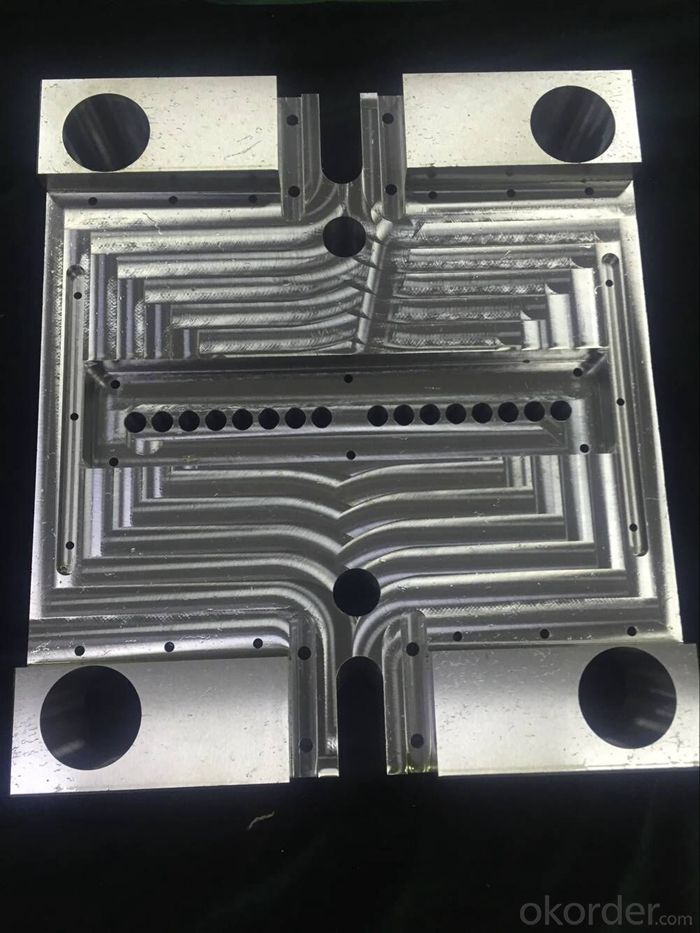

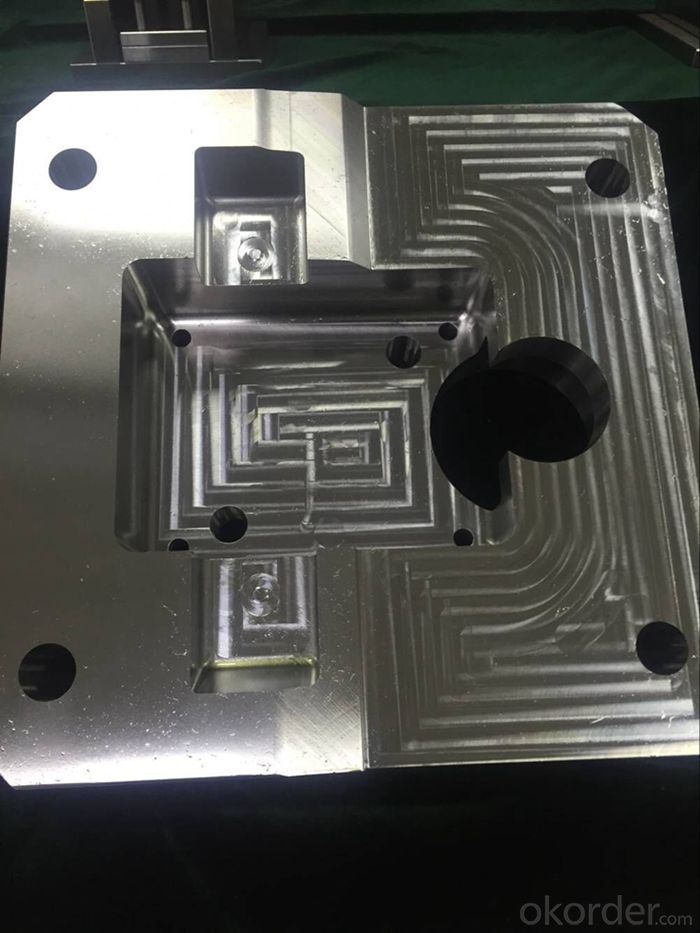

Mould Base for Plastic Injection Moulding Factory

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Our company specializes in manufacturing all kinds of plastic standard and non-standard mold, die-casting mould, stamping mould and all kinds of Euro HASCO mould frame.

The accessories are all made of standard guide pillar & bushes.

Thickness tolerance are processed according to requirements of 0.00 to 0.02.

High surface finish and roughness of standard.

Various types of formwork could be processed according to figure.

- Q:What is the difference between mould injection and blow molding?

- The process of injection molding and blow molding is different. Injection molding is the injection + pressure; The blow molding must have the head of the pipe, and the injection molding must have a gate section

- Q:How can silicone and glass steel molds be glued together

- As for the durability aspect is equal, it is easier to lose the texture of the silicon rubber mould. So if wandering between the building Lord, I suggest you according to the requirement of the customer, if the quality of high precision requirements of the customer requirements, so you must use silicon mold, on the other hand can also try using glass fiber reinforced plastic mould making low-end products.

- Q:What is the main meaning of die mold?

- It is the fractal type, which is to divide the mold into the upper and lower, the block, the living block. That is to say that the product is split into a cavity to make the mold.

- Q:What are the career prospects of the mould profession

- Mold professional prospect is good, although in recent years many learn this, but the market is only lack of talent, to shine on you, to learn, this is a good iron rice bowl, is willing to endure hardship, I also learn the mould... Oh, we have time to communicate

- Q:What are the five systems of plastic mould?

- Top out system, cooling system, exhaust system, casting system, molding system.Top out system, cool but system, molding system, casting system. All I know is that the four systems have not heard of five in the department.

- Q:The plastic mould automatically dies and the product drops when it falls

- You can't use the manipulator, the transmission belt is not even more. It's not possible to have a secondary top out, it's a problem that comes out of the top, and you've already written it yourself. A little want to buy something not give money, ha ha. Or semi-automatic. Use hand. Or you can try. Put slope slide board is a bit at the bottom of the mould, manipulate are placed at the side and operation side. When fall apart to make more hole products. Slide plate as close to the mold below (should consider a safe distance) to reduce product drop height.

- Q:What kind of mold do you have?

- The mold is known as the mother of industry and the variety is very complex. The type of mould used is stamping die/injection mold/casting mould. Three types of molds are different.

- Q:What are the advantages of using a hot runner?

- Advantages: hot flow channel, every parting can not emerge, pouring system along with the product is beneficial to automation production, save raw materials, can also reduce product time;

- Q:The wall thickness of the die is affected by the plastic parts

- Different plastic minimum wall thickness is different, small yu this wall, even if the uniformity also cannot be done The thin wall is difficult for the top, the layout of the thimble, the big and big.

- Q:Is the stainless steel bowl replaceable in the oven?

- Normal stainless steel 4xx series chromium and 3xx chromium-nickel stainless steel in the oven temperature (250) the stability of materialization must be free of problem

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mould Base for Plastic Injection Moulding Factory

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords