Polycarboxylate Superplasticizer AM-200 for Concrete Admixture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

AM-200 (economic) is developed by our company is an environment-friendly polycarboxylate ethers high performance water reducer, it has a high water reducing rate, low cost, low alkali,suitable for a variety of ready-mixed and in-situ concrete of industrial and civil constructions which require lower level of coagulation slump, especially in the commercial concrete application .Good economy.

Features and Benefits

1 ,It has high water reducing ratio (up to 35%), good dispersion, and provide a guarantee to improve concrete performance, increase the strength of concrete, save cement.

2, It has generally mobility sustained, by composite a certain percentage with other polycarboxylate high range water reducer, it can increase sustained performance, and saving costs.

3, Mixed concrete can significantly improve the workability of the concrete mixture; It can reduce the viscosity of high performance concrete effectively, improve the performance of construction, not be easy to segregation and bleeding, and easy pumping.

4 ,This product can improve the early strength and late strength of hardened concrete, impermeability and frost resistance, and improve the contractile properties ,creep performance and durability. It reduces the rate of carbonation of concrete, alkali- aggregate reaction.

5 ,Due to low content of alkali and chlorine ion, it improves the durability of concrete. It has a good adaptability for a variety of Portland cement, ordinary Portland cement, slag Portland cement and mineral admixtures.

6, It has a good economy, particularly suitable for the commercial concrete.

Specifications

Items | Specification |

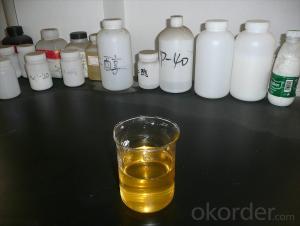

Visual Appearance | Orange yellow |

Solid Content(%) | 40.0±1.0 |

Density(23℃)(g/cm³) | 1.09±0.02 |

pH | 5~7 |

Chloride Content(%) | ≤ 0.02 |

Na2O+0.658K2O (%) | ≤ 2 |

The formaldehyde content (according to solid content exchanging) (%) | ≤ 0.02 |

The fluidity of cement paste(mm) | ≥ 250 |

Application

1, Adapt to a variety of industrial and civil construction, rail, water, marine,port, transportation, bridges, municipal, and electric power engineering andin-situ concrete, reinforced concrete, prestressed concrete and commercial concrete.

2, Adapt to different strength grades of concrete, especially suitable for the key projects of all kinds of high-performance concrete.

3, This product is particularly recommended for high strength and high durability concrete, the superfluid self-compacting concrete, pumping concrete, precast components, steel fiber and special concrete.

4, Composition with other polycarboxylate high performance water reducer at certain percentage, it is used in the place with higher requirement, such as commercial concrete, mean while saving costs.

The using method

1, This product recommended content is 0.25% -0.85% of the total weight of cementitious material, actually content should be experimentally determined.

2, Due to the adaptive differences between different types of the cement and admixtures, The adaptive test of cement and admixture should be done before using or changing the cement type.

3, In order to achieve better water-reducing effect, and ensure the quality of concrete, the mixing time is recommended at least 120 second before the concrete mixing test.

4, This product is sold as raw material, it shows good compatibility with a variety of retarders, defoamers, and air-entraining agent. Processing compound is not recommended to be used directly on the concrete and other materials. It is strongly recommended through trial and complex technology to determine the using method and conditions prior to use. It can be used as a masterbatch that mixed with different characteristics agent to produce retarded setting agent, early strength agent cryoprotective agent and pumping agent, it can fully meet the requirements of the different categories of engineering, construction technology, construction technique and temperature conditions.

Packaging, transport and storage

(1) It is packed in 1000Liter per IBC Tank, Other special package can also be available according to prior consultation.

(2) Special measures should be taken to ensure entire package. Keep waterproof during transportation.

(3) Dry and well ventilated warehouse is needed for storage. Quality guarantee of AM-200 is six months under normal conditions. If storage has surpassed the time, test must be done to confirm the validity.

Health and safety

(1) Once splashed into eyes and skin, wash immediately with plenty of water and seek medical treatment.

(2) Inedible. When eating by mistake, drink sufficient water to urge to vomiting, and then go to hospital.

(3) No littering. Caution should be taken to protect environment.

Customer services

Data in this manual is only for reference. Technical data about dosage and mix proportion is available if necessary. Professional services in site are also available. More information needed, please direct all inquiries to company.

