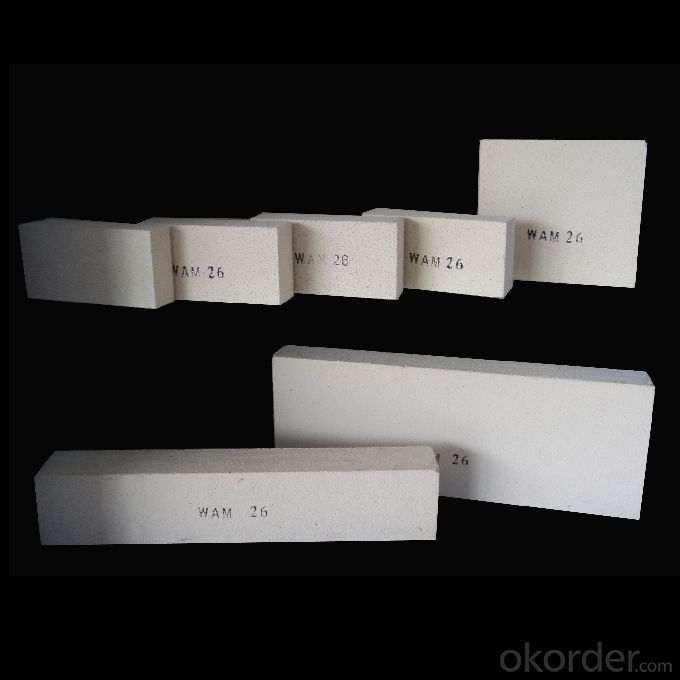

Insulation Fire Brick, Mullite Brick,Light Weight Refractory Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Insulation Fire Brick, Mullite Brick,Light Weight Refractory Brick

| Place of Origin: | (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | 30% | Al2O3 Content (%): | 50% | MgO Content (%): | 0.1% |

| CaO Content (%): | 0.1% | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0.1% |

| SiC Content (%): | 0.1% | Model Number: | JM-23 | Brand Name: | |

| color: | yellow white |

Packaging & Delivery

| Packaging Detail: | wooden pallet |

| Delivery Detail: | within 20 days |

Specifications

refractory mullite brick

1. Low density

2. High purity

3. Low thermal conductivity

4. Excellent thermal shock resistanc

Product Description for Insulation Fire Brick, Mullite Brick,Light Weight Refractory Brick

ADVANTAGES:

Light weight and low thermal conductivity allows thinner furnace walls

Maintain stable structural strength throughout ambient to maximum service temperature

Low heat storage results in rapid cooling and heating operation

Low iron and impurities to enhance reducing atmosphere

High thermal shock resistance in preventing spalling

Non standard sizes and shapes are available upon request

Product Uses

APPLICATION:

· Furnace repair

· Furnace, kiln, reformer and boiler linings

· Furnace door linings and seals

· Reusable insulation for steam and gas turbines

· High temperature insulation for kiln and furnace

· Primary reformer heater insulation

· High temperature insulation gaskets

· Expansion joint seals

· Glass furnace crown insulation

· Field steam generator lining

· Nuclear insulation applications

· Thermal reactor insulation

· Flexible high temperature pipe insulation

· Investment casting mold wrapping

· Removable casting mold wrapping

· Removable insulating blankets for stress relieving welds

· Pressure and cryogenic vessel fire protection

· Soaking pit seals

· High temperature filtration

· Incineration equipment and stack linings

· Petrochemical process heater fiber lining

· Heat treating furnace or intermittent (shuttle) kiln lining

· General furnace backup insulation

· Heat seals for kiln car or furnace door

· Electrical insulator

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, mortar, cement, ceramic fiber products, and more.

- Q:Are insulating fire bricks resistant to high-velocity gas flow erosion?

- Yes, insulating fire bricks are generally resistant to high-velocity gas flow erosion. These bricks are designed to withstand high temperatures and are made from materials that can withstand the erosive effects of gases flowing at high velocities. However, the resistance may vary depending on the specific composition and quality of the fire bricks.

- Q:Can insulating fire bricks be used in cement kilns?

- Yes, insulating fire bricks can be used in cement kilns. These bricks have high thermal insulation properties, which help in reducing heat loss and increasing energy efficiency in the kiln. Additionally, they can withstand high temperatures and provide effective insulation, making them suitable for use in cement kilns.

- Q:Are insulating fire bricks environmentally friendly?

- To a certain degree, insulating fire bricks can be deemed environmentally friendly. These bricks are crafted from abundant and readily accessible natural materials like clay, shale, and other minerals. Consequently, they do not contribute to the depletion of our natural resources. Furthermore, insulating fire bricks are engineered to possess low thermal conductivity, which aids in diminishing energy consumption. By utilizing these bricks, buildings can achieve better insulation, resulting in reduced heating and cooling requirements and, subsequently, decreased greenhouse gas emissions. Nevertheless, the manufacturing process of insulating fire bricks does have some environmental repercussions. The firing process necessitates high temperatures, which can lead to air pollution and greenhouse gas emissions. Additionally, extracting the raw materials for these bricks may cause some environmental disturbances. To truly assess the environmental friendliness of insulating fire bricks, it is vital to take into account the entire life cycle, encompassing raw material extraction, manufacturing, transportation, and disposal. Furthermore, comparing them to alternative insulation materials can offer a more comprehensive perspective on their environmental impact. In conclusion, while insulating fire bricks possess certain eco-friendly qualities such as being made from natural materials and reducing energy consumption, their overall environmental impact should be assessed holistically.

- Q:Can insulating fire bricks be used in the construction of fireplaces?

- Insulating fire bricks are a viable option for fireplace construction. These bricks are specifically designed to endure high temperatures, making them perfect for lining the inside of a fireplace. Their exceptional thermal insulation capabilities ensure that heat is contained within the fireplace, preventing excessive heat transfer to the surrounding structure. This not only enhances the efficiency of the fireplace but also reduces the likelihood of damage to nearby walls. Furthermore, these bricks are lightweight and easy to work with, making them convenient for construction purposes. They are also resistant to thermal shock, meaning they can withstand sudden temperature changes without cracking or breaking. Overall, insulating fire bricks are a dependable and efficient choice for building fireplaces.

- Q:Can insulating fire bricks be used in residential applications?

- Yes, insulating fire bricks can be used in residential applications. They are commonly used in residential fireplaces, wood-burning stoves, and pizza ovens to provide insulation and increase energy efficiency. Their high heat resistance and insulating properties make them suitable for these applications.

- Q:Can insulating fire bricks be used in the construction of thermal storage units?

- Yes, insulating fire bricks can be used in the construction of thermal storage units. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for thermal storage applications where heat retention is crucial.

- Q:Are insulating fire bricks suitable for outdoor use?

- Insulating fire bricks are generally unsuitable for outdoor use because they have lower density and higher porosity compared to other bricks. These bricks are specifically designed for high-temperature environments like furnaces and kilns, where they offer exceptional insulation. However, when subjected to outdoor elements, insulating fire bricks can absorb moisture and become susceptible to cracking or deterioration over time. For outdoor purposes, it is generally advised to opt for dense fire bricks or bricks explicitly made for outdoor use, as they possess superior durability and resistance against weather conditions.

- Q:Can insulating fire bricks be used in the construction of drying ovens?

- Yes, insulating fire bricks can be used in the construction of drying ovens. These bricks are designed to withstand high temperatures and have excellent thermal insulation properties, making them ideal for creating a heat-efficient environment in drying ovens. They can help in maintaining a consistent temperature and preventing heat loss, thereby improving the drying process and energy efficiency of the oven.

- Q:Are insulating fire bricks suitable for applications requiring low thermal conductivity?

- Yes, insulating fire bricks are suitable for applications requiring low thermal conductivity. Insulating fire bricks are specifically designed to have low thermal conductivity, making them ideal for situations where heat insulation is necessary. These bricks are made from lightweight and porous materials, such as clay and other refractory materials, which provide excellent insulation properties. The porous structure of insulating fire bricks traps air within the material, reducing heat transfer and resulting in low thermal conductivity. This makes them effective in applications such as kilns, furnaces, and other high-temperature environments where minimizing heat loss is crucial. Overall, insulating fire bricks are a reliable choice for applications that demand low thermal conductivity.

- Q:Can insulating fire bricks be used in the construction of glass melting furnaces?

- Insulating fire bricks are indeed applicable for constructing glass melting furnaces. These bricks are specifically designed to possess exceptional heat resistance and endure exceedingly high temperatures. Their low thermal conductivity allows for efficient heat retention and minimal heat loss. In glass melting furnaces, where temperatures can reach up to 1600°C (2912°F) or even higher, insulating fire bricks serve a pivotal role in maintaining the desired temperature within the furnace. By utilizing these bricks as the lining for the furnace, the heat generated during the melting process can be effectively contained, resulting in improved energy efficiency and reduced heat loss. Additionally, insulating fire bricks are lightweight and exhibit remarkable thermal shock resistance, making them highly suitable for glass melting furnaces that experience sudden temperature fluctuations. This ensures that the bricks will not crack or break under the extreme conditions present in the furnace. Overall, incorporating insulating fire bricks into the construction of glass melting furnaces offers superior insulation, energy efficiency, and durability, rendering them an ideal choice for this application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Insulation Fire Brick, Mullite Brick,Light Weight Refractory Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords