AIR FILTER BFC-4000 5”

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

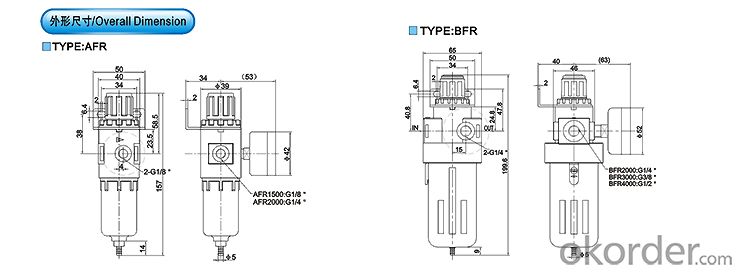

Type

small size

middle size

Joint pipe bore

1500:G1/8"

2000:G1/4"

3000:G3/8"

4000:G1/2"

Drian Type

Blank: Differential Drain

D: Automatic Drain

- Q:Acting as pneumatic component 60I've been selling pneumatic parts for three years

- If you are a regular dealer, you can consider doing it, but the funds settlement method should be discussed well.

- Q:What are the common pneumatic components?

- Cylinder, solenoid valve, air source processor, auxiliary component

- Q:Where are the industry standards for pneumatic components?

- 5, GB/T, 2350 - 1980 (1997) hydraulic, pneumatic systems and components, piston rod, thread type and dimension seriesEQV ISO 4395:19786, GB/T 2351 - 2005 hydraulic pneumatic system with hard tube outer diameter and hose inner diameterISO, 4397:1993, IDT7, GB/T, 3452.1--2005 hydraulic pneumatic O rubber sealing ring first parts: size series and toleranceISO, 3601-1:2002, MOD

- Q:What is a pneumatic major?

- To train technicians, hydraulic, pneumatic equipment installation, debugging, maintenance and other technical management work, and general mechanical, hydraulic and pneumatic system design ability of high-level technical application talents

- Q:What are the classifications of cylinders in pneumatic components?

- The cylinder is one of the most widely used pneumatic actuators in pneumatic systems. Depending on the conditions of use, the structural characteristics of different, the use of different functions, installation of different forms are classified as follows:

- Q:Pneumatic oil filter oil in what

- Oil mist cup lubricating oil level height can not exceed the total height of the 3/4 cup, oil: turbine oil No. 1 (International designation: ISO VG32), its properties are very thin viscosity of 7E degrees (the equivalent of lubricating oil, sewing machine oil 5E ~7E degrees); GB grade: 7 machine the lubricating oil (viscosity 7E degrees), sewing machine oil, is also more convenient choice.

- Q:What are the requirements of the pneumatic system for compressed air?

- Pneumatic components are not suitable for use with ultra dry air. Please use the ultra dry air type element. Ultra dry compressed air will shorten the service life of pneumatic components.Want to know more of the pneumatic components can go Wuxi smart look, oh well

- Q:I've checked PT teeth, NPT teeth and G teeth. I'd like to know which standard teeth we use on our cylinders, fast couplings and other components. Thank you

- The G is 55 degree tooth angle straight thread, and the NPT is 60 degree tooth angle, vertebral canal thread. What brands and cylinders do you use? What specifications do you want to see?.

- Q:What is the oil in the cylinder in the pneumatic original?

- Compressor oil from the air compressor is the most harmful substance to pneumatic components. It needs to be thoroughly removed by using an oil mist pre oil-water separator.

- Q:How to maintain the pneumatic components regularly?

- Monthly or quarterly maintenance work should be more careful than daily and weekly maintenance, but still limited to external inspection. The main contents are: carefully check everywhere leakage, loosening of the screws (including terminals) and pipe joints, check valve exhaust air quality, check the adjustment part of the flexibility, check the correctness of the instrument, the reliability of the check valve switch, check the SMC cylinder piston rod and the quality of content everything from the outside to check the.Want to know more about the cylinder, can see the Wuxi smart home is also good

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AIR FILTER BFC-4000 5”

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords