All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are aluminum strips used in the aerospace industry to reduce weight and improve fuel efficiency?

Aluminum strips are used in the aerospace industry due to their lightweight properties, which helps reduce the overall weight of the aircraft. By substituting heavier materials with aluminum strips in various components such as fuselage, wings, and structural elements, the overall weight of the aircraft is decreased. This weight reduction directly translates to improved fuel efficiency, as the aircraft requires less fuel to generate the required thrust and lift. Additionally, aluminum strips offer good strength-to-weight ratio, corrosion resistance, and ease of fabrication, making them an ideal choice for enhancing fuel efficiency in the aerospace industry.

How do you minimize the risk of delamination in multi-layer aluminum strip products?

To minimize the risk of delamination in multi-layer aluminum strip products, several measures can be taken.

Firstly, it is important to ensure that the aluminum strips are properly cleaned and free from any contaminants before the lamination process. This can be achieved through thorough surface preparation techniques such as degreasing and etching.

Secondly, the choice of adhesive used for lamination plays a critical role in preventing delamination. Selecting an adhesive with high bonding strength and compatibility with aluminum is essential. It is also important to ensure that the adhesive is applied uniformly and in the correct amount to promote strong and reliable bonding.

Additionally, controlling the lamination process parameters such as temperature, pressure, and curing time is crucial. These parameters should be optimized to create a strong bond between the aluminum layers while avoiding excessive stress or overheating that can lead to delamination.

Furthermore, regular quality checks and inspections throughout the manufacturing process can help identify any potential issues or defects that may lead to delamination. This allows for corrective actions to be taken promptly, reducing the risk of delamination.

Overall, minimizing the risk of delamination in multi-layer aluminum strip products requires a combination of proper surface preparation, careful adhesive selection and application, optimal lamination process parameters, and diligent quality control measures.

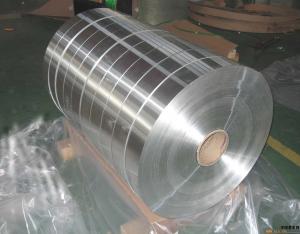

Wholesale Aluminum Strips from supplier in Mozambique

Thank you for considering us as your trusted supplier of Aluminum Strips in Mozambique. We understand the importance of reliable and high-quality products for your projects, and we are committed to meeting your requirements.

With our affiliation with CNBM, a Fortune Global 500 company, you can be assured of our commitment to excellence and professionalism. Our team of experts is dedicated to providing you with the best solutions and technical support, ensuring that your projects are successful.

We offer a wide range of Aluminum Strips products, including standard and customized options, to cater to your specific needs. Our years of market development in Mozambique have allowed us to understand the unique requirements of our customers, enabling us to provide tailored recommendations and support.

When you choose us as your partner, you can expect exceptional customer service and a seamless procurement process. We prioritize customer satisfaction and strive to exceed your expectations in every interaction.

Contact us today to discuss your Aluminum Strips requirements and let us assist you in achieving your project goals in Mozambique. We look forward to working with you and building a long-lasting partnership.

With our affiliation with CNBM, a Fortune Global 500 company, you can be assured of our commitment to excellence and professionalism. Our team of experts is dedicated to providing you with the best solutions and technical support, ensuring that your projects are successful.

We offer a wide range of Aluminum Strips products, including standard and customized options, to cater to your specific needs. Our years of market development in Mozambique have allowed us to understand the unique requirements of our customers, enabling us to provide tailored recommendations and support.

When you choose us as your partner, you can expect exceptional customer service and a seamless procurement process. We prioritize customer satisfaction and strive to exceed your expectations in every interaction.

Contact us today to discuss your Aluminum Strips requirements and let us assist you in achieving your project goals in Mozambique. We look forward to working with you and building a long-lasting partnership.