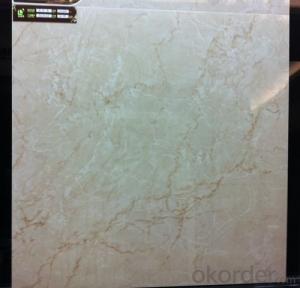

Polished Porcelain Tile Natural Stone Serie Color CMAXSB0632

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1382.4

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Key Specifications Polished Porcelain Tile Natural Stone Serie Color CMAXSB0632:

Product information:

Material: soluble salt porcelain

Various colors are available

Size: 600 x 600mm

Thickness: 10mm

Features: non-slip, wear- and water-resistant

Packing: 4 pieces/carton, 29.5kg/carton

20-foot container: 880 cartons

20-foot FCL container: 1267sqm

Carton with pallets or customized

Primary Competitive Advantages :

First choice,top grade.

Water absorption:<0.1%.< p="">

Delivery Time:15~25 days after deposit.

Certicate: CE,ISO9001,Soncap,etc.

Competitive price and good quality

Usage— Suitable for home, high grade office buildings, high-grade hotel, airport, shopping mall,

deluxe clubs floor and wall tiles etc.

This series of products in addition to good wear resistance with ultrafine tiles, flexural strength,

and low water absorption, the appearance of the product, due to be fired into a crystal frit, so

three-dimensional effectprominent, white the texture clear, natural, delicate harmony and balance without duplication, with impeccable decorative effect, close to natural stone.

Technical characteristics:

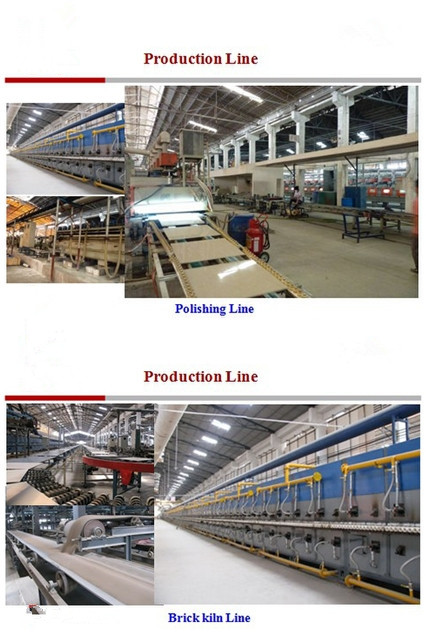

Adopt international advanced ceramic cloth exquisite processing technology, selected high

quality pure raw materials, on the product body, with moist and gorgeous color, microcomputer

total precision control, multiple temperature control forming technology create gorgeous texture

hd grain boundary, bottom dense embryo thicker, pure texture, deduces the natural stone material through the external environment and the geological characteristics and the dynamic form of change,

also make products with high hardness, high gloss, low water absorption, strong dirt resistance, easy

to clean, etc excellent characteristic

Main Export Markets:

Mid East/Africa

Central/South America

Asia

Australasia

Southeast Asia, Mideast Asia

Product Picture :

Production Line :

Product Certificates :

Packing Details :

FAQ

1. For Polished Porcelain Tile, is the 30*60 available?

—— Yes, 30*60 is available. Due to the basic size is 60*60, we need to cut 60*60 tile into 30*60. 6 pcs are packed into one carton.

2. What is the MOQ for this tile?

—— Normally the MOQ is 1382.4 m2 for one 20’ container. To support our clients, we could go with 3 models to fill one container at most.

3. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton or our Carton with our CMAX brand name. But for carton of client’s own design, the MOQ for one size is 5 containers, due to the carton factory can’t arrange production if quantity is below 5000 pcs.

- Q:I need to tile a kitchen back splash from counter to cabinets. Backerboard at the moment is drywall, textured and painted. I‘d like to hear some opinions on tiling directly over this or using cement backer board. Also thinset or mastic?

- Well, it depends on a few of things. If the drywall is really lumpy, I would use the cement board. If the area near the sink gets really wet, I would use the cement board. Honestly, I would try and smooth down the drywall before making the job any harder than it has to be. As for thin set vs. mastic, well I prefer mastic for thin small tiles because of the smaller notches and for wall work because I find there is less slippage, but they also say that mastic is not good to use in a wet area because it can mildew. Honestly if I were doing your job, I would leave the drywall and sand it down, (that is unless you are just talking about a normal light texture, then I would just leave it alone), use mastic and call it a day.

- Q:I have extra floor tiles that i had my kids paint and i want to put them together for my husband for fathers day. any ideas on how to do that?

- well you can put the tiles somewhere else? Maybe buy some more and make a cool tile medallion in your backyard or something? That seems to be pretty popular !

- Q:Suggestions and stories needed. We have 3 kids, 2 dogs (inside). I am on the fence. We bought stuff for doing the tile but now I am thinking laminate.

- Both are good choices. Tile is more durable but its cold in the winter and harder on the feet. Laminate has a warmer feel and the pad gives it a little bit softer feel. Plus glass objects don't always break when you dop them on it. But it can be damaged a lot easier than tile. I am not saying its easily damaged, by no means, its very durable and will with stand 3 kids and 2 dogs. Laminate is also not recommended in high moister areas. As far as maintaining the floors, Laminate is easier just wipe it up a few times a month and your good to go. Tile needs the grout to be sealed and needs to be scrubbed when t gets real dirty.

- Q:i going to tile my whole house both floors bath room and all with the same tile it is a 20x20 tile diagonally where should i start and does it really matter where ?

- Start doing the largest area and do a 1/2 tile on the out side wall. All interior walls are supposed to be layed out to the out side and be square. Now if you have a long visible hall way near by, you may want to split that to get a good look at it from there. Its hard to positively say with out seeing it. I could visualize it then. Since this is a diagonal you cant control to much where the tiles land. If it were a straight lay, you d have a bit more control as to the layout. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q:I hava a 12x12 ceramic tile that we want to hang on the wall (not permanently). The tile has no hooks or anything in it. What‘s the best way to hang it?

- Ceramic tile is a wonderfully versatile material. Not only does it make beautiful flooring and countertop surfaces, it can be crafted as a work of art in its own right. If the piece has a hanging wire or other hanging device, then hanging a ceramic tile wall piece is no different from hanging a picture. However, many ceramic tile artworks do not include any built-in hanging devices, and so it may be necessary to install one. 1. Lay the ceramic tile wall piece flat on a work surface. Place several pieces of cardboard underneath the tile. Clamp the tile to the work surface. 2. Determine two locations near the top corners of the piece for holes. They must be at least one inch from the edge of the tile and at least three inches from the top of the tile. 3. Cover the drilling locations with duct tape and mark the drilling points. 4. Install a carbide-tipped masonry bit into a variable-speed drill for drilling regular ceramic tile. For drilling porcelain, use a diamond-tipped drill bit. 5. Drill slowly into the tile. Apply very light pressure while drilling to avoid cracking the tile or its glazed surface. 6. Thread a hanging wire into the drilled holes. Twist the wire securely around itself behind the tile. 7. Hang the ceramic wall piece in the desired location from the hanging wire.

- Q:When tiling a counter top, do you need to remove the existing covering? I am assuming that I would. If so, should I apply the tile directly to the plywood? Will the plywood be wide enough?

- This is a litttle tricky to answer because I can't see what you have to work with. However, here is how I do it. Remove all of the old counter top down to where you can see down into the cabinets below. Then I use 3/4 inch thick plywood. It doesn't have to be the sanded kind because over the top of that I put a layer or the thin 1/4 inch tile backer board, sometimes called Miracle Board or Cement board. Be sure to counter sink the screw heads just below the serfice or you will have problems seating your tile. I always try to size my top at this point so I don't have to cut many tiles. Every situation is different so you have to do some figuring at this point. I always lay my tiles out dry to see how they fit first. Then you must think about the edge trim that will go around the outside edge of the counter top. I use oak but that also depends on what style you are doing but none the less something must incaplsulate the tiled area. Use the little tile spacers at the corners of the tiles to get an even fit. They are shaped like an + and are cheap. Most home centers have guides for free that have good info, take advantage of that. I wish I could send a picture of my island top. Just looking at a picture helps alot. Also, use the pre-mixed latex adhesive to put them down, much better and don't forget to seal the grout when it is dry. Good luck!

- Q:I believe the tiles were made in Mexico. They are light beige in color. They were installed in the master bathroom which has a shower stall, no bathtub.

- I tile every day of my life, and while not a major fan of sealers, I get it that many are, in the belief that they retard dirty and mold, etc. It will be a life long, occasional task however. It makes little difference where the tile was produced, what matters in your case is whether or not the tiles are glazed in the firing process. One would hope any contractor holding any level of intelligence would not install unglazed tile in a bath or kitchen. IF they are glazed, sealing is a useless procedure. There is no need to seal tile that has been glaze fired, essentially turning the surface into glass, NON porous. Certainly no matter what you seal, anywhere, the surface should be as clean as possible. Steven Wolf Just my two sense

- Q:Hello. The office we work in has what we believe to be vinyl tiles, 12x12, with a white powdery substance that is always on the floor. It looks as though the tile has never been sealed before so I‘m not sure if this is the cause. I have read online about efflorescence. Could this be that? I‘m really nervous because I don‘t know if it is asbestos. There are a few people in this area, and our chairs are constantly rolling around on the floor. I would say that the floor is just worn down because of the high traffic but I just wanted opinions on what it could be. This powder gets on the bottom of our chairs and our shoes. Any help is appreciated!

- Hi, I work in the building trade have had to do basic asbestos awarenesss training.Asbestos was used in floor tiles into the 1970's- But I strongly recommend you look on the Health Safety web site this will give you advice on were to go for help. If in ANY doubt you must check this out urgently, please don'tt put it off- asbestos kills.

- Q:What is the loss of tiles? What is the difference between floor tiles and bathroom tiles? Living room masonry 80X80 balcony, bathroom floor, kitchen floor is 30X30 bathroom wall, kitchen wall is 30X45. We help me see how much loss in this

- The state for the tile paving loss is not a serious requirement and description of the tile in the paving process, due to the construction level of workers, the degree of careful differences, the relevant size of the paving area, whether it is related to special flower shop , Eventually leading to its loss will be different. In general, in the tile purchase, according to the actual paving area plus 5-10% of the loss is appropriate.

- Q:i am looking for the best way to lay 600 x 600mm polished porcelain tiles on a caber chipboard floor can anyone help?

- Chipboard is not a suitable underlay for tile. Check the bag of mortar for acceptable substrates, at the very minimum you will need a tile backer. If there is any deflection in the chipboard I would recommend putting plywood down before using tile backer. Remember that tile backers don't add much strength as far as flexing is concerned, they are used so the underlayment has a similar expansion and contraction rate as the tile itself. Wood will not give you this and cracks will develop over time.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polished Porcelain Tile Natural Stone Serie Color CMAXSB0632

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1382.4

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords