All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

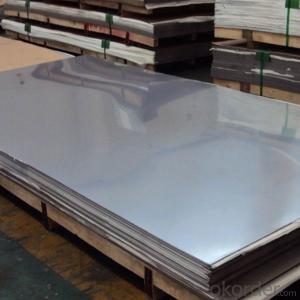

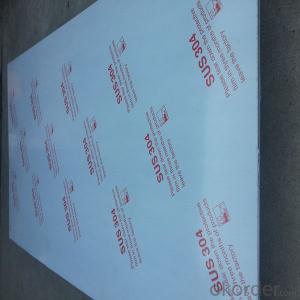

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different fabrication techniques used for stainless steel sheet?

Some of the different fabrication techniques used for stainless steel sheet include cutting, bending, welding, and polishing. Cutting techniques can include shearing, sawing, or laser cutting. Bending techniques can involve press brakes or roll forming. Welding techniques such as TIG, MIG, or spot welding can be used to join stainless steel sheets together. Polishing techniques can range from mechanical polishing to electro-polishing, depending on the desired finish.

Can stainless steel sheet be used in the construction industry?

Yes, stainless steel sheet can be used in the construction industry. It is commonly used for various applications such as roofing, wall cladding, structural supports, and decorative finishes due to its durability, corrosion resistance, and aesthetic appeal.

What is the torsional strength of stainless steel sheets?

The torsional strength of stainless steel sheets varies depending on the specific grade and thickness of the material. However, stainless steel is known for its high strength and excellent resistance to torsional forces, making it a suitable choice for applications requiring torsional strength.

How does stainless steel sheet perform in acidic environments?

Stainless steel sheet performs exceptionally well in acidic environments due to its high resistance to corrosion. The chromium content in stainless steel forms a protective layer that prevents the metal from reacting with acids, making it highly durable and reliable in such conditions.

Wholesale Stainless Steel Sheet from supplier in Mozambique

Some possible improvements to the text could include:

1. Adding specific details about the range of Stainless Steel Sheet products offered, such as thicknesses, finishes, and grades.

2. Including information about any additional services provided, such as cutting, bending, or fabrication.

3. Highlighting any certifications or accreditations that the company holds, such as ISO 9001 or CE marking.

4. Providing examples of past projects or clients to showcase the company's experience and track record.

5. Emphasizing the company's commitment to sustainability, if applicable, such as using recycled materials or implementing environmentally friendly production processes.

6. Including testimonials or customer reviews to demonstrate the company's reputation and customer satisfaction.

7. Mentioning any unique selling points or competitive advantages, such as competitive pricing, quick turnaround times, or a wide distribution network.

8. Providing contact information or a call to action for interested customers to get in touch or request a quote.

1. Adding specific details about the range of Stainless Steel Sheet products offered, such as thicknesses, finishes, and grades.

2. Including information about any additional services provided, such as cutting, bending, or fabrication.

3. Highlighting any certifications or accreditations that the company holds, such as ISO 9001 or CE marking.

4. Providing examples of past projects or clients to showcase the company's experience and track record.

5. Emphasizing the company's commitment to sustainability, if applicable, such as using recycled materials or implementing environmentally friendly production processes.

6. Including testimonials or customer reviews to demonstrate the company's reputation and customer satisfaction.

7. Mentioning any unique selling points or competitive advantages, such as competitive pricing, quick turnaround times, or a wide distribution network.

8. Providing contact information or a call to action for interested customers to get in touch or request a quote.