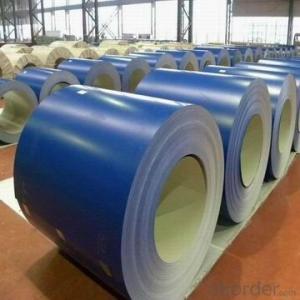

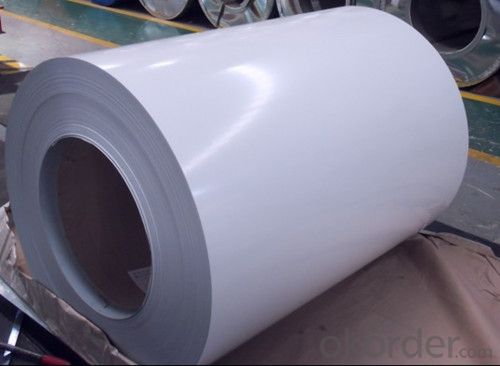

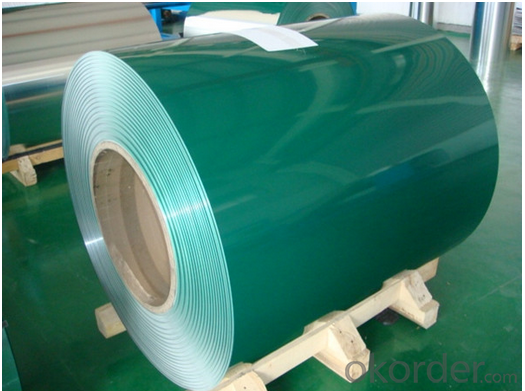

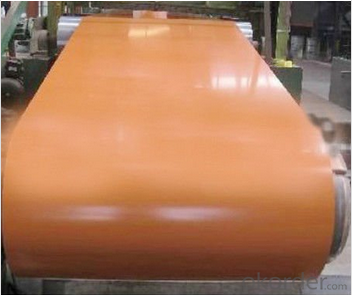

Popular PPGI/PPGL Color Coated Coils(0.12-1.5mm)*(600-1250mm)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.PPGL Color Coated Coils Features:

. A strong anti-corrosion properties, good corrosion resistance. The use of hot dipped galvanized steel substrates for the Color Painted steel coil, with the exception of zinc have anti-corrosion layer, a layer of coatings have seized coverage and protection, allowing effective anti-rust products, galvanized coil about life than double.

. A good cold-formed molding processing, users can directly processed into finished products. Substituting wood to steel, easy to transport, and efficient construction, energy conservation.

2.Applications of PPGL Color Coated Coils

* Used as roof panel, wall panel in steel structure in warehouse,

factories exhibition hall container houses, cold storage

*It is also mainly used in light industry, automobile, construction,

animal husbandry, fishery and commerce, etc,

3.Product information:

| PRODUCT | PPGL Color Coated Coils |

| STANDARD | GB/T-12754: 2006, JIS330, ASTM A653, JIS G330, GB/T2518, ASTM A792, JIS G3321, JIS G3317 |

| BASE METAL | Hot dipped Galvanized steel sheet/coil, Hot dipped Galvalume steel sheet/coil |

| EQUIPMENT | Double coating double baking; three coating three painting |

| SUPPLY CAPACITY | 500,000 Tons per Year |

| SIZE | Thickness: 0.3mm-1.0 mm,thickness tolerance: +/- 0.02mm Width : 700mm—1250mm |

| ZINC COATING | 30g/m2-150g/m2 |

| PAINT THICKNESS | Top Side: 10-25 microns; Back Side: 4-8 microns |

| COIL WGT | Normally 5 Tons per Coil, aslo as required by customer |

| COIL ID | 508mm/610mm |

| SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

4.PPGL Color Coated Coils image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:PLS tell me all Foam Steel Characteristics and use?Thanks

- Foam steel [often steel foam] is used in applications that require light weight but high rigidity and strength. Watertight doors on modern ships are often made of foam steel. Pressure doors on aircraft are possible uses. As we keep striving for lighter weights in cars, foam steel might have some useful applications in bodies. There is a technical paper online that is in .pdf format that has a good discussion of the process and characteristics of foam steel.

- Q:I mean 4 inch thick steel like was used in the WTC buildings, especially WTC 7 which did not get hit by a plane. Can carpeting, desk chairs, water coolers and dry erase boards burn hot enough and long enough to melt steel that is normally made in a blast furnace?

- they shouldn't, provided that they are properly fireproofed. in the case of the wtc the explosion of the plane instantaneously removed the spray on fireproofing in the members. the unprotected members then melted. had the fireproofing remained on the members the office equipment etc most likely would have burnt itself out before the members became comprimised.

- Q:Are steel or graphite clubs better?

- I use steel shaft golf clubs (mens so called clubs) I find the garphite shaft that is typically used for womens clubs is too light and I have a messy swing Callaway Big Bertha is GREAT .... very forgiving club and the oversized clubhead is great for beginners up to advanced. *****FOR MEN - STEEL******* no graphite (just the woods have graphite shafts but the irons are steel

- Q:How are steel coils inspected for flatness?

- Steel coils are inspected for flatness using various methods, such as visual inspection, measuring the crown or center buckle, and conducting a straight edge test. These techniques help assess any deviations or unevenness in the coil's surface, ensuring that it meets the required flatness standards.

- Q:Can cold rolled galvanized steel coils be acid washed after oxidation?

- If it has been galvanized, it can not be pickled, and if it is pickled, it may corrode the zinc layer

- Q:How are steel coils used in the production of fencing materials?

- Steel coils are used in the production of fencing materials by being unwound and flattened to create the wire used for fencing. The steel wire is then further processed and shaped into different forms, such as chain link or barbed wire, to meet specific fencing needs.

- Q:Can steel coils be coated with magnetically attractive materials?

- Yes, steel coils can be coated with magnetically attractive materials.

- Q:How are steel coils used in the production of wire products?

- Wire products rely heavily on steel coils, which are indispensable in their production. These coils, typically crafted from high-quality steel, serve as raw materials in wire drawing processes. Wire drawing, a manufacturing technique, diminishes the coil's diameter, converting it into diverse wire products. The initial step involves the placement of a steel coil onto a wire drawing machine. Subsequently, the machine pulls the coil through a sequence of progressively smaller dies. Each die the coil passes through reduces the wire's diameter, resulting in a more slender and elongated wire strand. This process can be repeated multiple times until the desired wire thickness is achieved. Once the wire is drawn, it can undergo further processing to create an array of wire products, including fencing, nails, screws, springs, and electrical wires. The wire can be cut into specific lengths, bent, or shaped to suit its intended purpose. Moreover, it can undergo treatments like galvanizing or coating to enhance its durability and resistance to corrosion. Steel coils offer numerous advantages in wire product manufacturing. Firstly, they provide a consistent and uniform material, ensuring the resulting wire products possess consistent quality and performance. Secondly, steel coils are easily transportable and can be stored efficiently, making them a cost-effective choice for manufacturers. Lastly, the versatility of steel enables the production of wire products with varying tensile strengths and properties to meet specific industry requirements. To summarize, steel coils play an essential role in wire product manufacturing. They serve as the primary raw material in wire drawing processes, where they undergo a series of reduction steps to be transformed into diverse wire products. These wire products find applications across various industries, solidifying the indispensability of steel coils in the manufacturing sector.

- Q:How are steel coils inspected for flatness variations?

- Steel coils are inspected for flatness variations using various methods such as visual inspection, measurement techniques, and automated systems. Visual inspection involves trained personnel visually inspecting the coil's surface for any irregularities or deviations from flatness. Measurement techniques involve using precision instruments such as straight edges, feeler gauges, or laser sensors to measure the flatness at different points along the coil's length. Automated systems use advanced technologies like laser scanning or optical sensors to quickly and accurately detect any flatness variations in the steel coils. These inspections help ensure that the coils meet the required flatness specifications and quality standards.

- Q:I am wondering if i can use my western guitar as a kind of steel-guitar, read something about it on Wikipedia.

- If you decide to get a true pedal steel, plan on spending some big money. Look on eBay for a Carter Starter. It will be the best guitar to start on...and not outgrow too fast.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Popular PPGI/PPGL Color Coated Coils(0.12-1.5mm)*(600-1250mm)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords