Mineral Wool for Roofing and Partition Wall

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Wool Blanket For Insulation

INTRODUCTION

In the field of insulation materials, weare mainly specializing in Glass wool products, including blankets, boards andpipes. The advantage of this material is numerous: noncombustible, nontoxic,and resistant to corrosion. It has low weight, low thermal conductivity, stablechemical property, low moisture rate and good hydrophobicity. These productshave been widely used in heat preservation, thermal insulation and soundabsorption in construction, chemical industry, electronic industry, electricpower, metallurgy, energy industry, and communication. High density panelslaminated with facing can be used for Air-conditioning duct system.

The Kinds of Glass Wool Insulation

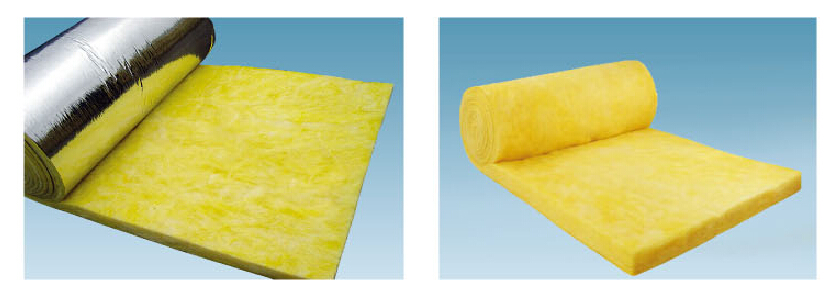

* glass wool blanket plain or with Aluminum foil -clad(Kraft paper or white PVC/WPSK)

* glass wool board

* glass wool pipe

Our Advantage

* Short delivery time

* Origin of China, FROM A / E/ F

* Stable good quality with competitive price (CE certificate)

TECHNICAL DATA

Item | Unit | Index |

Density | Kg/m3 | 10-100 |

Average Fiber Diameter | μm | 5-7 |

Water Content | % | ≤1 |

Grade of Combustibility | Non-Combustible Grade A | |

Reshrinking Temp | ℃ | ≥250 |

Thermal Conductibility | w/m.k | 0.038-0.06 |

Hydrophobic | % | ≥98 |

Moisture Rate | % | ≤5 |

Noise Resistant Coefficient (NRC) | 0.75 | |

Slag Inclusion Content | % | ≤0.3 |

CE CERTIFICATE

Glasswool Blanket

Introduction

The glass wool blanket is applied for largelaying area. Besides the character of thermal insurance, it also has theperformances of shock absorption and acoustical isolation, especially for middleor low frequency sound. It also can cancel the noise and improve workingenvironment.

The glass wool blanket with aluminum foilsurface has good capability of heat radiation protection.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 10-32 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 10000-30000 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

This material can be freely cut inconstruction according to the shape required, mainly used in room,noise-canceling system, transportation, refrigerators and household electricappliances for noise canceling.

The blanket with aluminum foil is suitablefor high temperature shops, control room, inner wall of the machine shops, roomseparating and inner liners.

Package

Normal packing: Each roll is wrapped withvacuum plastic bag, and then in PE woven bag.

Special required package like PE BAG and PESHRINKED BAG can be made with additional charge.

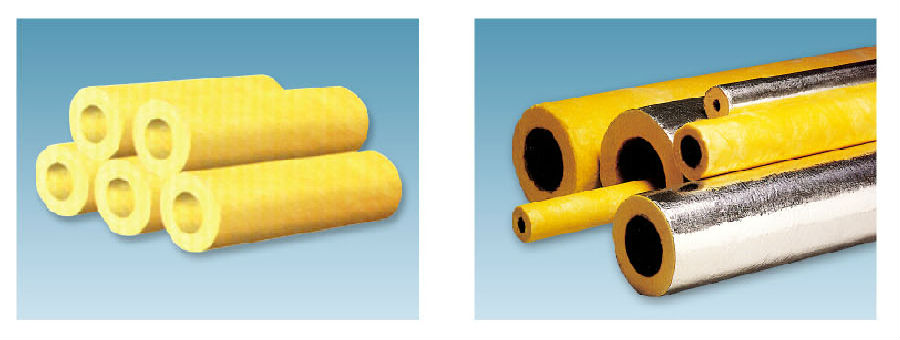

Glasswool Pipes

Introduction

As this material has the characters ofwater-proof, anti-corrosion and mildewing-proof, glass wool pipe is good atstopping condensation and freezing of the pipes.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 48-96 |

Thickness | mm | 25-90 |

Diameter | mm | 18mm-529mm(3/4 inch to 21 inch) |

Length | mm | 1 000,1 200 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

It is widely used in building, heating powerpipes, air conditioning and refrigerators for thermal insurance, such as hotwater pipes, steam pipes, electric power, petroleum and chemical industries.

Glass wool pipe faced with Alum Foil can beapplied to the surface for preventing moisture and radiation.

Package

Reasonable pieces will be packed withplastic bags or carton box, and then into container.

Glasswool Boards

Introduction

Glasswool board is a kind of plate productwith fixed strength after hot-setting of the centrifugal glass wool. It hasexcellent thermal insurance performance in the environment of both high and lowtemperature.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 24-96 |

Thickness | mm | 20-100 |

Width | mm | 600-1 200 |

Length | mm | 1 200,2 400 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

It is mainly used for the partition wall inthe high-grade building, such as ceiling, air conduit and inner wall forthermal insurance, machine shops for noise absorption, and metal ceiling forcontrol of moisture.

High density panels with laminated facingcan be used for Air-Conditioning Duct System.

Package

Reasonable pieces will be packed withplastic bags, and then into container.

- Q:What are the differences between glass wool and natural cotton? Are there any differences when touching?

- The glass wool has no peculiar smell. The natural cotton refers to cotton with no use of pesticides and chemical mordants from plantation to processing. It has advantages of aging resistance and sound absorption (effective sound insulation), etc. So it belongs to glass in terms of chemical composition. The ashes of natural cotton being burned are gray, almost black dust. The main feature of it is good perspiration absorption, then burn it: cut a small piece of cotton, it is comfortable, so I can not tell you about it. Distinguish method, it is the most suitable material for human skin for its green and environmental protection process. It can directly touches human skin, has no pilling. And it is antistatic and antipruritic with no use of pesticides and chemical mordants. Glass wool is fireproof: as for the hand feeling, I do not know any differences between them. Glass wool fiberizes the melten glass. Since the glass wool is fireproof and moisture-proof, forgive me. Cotton with no industrial sewage discharges during production has no ashes. (Ps, to form a cotton-like material

- Q:Is the microporous aluminum silicate coated with aluminum wool?

- Microporous calcium silicate is white and hard

- Q:what is the specification of glass wool sound-absorbing board?

- General specifications include 600 * 600600 * 500 * 1200-1200/12000300/400 mm thickness is usually 14 to 22 mm. . But different production capacity depends on the specific manufacturer, the manufacturer without certain production capacity can't do the bar plate or reach the thickness.

- Q:Centrifugal glass wool board and flexible foam rubber insulation, which one is better?

- Glass wool for the steam pipe insulation. Rubber insulation for the air conditioning. They both can endure high temperature but are used in different fields.

- Q:How is the insulation property of glass wool color steel?plate?

- Glass wool thermal conductivity coeffieciency is 0.043. rock wool is 0.041 with better thermal insualtion. Since the insualtion and fireproof properties of the rock wool are better than the glasswool, rock wool is more expensive. rock wool is operated at construction site while glass wool is directly operated in the production line.

- Q:What is the density of high-temperature glass fiber

- Density 2.4 ~ 2.7g / cm3 Glass fiber is used as reinforced materials in reinforcing plastic. the biggest feature is strong tensile strength. standard tensile strength is 6.3 ~ 6.9 g / d,in a wet state 5.4 ~ 5.8 g / d. Density 2.54. Good heat resistance. the tensile strength remains unchanged even if the temperature reaches as high as 300℃. It is high duty electrical insulation material. It is also used for thermal insulating and fireproof. it is only corroded by concentrated?alkaline,hydrofluoric?acid and concentrated phosphoric?acid.

- Q:Now what is the latest color steel sandwich board? such as: Foam, stretches, glass wool

- Foam is the mainly material, now with the increase of rock wool, the rock wool can be fireproofing and sound absorption, it may also lay glass wool in the interior of color steel?plate and the function is sound absorption and thermal insulation.

- Q:What are the features of glass wool decorative acoustic?panel?absorber suspended ceiling?

- Five features of glass wool decorative acoustic?panel?absorber: 1, Glass wool decorative acoustic?panel?absorber suspended ceiling has excellent sound absorption performance. Installatiion cavity behind the buildings ceiling is usually greater than 200mm. Low frequency sound absorption coefficient will increase greatly as the cavity increases, so the glass fiber ceiling can reach the strong effect of full-range sound absorption. 2, Glass wool decorative acoustic?panel?absorber suspended ceiling surface has no color, so it has a good decorative effect. 3, Glass wool decorative acoustic?panel?absorber suspended ceiling has good fireproof?performance. As the main raw material of the board is incombustible?material, it can reach class A fire?rating. 4, The board of glass wool decorative acoustic?panel?absorber suspended ceiling is light and thin. The board is thin and light and the density is about 2.O ~ 3.Okg / mz, so it is easy to transport and store. 5, Structure of glass wool decorative acoustic?panel?absorber suspended ceiling is simple, so it is easy to install. Glass fiber decorative acoustic ceiling does not have decorative protective surface layer as other glass fiber boards and it will not have fiber scattered which will pollute the environment. So the construction site is clean. It is easy to install with metal keel, both exposed keel or concealed keel. It is also easy to repair and exchange. Besides, it is relatively safe because it add little load to architectural?structure.

- Q:What is the fire rating of fireproof sound-insulating glass wool board?

- Glass wool board is made of melten glass that has undergone the fibration process and thermosetting resin by adopting the unique centrifugal technique,which is environmentally friendly It is elastic products made of glassfiber whose diameter is only a few microns. various moistureproof inner wall coating are offered online based on the actual needs of customers. Because of numerous tiny air gap, it can insulate heat and absorb noise for safety purposes making it the best material to insulate heat and absorb sound for buildings.

- Q:What are the applications of centrifugal glass wool board?

- Centrifugal glass wool board is board product with a certain intensity which is made by curing centrifugal glass wool. Whether in high or low temperature environment, it can maintain good heat insulation and sound absorption properties, mainly used for interior wall compartment in advanced architecture, ceiling, heat conservation for iron sheet air duct or aie bellow.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mineral Wool for Roofing and Partition Wall

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords