our Fiberglass Mat Tissue products and how we can assist you with your projects in Mozambique.

Hot Search

- Fiberglass Chopped Strand in Somalia

- Fiberglass Mesh Cloth in Jordan

- Composite Pipes in Uganda

- FRP Pultrusion Profiles in Palau

- Fiberglass Mat Tissue in Timor Leste

- Fiberglass Fabrics in Albania

- Fiberglass Mesh in Kuwait

- Composite Tank in Liechtenstein

- Fiberglass Mesh tape in Burundi

- Polymer in Angola