- Q:fuelsome bottles say to use every 3000 miles, but then under it, it will say good to use after every fill up. Which one is it, for fuel injector cleaner?oilcan i use Marvel Mystery oil in between oil changes to top off a bit? Is this ok, or do I have to drain in soon like seafoam. Also if I overfill the oil, what will happen?thanks

- fuel. a lot of what the bottle says are advertising. Best advice is to use whatever you want, every oil change. you can use marvel mystery oil in the gas, I do this and have had fine results. Use 4oz per tank of gas. for oil, you can use marvel in the oil and can leave it in. I've used seafoam and have left in the oil long term, like 1000 miles, never have had an issue, with it. You really don't need to worry about oil additives as much, but whatever you do never use the flush stuff, it's kerosene and will cause more harm than good. as for overfilling, you can overfill 1 quart in most cases and be pretty much fine. Usually what can happen is the oil can begin to foam/aerate and the oil pump will pickup oil blended with air vs. straight oil.

- Q:I use gasohol in my car. Is it necessary to use gasoline additive, to keep the gas from freezing?

- You may have disagreeable minerals in your water that causes a reaction to the copper pipe. Instead of treating your water , replace the faulty copper with PEX piping . It is very easy for a DIY to use.

- Q:ok well, i already know what an additive inverse is, but i have to make a poster for math about it and i need a way how you can remember it

- Driftwood lowers PH of the water and Cichlids like a high or hard PH. Thats about the only reason I can think of.

- Q:is it true that every integer has an additive inverse?

- So Yes it is true. If x is the integer than -x is the additive inverse.

- Q:How can I find information on the oil additives and lubricant market in Venezuela? (size, value, etc)?

- I use PDV 20w50 for my SUV. I don't remember the exact price, but it ranges between 7000 and 14000Bs a liter. They also sell the 5 liter size, it costs less per liter, but I don't remember the price. How much is a Bs? There are two prices, because we can't exchange money freely. 2150Bs 1 USD (official price) 4000-4500Bs 1 USD (black market)

- Q:please verifyadditive inverse of 2/-92/9 whereas ifit is asked what is the additive inverse of 2/9 shouldn‘t we write the answer as -2/9how did the answer came????

- note that -(2/9) -2 / 9 2/-9 as long as there is just one negative, it doesn't matter where it is so the opposite of 2/9 can be written as either -(2/9) , -2 / 9, or 2 / -9 all the same number and yes, the opposite (additive inverse) of 2/ -9 is 2/9

- Q:I just purchased the car and i have been told different things. Some say low octane 87 or 89 and others said run 94 if you can.

- The best fuel to use for an older car like that is high grade. Use 94 octane, if you can get it. Also, every four (4) fill-ups, you should add lead additive. In 1969, there was no unleaded gas and these cars need to have lead added to them for the best performance. Trust me, if you use low grade, unleaded gas, you will start to experience problems within a few months. I have had some older machines (having grown up in the 60's and 70's) and they just don't build them like that today. By the way, congradulations on your new toy.

- Q:I need to know what it looks likeafter it is processed and ready to use and if it is ever snorted up the nose?

- Some you can, some you can't - have you read the instructions? Why not just add an extra blanket? We should all be trying to cut down our use of electricity.

- Q:can you put an additive in a premium only car when there is no premium available?

- it could be a lot of things .you might want to save your self some money and take it to a good transmission shop and have it done right

- Q:What are the disadvantages of food additives?

- I guess it all depends upon what you are calling additives. If you're talking about preservatives, I guess the bad part is that they take the excitement out of eating a slice of bread and then finding it has mold on it. As a kid, store bought bread would turn green in a week if not sooner. Now the stuff can be weeks old and still not be hairy. As far as additives causing cancer and all that stuff, that's a bunch of hooey. If they are FDA approved, they have undergone rigerous testing in the lab as well as in the market place. If they caused all the illnesses the one responder stated, the entire human race in developed counties would all be dead. And as for nutritional defeciencies?? That's what most food additives are, nutritional supplements. What countries in the world have the greatest vitamin and nutritional defeciencies? It's certainly not Europe, America, Japan, Australia and other developed countries where the food is laced withadditives", but rather undeveloped countries in Africa and Asia where locals depend mostly upon locally grown food. Check out historical instances of scurvey and vitamin D defeciencies in people living in the higher latitudes during their long winters. Supplementing milk with vitamin D has basically eradicated the latter, meaning score one for the additives. As far as allergies, some people are allergic to simple, unadulterated peanuts or milk. Those foods could unprocessed and have just come out of the ground or the cow and they'd still be allergic to them. And other individuals are allergic to bee stings, certain insect bites, plant pollens, animal hair or dander and so on, meaning that an allergic reaction has nothing to do withadditives" and everything to do with the individual person's genetic makeup or previous exposure to the allergin.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polycarboxylate Superplasticizer AM-200 for Concrete Admixture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords