MPET Two-Layer Fire Retardent Bubble Foam Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

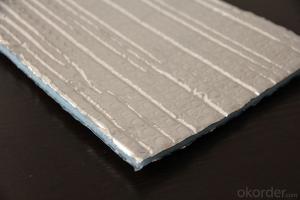

1. MPET Two-Layer Fire Retardent Bubble Foam Insulation Description:

Reflective insulation material consists of one or two layers bubble or foam that are sandwiched between layers of 99.9% pure aluminum radiant barrier foil . This style can be used in a variety of applications because of its thin, lightweight properties. The bubble layers creates Maximum R value and Vapor barrier , the reflective foil on both sides allow it to reflect 97% of radiant heat away from a structure on the outside and back into a structure from the insides. This is why it works effectively in both hot and cold climates

2.Main Features of the MPET Two-Layer Fire Retardent Bubble Foam Insulation:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

3. MPET Two-Layer Fire Retardent Bubble Foam Insulation Images:

4. MPET Two-Layer Fire Retardent Bubble Foam Insulation Specification:

PROPERTIES Test Data

Thinkness 3.5MM

Weight 256G/M2

Emissivity 0.03-0.04COEF.

Thermal conductivity 0.034W/MO

Apparent Density 120KG/M3

Reflectivity 96-97%

Water Vapour Transmission 0.013G/M2KPA

Corrosion Doesn't generate

Tensile strenght(MD) 16.98Mpa

Tensile strenght(TD) 16.5Mpa

AL+bubble +AL

AL +bubble /bubble +AL

AL+Bubble+ Foam+Bubble+AL

AL+Bubble+PE

AL+EPE +BUBBLE+AL

AL+XPE+Bubble +AL

Note : AL refer to Aluminum Foil,the structure and the surface color of AL can be changed as customer’s requirement

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of Fire Retandent AL Bubble Foam Insulation and is one of the large-scale professional investment Fire Retandent AL Bubble Foam Insulation bases in China. Annually more than 1000 containers of Fire Retandent AL Bubble Foam Insulation are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:Are rubber and plastic thermal insulation material and glass wool in air conditioner energy-saving materials ?

- They almost are.

- Q:What is the price of glass wool felt ?

- Hope you can provide the thickness and unit weight of the roll mat you need. Different unit weight, different price. Now the price is between 3300-3500 yuan and are increasing.

- Q:What is the difference between the glass fiber and glass wool?

- Fiberglass is an excellent inorganic non-metallic material. There are many kinds of glass fibers whose advantages are good insulation, heat resistance, corrosion resistance, high mechanical strength, and the drawbacks are brittle and poor wear resistance. Glass wool, a man-made inorganic fiber, belongs to a kind of glass fiber. It is a spongiform material made through fibration of melten glass. It is an inorganic fiber whose chemical components belong to glass, having good formability, low bulk density, low thermal conductivity, good thermal insulation and sound absorption, corrosion resistance and chemical stability.

- Q:How can I fix the glass cotton insulation board to the wall?

- The method to fix rock wool insulation boards to the wall: Use adhesion agents to bond rock wool and base wall together, and drive insulation supporting pins. Rock wool external thermal insulation uses rock wool board as insulation layer, and set it outside of the structure layer of external wall to achieve thermal insulation effect of wall. This construction method of composite wall insulation material requirements attached to the solid layer structure. The protective layer outside of insulating layer should have a certain intensity, impact resistance, crack resistance and waterproofness, and have good hotel decoration design. Common characteristics of rock wool wall system incluede the increase of thermal insulation properties of external wall, saving energy consumed for heating, the improvement of wall thermal inertia, and of indoor thermal environment. Compared with other energy-saving wall systems, rock wool system is conducive to the discharge of water vapor inside the wall, generating less internal condensation and dewfall, and the structural layer is drier and warmer. Also, the cost of rock wool system is cheap, it has good fire performance, sound insulation performance.

- Q:Rock wool board and glass?wool?board, which is more harmful to human body?

- Rock wool board, rock wool board has more layers!

- Q:What are the industry standards of glass wool and its products?

- Standard: Glass wool belongs to glass fibers and it is a man-made inorganic fibers. Glass wool is made through fibrosis of melten glass and form a cotton-like material. Its chemical composition belongs to glass, and it is a inorganic fiber which has good shape, small volume density, low thermal conductivity coefficient, thermal insulation, good sound-absorbing property, corrosion resistance and chemical stability. So the standard is relatively simple.

- Q:What are the differences between the common and high temperature resistant glass wool boards?

- The operating temperatures are different. The common boards can resist 300 degrees, the high temperature resistant one can resist 500 degrees.

- Q:The main classification and difference of glass wool

- And then by the temperature curing furnace, complete the curing process, product stereotypes, after cutting through the stereotypes will become a predetermined product, and then packaging.

- Q:Is the centrifugal glass wool board suitable for home use?

- Glass wool board is strictly tested by the state, and only through the ability to sell this material, you can use, rest assured

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

MPET Two-Layer Fire Retardent Bubble Foam Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords