AIR FILTER AR-2000 1"

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

pressure control pneumatic componentSMC AR4000-04

best solution for automation . strict quality and cost control system !

free to adjust the pressure range ,reduce the impurity of air .oil and water seperator .

best solution for automation . strict quality and cost control system !

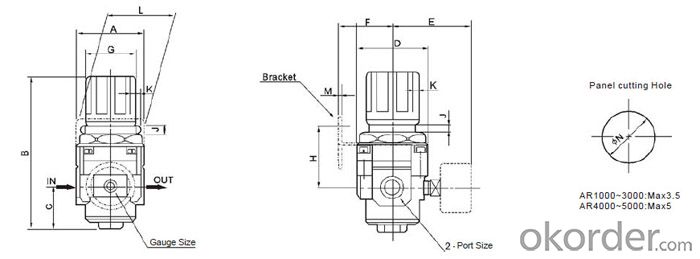

parameter diagram:

professional manufacturer of pneumatic ,best quality and severice for you !

- Q:It is a standard pneumatic drive element. What functions does it have on the cylinder?

- Engine power decline.Increase fuel consumption.Fault diagnosis and removal of cylinder wear

- Q:What are the main parameters of pneumatic components?

- There are many kinds of pneumatic components. In general, they can be divided into auxiliary components, control elements and actuating elements:Auxiliary components: filters, pressure reducing valves, oil mist, etc., the main parameters are the pipe diameter, flow size, filtering accuracyControl components: mainly electromagnetic valve, the main parameters are voltage, nozzle diameter, bit through function, installation method, flow, single coil or double coil, etc.Pneumatic actuator: the main parameters is the cylinder stroke, installation, installation size, positive reaction, etc.Basic parameters on these, special occasions special treatment

- Q:What does pneumatic component mean?

- . The first step in learning pneumatic is to understand the pneumatic schematic diagram first. Schematic diagram is clear, and then combined with the actual understanding of pneumatic components, features.

- Q:Pneumatic components cylinder generally guaranteed for several years

- Domestic basically in hundreds of kilometers, imports of basic in thousands of kilometers. Solenoid valve is also done by the number of times to do the warranty

- Q:To pneumatic three components refueling, I would like to ask pneumatic three components should use what lubricating oil?. Thank you

- The viscosity, composition requirements are relatively high. Generally recommended ISO VG32 turbine oil (commonly known as turbine oil). Fog and lubrication is the best.

- Q:Main points of type selection of pneumatic control valve

- Pneumatic control valve refers to the pneumatic system to control the flow of air pressure, flow and flow direction, and to ensure that pneumatic actuators or institutions work properly all kinds of pneumatic components. Pneumatic control valve structure can be broken down into the valve body (including the valve seat and valve hole, etc.) and valve heart two parts, according to the relative location of the two, there are normally closed and normally open two. Valve from the structure can be divided into: cut-off type, slide column and slide valve type three valves.

- Q:What is the oil in the cylinder in the pneumatic original?

- Compressor oil from the air compressor is the most harmful substance to pneumatic components. It needs to be thoroughly removed by using an oil mist pre oil-water separator.

- Q:Pneumatic components generally used in what industry?

- Such as cylinders, pneumatic motors, steam engines, etc.. Pneumatic components are a form of power transmission, as well as an energy conversion device that uses gas pressure to transmit energy.

- Q:Pneumatic components generally used in what industry? What type of machine?

- An element that works by force of pressure or expansion of a gas, the component that converts the elastic energy of a compressed air into kinetic energy. Such as cylinders, pneumatic motors, steam engines, etc.. Pneumatic components are a form of power transmission, as well as an energy conversion device that uses gas pressure to transmit energy.

- Q:Pneumatic components of SMC pneumatic components

- The widespread use of oil-free lubrication technology, to meet some special requirements. Due to the environmental pollution and the requirements of electronic, medical, food and other industries, the oil is not allowed in the environment, so no oil lubrication is the development trend of pneumatic components, and no oil lubrication system can be simplified. The mist sprayer in European market is out of phase, and oil-free lubrication has been widely used. In addition, in order to meet some special requirements, deodorization, sterilization and precision filter are being developed. The filtration accuracy has reached 0.1~0.3 m, and the filtration efficiency has reached 99.9999%.In view of some special requirements, it is widely acknowledged that improving and developing pneumatic products can occupy a market and obtain small economic benefits. Ji'nan Huaneng pneumatic components company has developed the cylinder and valve for the special requirements of railway marshalling and wheel rail lubrication, which has attracted the attention of the railway sector. The use of new materials, combined with the new technology. The development of foreign film dryer, the dryer using reverse osmosis membrane filters technology to the compressed air in the water, energy saving, long service life, high reliability, small volume, light weight and other characteristics, is suitable for the flow of small occasions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AIR FILTER AR-2000 1"

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords