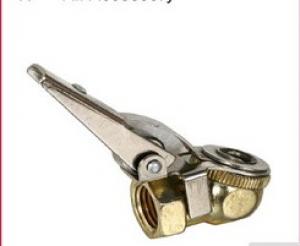

AIR FILTER BFC-4000 1/4

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Description:

· Air source treatment unit includes filter regulator and lubricator, It is in standard modular design and can freely separate and combine.

· Filter adopts novel vane design with high division efficiency and differential pressure discharge device. It can discharge water automatically.

· Regulator valve adopts balanced inlet structure with the advantages of stable pressure, high precision, and quick reaction.

· Lubricator is an element that can provide good lubrication for pneumatic system, with novel structure and easy adjustment of oil drip.

AIRTAC Air Filter Combination AFC2000 FR.L With Pressue Gauge

BFC2000 Two-point Combination Filter&Regulator Lubricator Air Units

BFC 3000 air combination filter regulator lubricator pressure regulator pneumatic component air unit air compressor

1/2'' BFC4000 Adjustable Pressure Air Source Treatment Unit

Air Source Treatment Air Filter Pneumatic Regulator Lubricator 0.5-9.0Kgf/cm2

- Q:Development prospect of pneumatic technology

- Through the adjustment of product structure and improvement of operation and management, China's pneumatic industry has maintained good economic performance since the late 1990s, and produced steady and sustained growth. Because of its advantages of energy saving, pollution-free, high efficiency, low cost, safety and reliability and simple structure, it is widely used in various machines and production lines. The expansion of application of pneumatic technology is the sign of pneumatic industry development. The application of pneumatic components mainly includes two aspects: maintenance and matching. In the past, the sales of domestic pneumatic components were used for maintenance, and in recent years, the sales share directly as the main supporting parts increased year by year. The use of domestic pneumatic components, from tens of thousands of dollars worth of metallurgical equipment to only 1~2 hundred yuan chair. Railway switches, locomotive wheel rail lubrication, train brake, street cleaning, hoisting equipment in special workshops, military command vehicles, etc., have been specially developed domestic pneumatic components. This shows that pneumatic technology has penetrated into all walks of life and is expanding.

- Q:What are the main parameters of pneumatic components?

- The parameters of each pneumatic component are different. Let me tell you something.1, filter: interface, flow2, solenoid valve: voltage, bit through3, the cylinder bore and stroke.Pneumatic components are basically the 3 blocks, the above are the main requirements, of course, there is one of the most basic requirements, that is, size

- Q:What does pneumatic component mean?

- . The first step in learning pneumatic is to understand the pneumatic schematic diagram first. Schematic diagram is clear, and then combined with the actual understanding of pneumatic components, features.

- Q:Pneumatic components cylinder generally guaranteed for several years

- Generally do not have a fixed time warranty, the cylinder is based on mileage mileage warranty,

- Q:I would like to ask you, pneumatic components, including what mechanical parts?

- Pneumatic actuating element (cylinder), control element (solenoid valve)

- Q:Which three pneumatic components are three?

- Finally, the oil mist is used to transfer the air containing the oil to the actuating element and to lubricate the actuating element.

- Q:What are pneumatic components?Pneumatic components include:

- Pneumatic components include: air treatment system components, pneumatic components (such as cylinder, pneumatic motor), pneumatic control components (such as pressure control valve, directional control valve, flow control valve, pneumatic logic element, pneumatic sensor), pneumatic auxiliary components (such as filter, oil mist for pipes, pipe joints, pipe etc.).

- Q:Introduction of SMC pneumatic components

- SMC pneumatic components over 11000 basic series, more than 610000 different specifications,

- Q:Can nitrogen be used as the source of air for pneumatic valves? Generally use compressed air as pneumatic components of the gas source, suddenly asked customers can use nitrogen

- Nitrogen can, of course, be more than 70 of the nitrogen in the air. Nitrogen is generally compressed air.

- Q:How does the pneumatic valve change the AC to direct current?

- Two. Comparison of pneumatic control valve and hydraulic valve(I) the energy used is differentPneumatic components and devices can use the air compressor station centralized gas supply method, according to the use requirements and control points to adjust the working pressure of each reducing valve. The hydraulic valve is provided with a return line to facilitate the collection of the hydraulic oil used by the tank. The pneumatic control valve can direct the compressed air to the atmosphere through the exhaust port.(two) the requirement of leakage is differentThe hydraulic valve is strict with the outward leakage, but a small leak inside the component is permissible. For pneumatic control valves, in addition to the clearance seal valve, in principle, does not allow internal leakage. The internal leakage of pneumatic valves causes the risk of accidents.For pneumatic pipes, a little leakage is allowed, and the leakage of the hydraulic pipe will cause pressure drop and pollution to the environment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AIR FILTER BFC-4000 1/4

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords