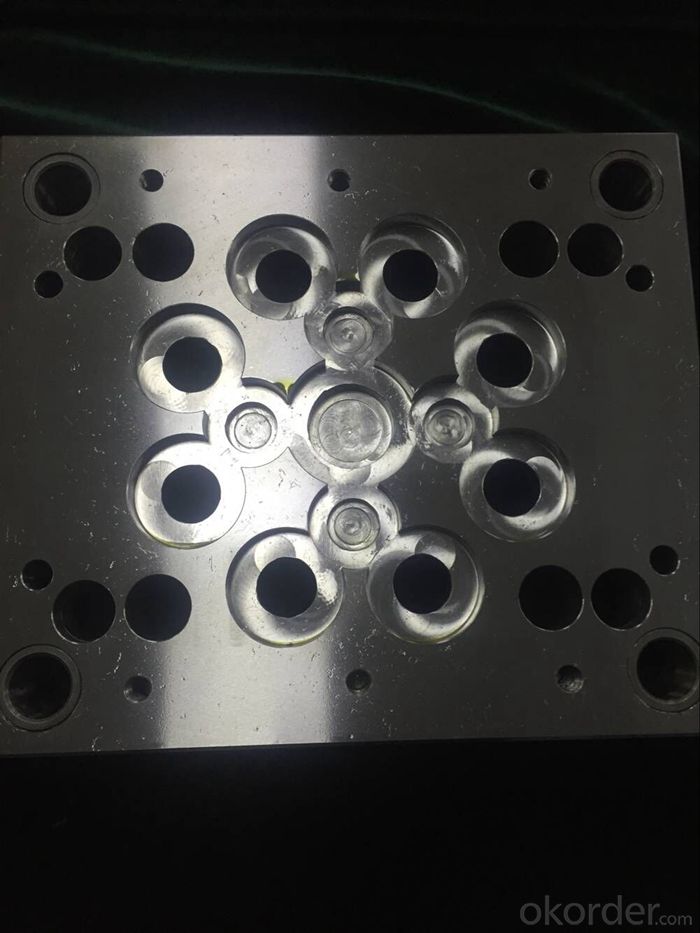

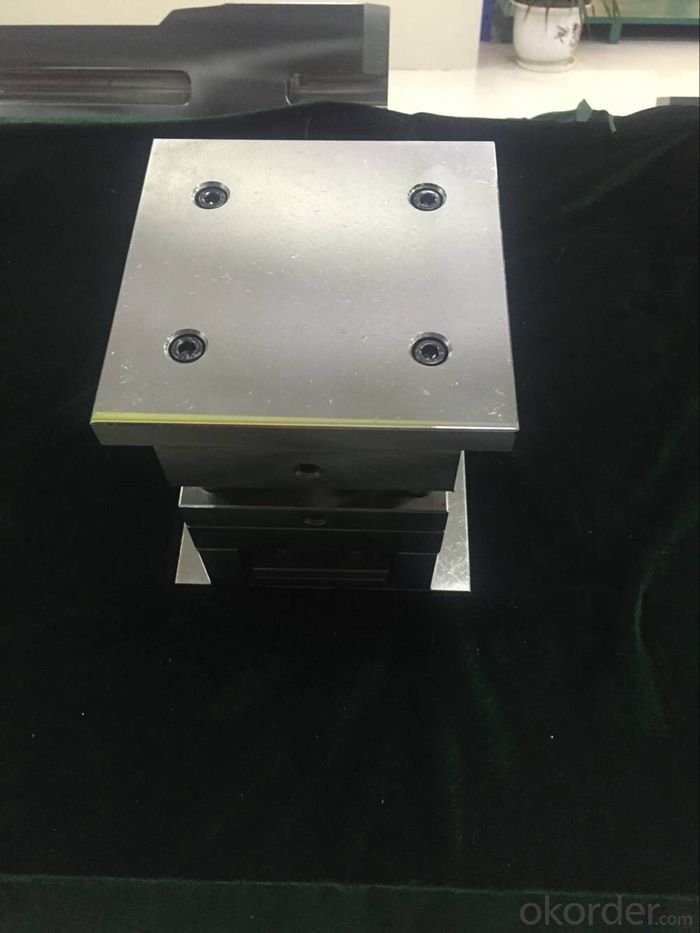

Stamping Mould Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Our company specializes in manufacturing all kinds of plastic standard and non-standard mold, die-casting mould, stamping mould and all kinds of Euro HASCO mould frame.

The accessories are all made of standard guide pillar & bushes.

Thickness tolerance are processed according to requirements of 0.00 to 0.02.

High surface finish and roughness of standard.

Various types of formwork could be processed according to figure.

- Q:What is the difference between the electric casting mould and the CNC working mould

- CNC handicraft processing and die processing are not very different from the processing method, it is the processing medium, the fine carving, the numerical control car and some nc processing equipment. It's very different from being processed. Hand processing mainly processing polymer materials, such as PC, ABS plastic and nylon, and so on, take the massive material carving milling polished lacquer after forming, the final products are generally full scale model of customer research and development, do good as future product identical in appearance. The purpose is self-evident, it is for the product to have a visual confirmation of the shape, color and match of the product before the model, reduce the risk of open mode.

- Q:The core is the moving or the model, male or female?

- In general, most of the mold core is dynamic model (male), cavity is fixed mold cavities (), but a small part of the mould, called inversion model, the product is no nozzle design, mold core is fixed mold (die), cavity is dynamic model (button).

- Q:What does it mean to pull the mold? What's going on?

- The injection mold is in the process of die, the product is caused by sticking to the side of the mother mold, which is called the former mold.

- Q:How do you handle the die holder

- Mold clamp mouth usually refers to the Parting surface, Parting line or the Parting line), including the slider, inserts, lifter and so on between the two in the products with line. Note: CNC processing aspect: parting surface machining with rubber products, at the same time to the mold clamp mouth do protection processing, die fillet directly in the machining process can be avoided; To remove the electrode: the separation of the Angle electrode and the electrode of the product is removed and the Angle of the die is avoided in the EDM process. Mold, industrial production to be used for injection molding, blow molding, extrusion, die-casting or forging, metallurgy, stamping, etc., to get the various mold and tools of the desired product. In short, the mold is a tool for molding objects, which are made up of various parts, and different parts are made of different parts. It mainly USES the physical state of the forming material to realize the processing of the physical appearance. There is the title of "mother of industry"

- Q:How to calculate the weight of die steel?

- The proportion of some steel is: industrial pure iron 7.87; Cast steel is 7.8; Steel 7.85; Cast steel is 7.8; Low carbon steel (carbon 0.1) 7.85; Medium carbon steel (containing 0.4%) 7.82; High carbon steel (1 percent carbon) 7.81 is: gram/square centimeter assumes you are the average steel that is "7.85 gram/square centimeter".

- Q:What is the pull mold

- The drawing die is also called drawing die, which is used to pull metal plates deep into cups or curved parts. For example, small metal cups or large car body shapes.

- Q:What is the mold for?

- Second, even if meets the difficult opportunity, most manufacturer can search im oligonucleotides du, put hundreds of thousands IN search of foreign original image, and then to design, the mechanical structure, might be some to improve and perfect, into a mold products with Chinese characteristics, can even exports to those countries, but IN the end it is hard to real marked "MADE IN CHINA" brand, and foreign figure, CHINA's steel, spell together hearts do not panic, ha ha So our mould industry, whether from the design research and development or mechanical processing, there is a lack of originality and independent technology of birth defects, congenital advantage is likely to be the only ancestor "cast ding forging sword" superb craftsmanship of the evolution of current die locksmith top workmanship, die locksmith world pageant held in that day, the voice of our athletes won may even more than the call for Chen to step down, opening with me, I must win!

- Q:Do machine parts need to be moulds?

- Not all of them have to be moulds. Look at your parts.I hope my answer will help you

- Q:What is the difference between imported mold and domestic steel

- One, the biggest difference is the price of imported materials is high, commonly in domestic material more than double. Second, steelmaking technology perspective, foreign well-known steel material generally purity of molten steel is higher, P, S, and five element content is low, low gas content, is simply less impurity. From the forging point of view, the imported mould steel is generally good, the forging pressure is bigger than the big, simply it is the uniform and transparent of forging. Four terms, heat treatment, the overseas research and development efforts, compare the commonly used die steel are basically developed abroad, so the heat treatment craft is advanced, and the equipment is advanced.

- Q:Why are the stamping molds wrinkling?

- The pressure side is too small, the clearance is too big, the die plane is not good. There are only a few of these

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stamping Mould Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords