AIR FILTER BFR-2000 1/2

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

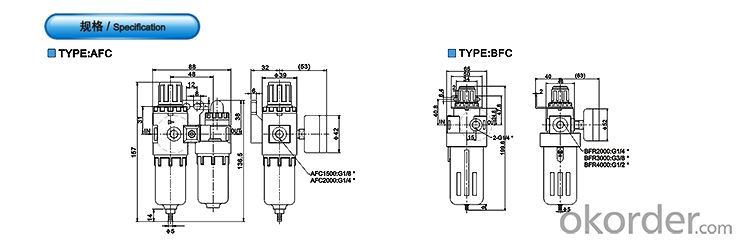

AFC\BFC Series

TYPE

small size

middle size

Joint pipe bore

1500:G1/8"

2000:G1/4"

3000:G3/8"

4000:G1/2"

Drian Type

Blank: Differential Drain

D: Automatic Drain

CERTIFICATE: ISO9001:2000 QEC CE

MAX PRESS: 9.9kg/c㎡

ADJ RANGE: 0.5-9.0kg/cm²

- Q:Acting as pneumatic component 60I've been selling pneumatic parts for three years

- If you are a regular dealer, you can consider doing it, but the funds settlement method should be discussed well.

- Q:What does the pneumatic component contain?I'm a beginner. What pneumatic parts do I have?

- Commonly used are cylinders, solenoid valves, pressure regulating valves, pneumatic motors, filters, couplings, oil and water separators, and so on,

- Q:What is a pneumatic major?

- To train technicians, hydraulic, pneumatic equipment installation, debugging, maintenance and other technical management work, and general mechanical, hydraulic and pneumatic system design ability of high-level technical application talents

- Q:What does pneumatic component mean?

- . The first step in learning pneumatic is to understand the pneumatic schematic diagram first. Schematic diagram is clear, and then combined with the actual understanding of pneumatic components, features.

- Q:What is the gas in the two pneumatic combination?

- Now most of the cylinder, valve generally in the pneumatic components of the pre sliding parts parts into the semi-solid grease like (or paste oil) called non oil components. Therefore, there is no need to provide oil mist lubrication in such pneumatic transmission. If the oil mist lubrication to non oil pneumatic components, not only has no meaning, and semi solid lubricating grease is very thin oil mist and oil slowly dilute the sealed gas loss is bad. If oil mist has been supplied, keep it up.

- Q:What is the difference between pneumatic components PC8-03 and PC8-02?

- Do you mean the connection? If it's the joint, 02 refers to PT1/4, and the 03 refers to the PT3/8, the joint is one side of the pipe and the thread, and the two are inserted into the 8 pipe

- Q:Will the gas in the gas path corrode the pneumatic components after passing through the oil sprayer?

- The operating principle is that the atomizing oil is lubricated with high pressure air to the pneumatic equipment, and is not corrosive. Although the pneumatic solenoid valve or cylinder is no need to add lubrication. But friction products increase the service life by adding lubricating oil.Gas atomizer does not recommend adding common quality oil. It is recommended to use turbine No. 1 atomizer special oil.

- Q:Pneumatic components, three bit, five - way, can you explain?

- Five way: solenoid valve has 5 vents (usually 1 gas supply port P, 2 use mouth A, B, 2 exhaust port EA, EB)Above! A mouthful, slowly look at yourself

- Q:What about leakage of pneumatic components?

- But as long as the cylinder is removable, there are basically standard sealing components can be replaced.

- Q:Pneumatic components of SMC pneumatic components

- The widespread use of oil-free lubrication technology, to meet some special requirements. Due to the environmental pollution and the requirements of electronic, medical, food and other industries, the oil is not allowed in the environment, so no oil lubrication is the development trend of pneumatic components, and no oil lubrication system can be simplified. The mist sprayer in European market is out of phase, and oil-free lubrication has been widely used. In addition, in order to meet some special requirements, deodorization, sterilization and precision filter are being developed. The filtration accuracy has reached 0.1~0.3 m, and the filtration efficiency has reached 99.9999%.In view of some special requirements, it is widely acknowledged that improving and developing pneumatic products can occupy a market and obtain small economic benefits. Ji'nan Huaneng pneumatic components company has developed the cylinder and valve for the special requirements of railway marshalling and wheel rail lubrication, which has attracted the attention of the railway sector. The use of new materials, combined with the new technology. The development of foreign film dryer, the dryer using reverse osmosis membrane filters technology to the compressed air in the water, energy saving, long service life, high reliability, small volume, light weight and other characteristics, is suitable for the flow of small occasions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AIR FILTER BFR-2000 1/2

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords