Light Weight PVC PU Conveyor Belt Wood Application

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Light Weight PVC PU Conveyor Belt Wood Application

Description of PVC Conveyor Belt:

The wood processing belt that CNBM produce have the characterics of low elongation, pending, low nise, stable size, durable, wear-resisting.This kind of belt are used different material, decorative pattern and high strength of the fabric to increase stability and strength.Products can be widely used in plywood, fiberboard, composite board production line and all kinds of woodworking machinery equipment.

With advanced technology and equipments, we could offer an extensive line of light weight conveyor belting, now our belts are widely used in airports, postal automation, parcel handling, treadmills, packaging and wrapping, confectionery industry, food processing industry, paper printing industry and so on..

Feature of PVC Conveyor Belt:

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Working temperature ranges from -10 to 80Deg.C

| code | Top cover | Bottom Cover | Thick | Characteristics | Fabrics | ||||

| Material | Colour | Surface | Material | Colour | Surface | mm | Plies | ||

| PVC conveyor belt | |||||||||

1/10 S/P W | PVC | White | Smooth | - | Natural | Fabric | 1.0 | Antistatic | 1 |

1/12 S/S BK | PVC | Black | Smooth | PVC | Black | Smooth | 1.2 | 1 | |

1/16 D/STF BK TM | PVC | Black | Diamond | - | Natural | Strong Fabric | 1.6 | Tread mill | 1 |

2/12 P/P W | Fabric | Natural | Fabric | Fabric | Natural | Fabric | 1.2 | Antistatic | 2 |

2/18 P/P W | Fabric | White | Fabric | - | Natural | Fabric | 1.8 | Antistatic | 2 |

2/20 D/P AG | PVC | Apple Green | Diamond | - | Natural | Fabric | 2.0 | Antistatic | 2 |

2/2O S/P AG | PVC | Apple Green | Smooth | - | Natural | Fabric | 2.0 | Antistatic | 2 |

2/20 S/P PG | PVC | Petrol Green | Smooth | - | Natural | Fabric | 2.0 | No-antistic | 2 |

2/20 M/P BK | PVC | Black | Matt | - | Natural | Fabric | 2.0 | Antistatic | 2 |

2/20 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 2.0 | FDA | 2 |

2/20 S/P W | PVC | White | Smooth | - | Natural | Fabric | 2.0 | 2 | |

2/20 S/P BK | PVC | Black | Smooth | - | Natural | Fabric | 2.0 | 2 | |

2/25 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 2.5 | FDA | 2 |

2/30 S/FF PG | PVC | Petrol Green | Smooth | - | Natural | Flexible Fabric | 3.0 | Cold-Resistant | 2 |

2/30 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 3.0 | FDA | 2 |

2/30 S/P AG | PVC | Apple Green | Smooth | - | Natural | Fabric | 3.0 | Antistatic | 2 |

2/30 LR/SF AG | PVC | Apple Green | Longitudinal Lib | - | Natural | Silent Fabric | 3.0 | 2 | |

2/30 S/D W FDA | PVC | White | Smooth | PVC | White | Diamond | 3.0 | FDA | 2 |

2/30 S/D W | PVC | White | Smooth | PVC | White | Diamond | 3.0 | 2 | |

2/30 S/D AG | PVC | Apple Green | Smooth | PVC | Apple Green | Diamond | 3.0 | Antistatic | 2 |

2/38 S/P W | PVC | White | Smooth | - | Natural | Fabric | 3.8 | 2 | |

2/46 TS/P AG | PVC | Apple Green | Saw Tooth | - | Natural | Fabric | 4.6 | Antistatic | 2 |

2/50 RT/P AG | PVC | Apple Green | Rough Top1 | - | Natural | Fabric | 5.0 | No-antistic | 2 |

3/30 C/C W | Cotton | Natural | Cotton | Cotton | Natural | Cotton | 3.0 | 2ply cotton 1ply fabric | 3 |

3/40 S/P TAN | PVC | TAN Colour | Smooth | - | Natural | Fabric | 4.0 | No-antistic | 3 |

3/50 S/D AG | PVC | Apple Green | Smooth | PVC | Apple Green | Diamond | 5.0 | Antistatic | 3 |

3/40 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 4.0 | FDA | 3 |

| PU conveyor belt | |||||||||

1/08 S/P W U FDA | PU | White | Smooth | - | Natural | Impreg-nated | 0.8 | Antistatic | 1 |

2/15 M/P W U FDA | PU | White | Matt | - | Natural | Impreg-nated | 1.5 | Antistatic | 2 |

2/14 M/P PG U FDA | PU | Petrol Green | Matt | - | Natural | Impreg-nated | 1.4 | Antistatic | 2 |

2/21 S/P W U FDA | PU | White | Smooth | - | Natural | Fabric | 2.1 | Antistatic | 2 |

2/21 S/P W U KE | PU | White | Smooth | - | Natural | Fabric | 2.1 | Knife Edge Application | 2 |

2/30 S/P

W U FDA | PU | White | Smooth | - | Natural | Fabric | 3.0 | Antistatic | 2 |

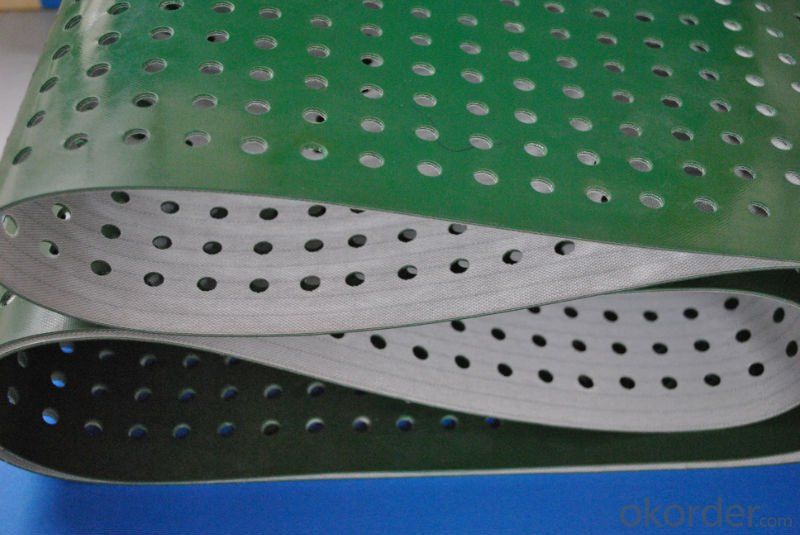

Pictures of PVC Conveyor Belt

Pls contact me freely if any inquiry or questions,thank you!

- Q:What is the rubber composition and function of the airplane tyres?

- Polybutadiene rubber is prepared by the solution polymerization of butadiene butadiene rubber, with excellent cold resistance, abrasion resistance and flexibility, but also has good anti-aging properties. Polybutadiene rubber is mostly used in the production of tires, a small part for manufacturing cold products, cushioning materials and belt and rubber shoes. Butadiene rubber drawback is the tear resistance of the cross, wet skid resistance is not good. Isoprene rubber is the abbreviation of polyisoprene rubber. It is produced by solution polymerization. Isoprene rubber, like natural rubber, has good elasticity and wear resistance, excellent heat resistance and good chemical stability. Isoprene rubber (not before processing) strength was significantly lower than that of natural rubber, but the quality uniformity, processing performance is better than natural rubber. Isoprene rubber can be used instead of natural rubber to make heavy-duty and off-road tires, and can also be used to produce all kinds of rubber products.

- Q:What is the difference between rubber expansion joint and rubber joint?

- The expansion joint is also called expansion device, expansion joint and compensator. It is divided into several types, such as ripple compensator, sleeve compensator, rotary compensator and square natural compensator, and also has intubation type expansion joint. Among them, the corrugated compensator is more commonly used, mainly to ensure the safe operation of the pipeline, and has the following functions: 1.. Compensating the axial, transverse and angular thermal deformation of the absorption pipeline. 2. vibration absorption equipment to reduce the impact of equipment vibration on the pipeline. The deformation of the pipeline 3., absorption of seismic subsidence.

- Q:How to maintain and store the rubber material?

- Rubber itself is a shelf-life, you can ask the supplier to warranty, above all, as fillers, such as calcium carbonate, carbon black, long time no problem, also have a shelf life of antioxidant promoter, especially individual species. When storing, pay attention to fire prevention, moisture-proof, away from the high temperature, avoid direct sunlight, of course, the general "first in first out" is a must follow the truth.

- Q:How can the frictional properties of rubber improve?

- Because of its high elasticity and low modulus, the friction and wear properties of rubber are greatly affected by their physical and mechanical properties. The hardness of rubber is smaller, contacting with a rigid object, the real contact area is large, and the real size of the contact area is an important factor, so the friction rubber hardness, have more effect on the friction performance.

- Q:What are the forming methods of rubber products?

- Calendering is the process in which material is subjected to elongation. The main equipment for rolling forming is three roller or four roller calender. The three roller calender is achieved by rotating the pressure of the two roller. When the rubber material passes through the roller gap, the rubber strip is expanded into a certain sectional shape under the action of pressure, or the process of gluing is realized on the fabric. It is used for sizing, pressing, spinning, gluing and gluing of textile and steel cord, as well as the laminating of film and film, film and adhesive fabric.The basic procedure of calendering process includes: mixing and preheating glue; fabric guiding and drying (and sometimes dipping); rubber sheeting in four roll and three roll calender on or in textile and rubberized calendering semi-finished products cooling, crimping, cutting and placing etc..In rolling before the need to preprocess the rubber and textile, rubber calender before entering, to turn it in the hot refining mill, this process is called thermal refining or preheating, the purpose is to improve the mixing uniformity of refined rubber material, further increase the plasticity, increasing the temperature increase high plasticity. In order to improve the bonding performance of rubber and textile, ensure the rolling quality, need drying of the textile fabric, moisture content control in 1% ~ 2%, the moisture content is too low, the textile hardens, easily damaged during the calendering, high water content, poor adhesion.

- Q:What kind of product is suitable for rubber trimmer? Where's the rubber trimmer?

- Rubber products, silica gel products, special rubber products only need to have the rubber parts of the dismantling groove, and the diameter of the rubber inside the 100MM can be used as trimming machine.

- Q:Rubber rolling process for making rubber products

- The rolling process has become a rolling process.The principle of rolling process: using pressure between the calender roller, the material plastic flow deformation, the final film made with the size and geometry of the provisions of section a section, or the rubber covering process in textile or fabric made of metal surface has a certain thickness of the tape section.

- Q:Why is natural rubber a strategic material?

- Rubber is an important strategic material, in the national defence application is very extensive, for example, a tank with more than 800 kg of general rubber; thirty thousand ton warship with sixty-eight tons of rubber, military equipment, air force facilities, almost all defense engineering rubber footprint. The use of rubber made ship, tent, warehouse and protective equipment, clothing etc. there are many varieties of bath water. As for the anti - tip technology needs high temperature, low temperature, oil resistance, high vacuum resistance and other special properties of the rubber, the constitution of 0 products is indispensable. With the development of national defense modernization, rubber, which is capable of resisting the temperature range of minus 100-400 DEG C and capable of resisting various acids, bases and oxidants with special properties, is being developed and manufactured.

- Q:How can I get rid of the rubber?

- You smell the smell from the vulcanized rubber residues, not much of the flavor is generally placed in a cool ventilated place, you can, and if the smell is large, you can use rubber deodorant, supermarkets generally sell

- Q:Rubber products labeled Huai gum can improve wear?

- In accordance with the requirements of the inquiry, the tire carbon black is a special production, usually oil to produce, mainly in the heavy oil products, coal, coal tar and other raw materials as a result of incomplete combustion

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Weight PVC PU Conveyor Belt Wood Application

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords