Specifications

1.Plastic fitting.

2.Y type.

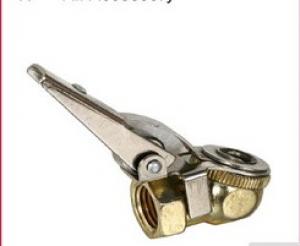

Features:

1.Brass with good nice nickel plated.

2.BSPT thread (British Standard Taper Pipe Thread).

3.Sleeve with black color.

4.Each and every pcs was tested at 10kgs/cm2.

5.Thread with teflon coating which can seal directly without any other seal material.

6.Bottom was hexagonal suitable for fitting by lkey.

7.Chipware is zinc.

8.Inner seal can bear 75 degree

9.The snap spring is stainless steel with heat treatment and the life time is more than 1000 times.