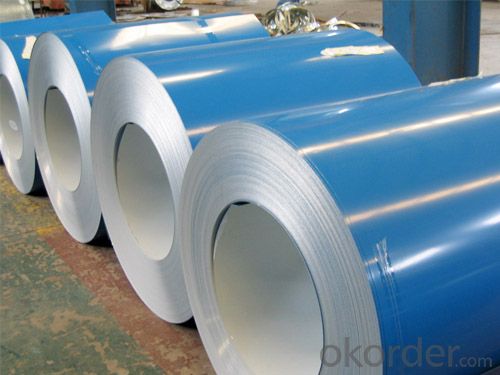

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price color is blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, blue color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Can steel coils be coated with fire-resistant materials?

- Yes, steel coils can be coated with fire-resistant materials. This coating can provide an extra layer of protection against fire hazards, reducing the risk of ignition and spread.

- Q:What are the key factors affecting the strength of a steel coil?

- The key factors affecting the strength of a steel coil include the grade and composition of the steel used, the manufacturing process and techniques employed, as well as the heat treatment and cooling methods implemented. Other factors such as the thickness and width of the coil, as well as any mechanical or surface treatments applied, can also influence its strength.

- Q:Are Steel Building Kits really helpful while erecting a steel building?

- I put up a 30'x40' Mueller Steel Building from a bolt together kit 6 yrs ago. Fully insulated, 2 10'x10' roll up doors, 1 walk thru door, 3 windows, 2' overhang all around, and gutters. The building price minus the slab was about $9500. The only special equipment was a neighbor's large Farmall with a hay spike on the FEL that we used to lift the trusses in place. Then it was mainly cordless drills to put in LOTS of self tapping screws, circular saw with metal cutting blade, tall ladders, etc. Had help putting up the trusses and putting up the roof panels. Everything else I did by myself. Took about 6 wks, but that was only working weekends and maybe 3 evenings a week since that land is 30 miles from my house. Would have gone a lot faster with at least one helper.

- Q:How are steel coils used in the production of building facades?

- Steel coils are used in the production of building facades as they are rolled into flat sheets and then cut into various sizes and shapes. These steel sheets are then formed, fabricated, and installed to create the outer layer of a building. The steel coils provide strength, durability, and a sleek, modern appearance to the facades, making them an essential component in the construction industry.

- Q:I know that they have steel shot in smaller sized pellets....say, number 4 shot. I guess it's for waterfowl, etc.Do they make steel buckshot? If not, why not? Would the pellets be too heavy? Wouldn't they have excellent penetration ability?

- This Site Might Help You. RE: Do they manufacture steel buckshot? I know that they have steel shot in smaller sized pellets....say, number 4 shot. I guess it's for waterfowl, etc. Do they make steel buckshot? If not, why not? Would the pellets be too heavy? Wouldn't they have excellent penetration ability?

- Q:What are the uses of galvanized steel coils?

- Galvanized steel coils are widely used in various industries for their durability and corrosion resistance. They are commonly used in construction for roofing, siding, and structural components. They are also used in the automotive industry for manufacturing parts such as body panels, chassis, and exhaust systems. Additionally, galvanized steel coils find applications in the manufacturing of appliances, agricultural equipment, and electrical enclosures.

- Q:What are the challenges in coil edge trimming for narrow strips?

- There are several challenges in coil edge trimming for narrow strips. Firstly, one of the main challenges is maintaining accuracy and precision during the trimming process. Narrow strips require a high level of precision to ensure that the edges are trimmed evenly and smoothly. Any deviation from this precision can result in uneven edges or burrs, which can affect the overall quality of the strip. Secondly, there is the challenge of controlling the strip tension. Narrow strips are more prone to tension issues, as they have less surface area to distribute the tension evenly. This can lead to problems such as strip breakage or stretching, which can impact the final product's quality. Another challenge is avoiding material waste. Narrow strips often have a smaller margin for error, meaning that any mistakes in the trimming process can result in a significant amount of wasted material. Minimizing material waste is crucial for cost-effectiveness and sustainable manufacturing practices. Additionally, maintaining a high production rate can be challenging when working with narrow strips. The trimming equipment needs to be able to handle the high speed required for efficient production while still maintaining accuracy and precision. This requires the use of advanced machinery and technology to ensure smooth and efficient operations. Lastly, the handling and transportation of narrow strips can also pose challenges. Due to their small size, narrow strips are more susceptible to damage during handling and transportation. Proper care and handling techniques need to be implemented to prevent any potential damage, which could affect the quality of the final product. Overall, the challenges in coil edge trimming for narrow strips revolve around precision, tension control, material waste, production rate, and handling. Overcoming these challenges requires the use of advanced technology, skilled operators, and careful attention to detail throughout the entire process.

- Q:so my parents gave me stainless steel cookware for christmas and the first time i used it i cooked chicken. it stuck to the pan and where the oil splattered it cooked on and turned it dark black and brownish. and the bottom too. i don't cook with it because i don't want to burn it on anymore but i don't know how to clean it. how do i cook without burning anything, aside from a lower flame and how on earth do i get the stains on. i've tried almost everything too! thanks.

- I, too, don't like stainless steel because it is so hard to keep clean. Bar Keeper's Friend really does become your friend when you cook on stainless steel. It will remove the burnt on food, remove the dark brown stains and keep it looking new, however. And, it won't void most manufacturer's warranties on the cookware. It just takes the elbow grease to do it every time you use it. I found it is necessary to use more olive oil than you think is necessary, a lower flame than most recipes call for and a lot of patience if you plan to use it on a daily basis. I went back to my non-stick Calphelon because I am not a patient woman, I like instantaneous gratification and hate scrubbing pots and pans!

- Q:How are steel coils used in the manufacturing of construction cranes?

- Steel coils are used in the manufacturing of construction cranes to provide structural strength and durability. These coils are typically shaped and welded to form the main framework of the crane, which supports heavy loads and ensures stability during operation. Additionally, the steel coils are used to fabricate various components such as the boom, jib, and counterweights, which contribute to the crane's lifting capacity and overall functionality.

- Q:How are steel coils used in the production of construction machinery?

- Steel coils are used in the production of construction machinery as they are a primary raw material for manufacturing various components such as structural frames, chassis, and other heavy-duty parts. These coils are typically processed and fabricated through cutting, bending, welding, and shaping techniques to create the required components that form the foundation of construction machinery.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price color is blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords