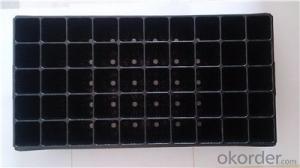

Nursery Plug Trays/Plant Seed Plastic Growing Trays Plug Tray

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of the seed tray: · Top quality and competitive price. · Variety design and good appearance. · Easy to use, and remove. · Durable and reusable. · Eco-Friendly.

Advantages: · Top quality and competitive price. · Variety design and good appearance. · Easy to use, and remove. · Durable and reusable. · Eco-Friendly.

Application: · Ideal for Starting seeds and Transplanting Seedling. · Suitable for both manual and automatic planting. · Suitable for Propagating Vegetables, Flowers and other plant from seed · in green-house or indoors.

Description Main Features of the seed tray: · Ideal for Starting seeds and Transplanting Seedling. · Suitable for both manual and automatic planting. · Suitable for Propagating Vegetables, Flowers and other plant from seed in green-house or indoors. Using time: · thickness of 0.5mm can be used 1 to 2 times. · thickness of 0.6mm can be used 3 to 4 times. · thickness of 0.7mm can be used 5 to 6 times. · thickness of 0.8mm can be used 7 to 8 times. · thickness of 0.9mm can be used 8 to 9 times. · thickness of 1.0mm can be used 8 to 10 times. Thickness vs. Weight: · Thickness of trays are from 0.5mm to 1.0mm. · 1.0mm: 155g±5g; 100pcs/ctn. · 0.9mm: 140g±5g; 120pcs/ctn. · 0.7mm: 110g±5g; 150pcs/ctn. · 0.6mm: 95g±5g; 180pcs/ctn. · 0.5mm: 80g±5g; 200pcs/ctn.

Seed Tray Specification: Materialps/pvcThickness0.5mm-1.5mm, standard:1mmWeight80g(±5)g-230g(±5)g, Standard weight:155g(±5)gSizelength:490mm-540mm, width:190mm-345mm,depth:25mm-150mm Standard:54mmX28mmCell count18-512Packagein cartonUsing time8-10 times

FAQ: Q:How Can I Get A Sample? A:You can get samples by communicate with our export sales. Q:How Long Is Delivery? A:Delivery time will be 7-25 days according to order quantity. Q:What Is The MOQ? A:Our MOQ is 1*20FT container quantity, allow to mix several items. Q:What Is Our Normal Payments Terms? A:Our normal payment terms now is T/T, L/C or Western Union,Papal. Q:How Do I Order Your Products? A:You can check our website for any items you interest and you can also get communication with our export sales and order for it accordingly. Q:What Kinds Of Material We Use In Our Product? A:Our plastic flower pots use material such as PP polymer or PE polymer.

|

- Q:Can agricultural plastic be used for hydroponic nutrient delivery?

- Yes, agricultural plastic can be used for hydroponic nutrient delivery. Agricultural plastic materials, such as PVC pipes or trays, can be adapted or designed specifically for hydroponic systems to deliver nutrients to the plants' roots. These plastic materials are often durable, resistant to water, and can be easily cleaned, making them suitable for use in hydroponic setups.

- Q:What are the different types of plastic products used in agriculture?

- Some examples of plastic products used in agriculture include plastic mulch films, irrigation pipes, plant pots, greenhouse coverings, and agricultural nets.

- Q:Can ground cover be used as a natural pest deterrent?

- Yes, ground cover can be used as a natural pest deterrent. Ground cover plants such as marigold, pennyroyal, and mint release strong scents that repel pests like mosquitoes, ants, and aphids. Additionally, ground cover can create a physical barrier that prevents pests from reaching crops or other vulnerable plants.

- Q:How are plastic nursery pots used in agriculture?

- Plastic nursery pots are commonly used in agriculture for starting and growing plants. These pots provide a convenient and cost-effective solution for propagating various crops such as flowers, vegetables, and trees. They offer a controlled environment for the plant's initial growth stage, allowing for better root development and protection from harsh weather conditions. Plastic nursery pots also facilitate easy transportation and transplanting, as they are lightweight and durable. Overall, these pots play a vital role in enhancing the efficiency and success of agricultural practices.

- Q:What is the purpose of agricultural plastic products?

- The purpose of agricultural plastic products is to provide practical and efficient solutions for various farming needs such as crop protection, greenhouse cultivation, irrigation systems, and packaging, ultimately enhancing productivity and reducing environmental impact.

- Q:we have a gold fish and we're transferring it to a plastic aquarium that was originally a hamster tank/aquarium. Will the the fish be ok? Does the plastic harm it?

- The plastic will not harm your fish however, the lack of space will. Goldfish are very dirty fish and need 2 gals of water per inch of fish. Sence goldfish get 10~12 inches fairly quickly they will not live long in a little hamster cage. They need at least 20~25 gals of water for each fish to be the most healthy and live the 20 to 30 year life span that can be expected of a well cared for golfish. good luck :~)

- Q:What are some ground cover options for wet areas?

- Some ground cover options for wet areas include moss, ferns, lily of the valley, creeping jenny, and sweet woodruff.

- Q:How do you choose ground cover that tolerates acidic soil?

- When choosing ground cover that tolerates acidic soil, it is important to consider several factors. Firstly, research and identify plants that thrive in acidic soil conditions. Acid-loving plants such as rhododendrons, azaleas, blueberries, and ferns are good options. Additionally, consult with local nurseries or horticultural experts who can provide specific recommendations for your region. It is also crucial to test the soil's pH level to ensure it falls within the acidic range. Regularly monitoring and amending the soil with organic matter such as compost or peat moss can help maintain the desired acidity.

- Q:Can ground cover be used to create a butterfly garden?

- Yes, ground cover can be used to create a butterfly garden. Ground covers like clover, thyme, sedum, or low-growing flowering plants provide food and shelter for butterflies. They also help retain moisture in the soil, control weeds, and add aesthetic appeal to the garden. Choosing native species and incorporating a variety of plants with different blooming periods can attract a greater diversity of butterflies and enhance the overall butterfly garden experience.

- Q:Or other plastic items?

- At times yes. but you can only recycle a plastic bottle no more than once. then they just even make more plastic which is harmful.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Nursery Plug Trays/Plant Seed Plastic Growing Trays Plug Tray

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords