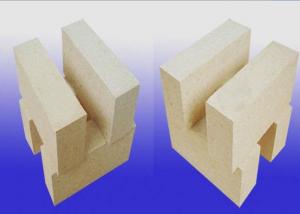

Inner Orange Glass Block

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9000 Pieces pc

- Supply Capability:

- 1000000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Introduction of Inner Orange Glass Block

1)We have various styles and designs

2)glass block is modernizational,environment-friendly decorative material.

Size(mm) |

Packing (pcs/ctn) |

Dimension (cm) |

Unit weight (kg) | Capacity/20’ | |

Without pallet |

With pallet | ||||

190*190*80mmclear | 6 |

39.5*26*20 | 2.3 |

9000pcs |

7200pcs |

190*190*80mmcolor | 6 |

39.5*26*20 | 2.3 |

9000pcs |

7200pcs |

190*190*95mmclear | 6 |

39.5*30*20.5 | 2.5 |

7500pcs |

4800pcs |

145*145*95mmclear | 8 |

42*30.5*16 | 1.7 |

11200pcs |

8960pcs |

145*145*80mmclear | 10 |

43*30*16 | 1.5 |

12500pcs |

10400pcs |

- Q:What are the general practices of quality control of decorative works? What is the general loss of material loss?

- New building wall materials and wall insulation technology Abstract: The new building wall material is not to consume arable land, destruction of ecological and polluting the environment at the expense of industrial parts to meet the construction, construction mechanization, reduce the construction site wet operation, improve the construction Function and other modern construction industry requirements and the production of wall materials, on the current stage of our country refers to the concrete brick in addition to all the building outside the wall material

- Q:What are the low cost of using lightweight brick partitions and gypsum board partitions? Labor costs and materials costs together

- Light steel keel gypsum board wall construction is simple, single gypsum board partition wall total cost is low, but its strength, moisture and water quality is far less than light brick wall, brick wall is not only high labor costs, and wall follow There are mortar of the process, than the stone to wear Cao Fei 丨 crossing to kill intestinal paste board wall complex many.

- Q:Building construction block, small steel mold code height is how much?

- Not more than 1.5 meters. Construction block, small steel mold code height of not more than 1.5 meters. Block is a masonry with masonry, is a new type of wall material, shape mostly right angle hexahedron, there are a variety of shaped blocks. The main specifications of the block length, width, or height of one or more were more than 365mm, 240mm or 115mm, but the block height is generally not greater than the length or width of 6 times the length does not exceed the height of 3 times. The block is made of concrete, industrial waste (slag, fly ash, etc.) or local materials made of artificial blocks, the size than the brick, with simple equipment, the advantages of small masonry, in line with the construction of industrial development in the wall Body reform requirements. Blocks are divided into small blocks, medium blocks and large blocks by size and mass. Block series of the main specifications of the height of more than 115mm and less than 380mm called the small block, the height of 380 ~ 980mm called medium block, height greater than 980mm called large block.

- Q:What is the difference between packing density and bulk density in building materials?

- Bulk density: for the scattered material; such as cement, sand

- Q:What are the factors that affect masonry quality in masonry structures?

- In front of someone to answer a very comprehensive, I will look at his top bar Oh!

- Q:Is the ceramsite concrete block and cement brick the same product?

- Autoclaved aerated concrete block is made of calcium powder (such as cement, lime) and siliceous materials (such as sand, fly ash Fu Tai Ju Gao Gao Dian Dian poke top pull ash, slag) Air-entraining, agitating, pouring, inflating, pre-cutting, and then by high-pressure steam curing porous silicate block

- Q:Why are energy-saving wall building materials now? What kind of material is more practical?

- energy conservation and environmental protection is an important policy for sustainable development in China

- Q:What is the height of the building material stacking at the construction site? Like red brick, steel, template or something

- Saving land, but also to facilitate the extraction of steel

- Q:What is the difference between the filling wall and the block wall? Are aerated concrete blocks in the frame structure filled with walls or blocks? The more detailed the better.

- The difference is that the filling wall is sorted by function, and the block walls are sorted by material

- Q:Commonly used building energy - saving materials are the names of their respective roles

- External insulation energy-saving system: sheet insulation: polystyrene foam insulation board (eps), extruded polystyrene foam board (xps), polyurethane foam insulation board (pur), phenolic board, rock wool insulation Board, foam glass insulation board paste insulation: eps / xps / pur powder particles insulation paste, glass beads insulation mortar, ceramsite concrete and so on But also to determine the classification of the building to determine the external insulation of the fire rating A1B1B2 several common fire resistance level and the construction practices are also a lot of to the outside of the fire insulation, For the building category brought about the requirements of the fire-resistant sheet of fire resistance (their own look at the information this is too much)

We are one of the biggest productive bases of glass block in China. We have many years manufacturing experience with all kinds of style and colour. Providing excellent quality and competitive price, are enjoying a high reputation all over the world market. Our company specializes in manufacturing a variety of building materials and chemical products.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei,China (Mainland) |

| Year Established | 1999 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Mid East; Eastern Asia; Western Europe |

| Company Certifications | ISO 9001:2000;ISO 14001:2004 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Inner Orange Glass Block

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9000 Pieces pc

- Supply Capability:

- 1000000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords