All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

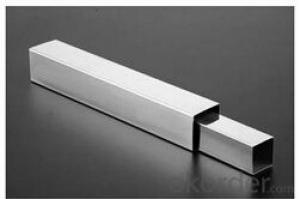

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is cold-rolled steel used in the production of lighting fixtures?

Cold-rolled steel is commonly used in the production of lighting fixtures due to its durability, strength, and versatility. It is often used to manufacture the structural components of lighting fixtures, such as the frames, brackets, and housings. The cold-rolling process ensures a smooth and consistent surface finish, making it ideal for painting or coating to achieve the desired aesthetic appearance. Additionally, cold-rolled steel's malleability allows for intricate designs and shapes, enabling manufacturers to create stylish and unique lighting fixtures.

What are the energy savings associated with using cold-rolled steel?

The energy savings associated with using cold-rolled steel are significant. The cold-rolling process requires less energy compared to the hot-rolling process used for traditional steel production. Cold-rolling involves subjecting the steel to lower temperatures, which reduces the need for high energy consumption for heating and re-heating the metal. Additionally, cold-rolled steel can be produced with thinner gauges, resulting in reduced material usage and further energy savings. Overall, the use of cold-rolled steel helps to conserve energy and reduce carbon emissions in the manufacturing process.

How is cold-rolled steel used in the aerospace sector for aircraft components?

Cold-rolled steel is commonly used in the aerospace sector for manufacturing various aircraft components. Its high strength, durability, and excellent dimensional accuracy make it ideal for applications where precision and reliability are crucial. Cold-rolled steel is used to create structural components such as fuselage frames, landing gear, wing spars, and engine mounts. Its superior mechanical properties allow for lighter weight designs without compromising on strength, improving fuel efficiency and aircraft performance. Additionally, the smooth surface finish achieved through the cold-rolling process enhances aerodynamic performance and reduces drag. Overall, cold-rolled steel plays a vital role in ensuring the safety, efficiency, and longevity of aircraft in the aerospace industry.

Wholesale Cold Rolled Steel from supplier in Brazil

Whether you need Cold Rolled Steel for construction, automotive, or manufacturing purposes, we have the expertise to meet your specific needs. Our product range includes various grades and thicknesses of Cold Rolled Steel, ensuring that you can find the perfect solution for your project.

In addition to supplying high-quality Cold Rolled Steel, we also offer comprehensive sales, quotation, and technical support services. Our dedicated team of professionals is available to assist you throughout the procurement process, ensuring a smooth and hassle-free experience.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide you with all-inclusive Cold Rolled Steel procurement solutions in Brazil. Our strong global network enables us to source the best quality products at competitive prices, ensuring that you receive value for your investment.

Furthermore, our years of market experience in Brazil have enabled us to gain valuable insights and expertise. We understand the local regulations, market dynamics, and customer preferences, allowing us to offer tailored solutions that meet your specific requirements. Whether you are a small business or a large corporation, we can help enhance your projects and drive success.

Partner with us for your Cold Rolled Steel needs in Brazil, and experience the benefits of our comprehensive range of products, sales support, technical expertise, and market insights. We are committed to delivering excellence and exceeding your expectations. Contact us today to discuss your requirements and explore how we can assist you.

In addition to supplying high-quality Cold Rolled Steel, we also offer comprehensive sales, quotation, and technical support services. Our dedicated team of professionals is available to assist you throughout the procurement process, ensuring a smooth and hassle-free experience.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide you with all-inclusive Cold Rolled Steel procurement solutions in Brazil. Our strong global network enables us to source the best quality products at competitive prices, ensuring that you receive value for your investment.

Furthermore, our years of market experience in Brazil have enabled us to gain valuable insights and expertise. We understand the local regulations, market dynamics, and customer preferences, allowing us to offer tailored solutions that meet your specific requirements. Whether you are a small business or a large corporation, we can help enhance your projects and drive success.

Partner with us for your Cold Rolled Steel needs in Brazil, and experience the benefits of our comprehensive range of products, sales support, technical expertise, and market insights. We are committed to delivering excellence and exceeding your expectations. Contact us today to discuss your requirements and explore how we can assist you.