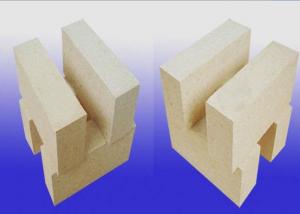

Refractory AKZ-85 Alumina Bubble Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 Tons m.t.

- Supply Capability:

- 5000 Tons per Month alumina bubble brick in stock m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of Refractory AKZ-85 Alumina Bubble Brick

1.High compressive strength

2.Excellent thermal shock resistance

3.High thermal efficiency of the kiln

Description of Refractory AKZ-85 Alumina Bubble Brick

alumina bubble brick refractory brick bricks have high-alumina bauxite powder and refractory clay as raw materials and some inflammable additions, shaped by tamping or extrusion pressing and fired in high-temp tunnel kiln after being dried.

alumina bubble brick refractory bricks have three brands in accordance with their bulk densities, which are decided by the amount of the inflammable additions. alumina bubble brick refractory bricks with large bulk density have the features of high mechanical strength and small change of load at a high temperature.

Used alumina bubble brick Features

·High compressive strength

·Excellent thermal shock resistance

·Able to lower the heat capacity of the furnace wall

·High thermal efficiency of the kiln

·All types of products available as customers require.

Application of alumina bubble brick

alumina bubble brick can be Used in heat-insulating layers and furnace linings of thermal equipment, such as, roller kilns ceramics, heating furnaces petrochemical reforming, reforming furnaces, soaking ptis metallurgy and blast furnaces.

Physical and chemical index of Refractory AKZ-85 Alumina Bubble Brick

Item | AKZ-85 | AKZ-90 | AKZ-99 | |

Chemical composition | Al2O3 | ≥85 | ≥90 | ≥99 |

SiO2 | ≤13 | ≤8 | ≤0.2 | |

Fe2O3 | ≤0.5 | ≤0.5 | ≤0.5 | |

Apparent Porosity% | 58-62 | 58-62 | 58-62 | |

Bulk Density g/cm3 | 1.4-1.7 | 1.4-1.7 | 1.4-1.7 | |

Cold Crushing Strength Mpa | ≥12 | ≥10 | ≥9 | |

0.1Mpa Refractoriness Under Load T0.6 °C | ≥1650 | ≥1700 | ≥1700 | |

Permanent Linear Change On Reheating

(%)1500°CX2h | ±0.3 | ±0.3 | ±0.3 | |

20-1300°C Thermal Expansion % (x 10-6) | 0-7.8 | 0-8.0 | 0-8.6 | |

Thermal Conductivity(Average 800°C) W/(M.K) | ≤0.8 | ≤1.3 | ≤1.5 | |

Max Service Temperature °C | 1680 | 1700 | 1800 | |

- Q:Ok so I want to pour cement in this, im assuming, 12 by 8 ft sized area. How mane bags of cement would I need? How many boards do I need? Do I even need them? Do I also need that wire for the bottom? How much does that run?Can anyone give an estimate of the total cost?

- What okorder

- Q:I have an 8x10 slab against the house, I would like it to be extended to an 12x12. How much would it cost to have someone pour it?

- Yeah! I always take advice about CONCRETE from some one that calls it CEMENT. You are talking about adding 2' to one side of the slab, and 4' to another. This is difficult to make work, because the additional slabs will always be separate and will move independently from the existing slab. You can dowel the slabs together, if you have a rotor-hammer drill (most people don't). If you attempt this yourself, with no experience with CONCRETE, you will probably not be happy with it. Call a Flat-work Contractor and have them give you a quote, then you can decide if it is worth your inexperienced time (cause it will take you twice as long to do it), and the price quotes are FREE.

- Q:if it is is it renewable or nonrenewable?

- Cement is a nonrenewable resource made from limestone. Limestone is comprised of mostly Calcium Carbonate.(CaCO3) a naturally occurring rock type. It is mine from the ground in open quarries or underground mines. It is then ground very finely and heated to make it into cement powder. Once it is used, it is used.

- Q:Building materials distribution business projects can increase the cement products and steel it?

- Definition of cement: powdered hydraulic inorganic cementitious material

- Q:a small block of cement cost. Our driveway needs to be fixed, a 4x4 block has to be re poured.

- Look in your Yellow Pages under Cement,Transit Mix give them a call.The price where I live will be different than where you live.Try It. 10/10

- Q:I had the foundation repaired in my basement a while back and the dust from the cement is still there, I've washed the floor about 5 times since and it still hasn't come off, got any suggestions about what I should do?

- The cement is doing what it should. A previous questioner had trouble with the concrete floor in his garage. He spilt some vinegar on the floor and found it had eaten the surface the next day. If you can convince your wife to let you have some for an experiment ??? Beware vinyl stained by vinegar and swapping one problem for another. GL>

- Q:i used cement to seal large gaps in the house, but in an upside down suface where i used lots of it on, touching it makes parts of the surface turn into powder and chunks fall off. I did it rudimentary with my hands and a smoothed it as best as i could then but still looks and feels messy. The holes are filled and its solid, the surface though is powdery.

- My advice is to try experimenting with just 1 area that needs work. Generally, if you use less water, pack it in tight, it will be stronger more dense. If you have the time patience, you will get the right mixture gain experience. A little internet will help. Then move on to the rest of the areas that need work.

- Q:All I can find is on Wikipedia, but I need more than that!I would be really grateful!!Thank you!

- You are looking at lime based mortar and concrete (opus siginum to the Romans). I have used ordinary builders lime, dry in bags, and mixed it as you would with cement 5:1, and let it rest for around 24 hours before use. the great thing about lime based mortar is that when it begins to go hard, you can add more water and mix it again without loss of strength as would be the case with O.P.C. It does take a long time to set, weeks if the weather is cold and wet but the resulting mortar is very good for stone and soft brick as it will allow the structure to move and settle, also when frost freezes the water in the wall, it is the lime mortar that is blown out, not the stone or brick.

- Q:I was told I could use rubber cement in place of liquid masking film (Frisket) for masking off areas in my watercolors. Is it gentle enough that it won't rip the watercolor paper when removed?

- No. That is, yes, you can use it, and it may not rip top quality papers. But rubber cement is a very bad choice if you want your art to last. It is harmful to cheaper papers and to all work over time. That's why Frisket, and other fine art masking fluids were developed. So if you care about the long-term preservation of your art, do not use rubber cement. For student quality work, or something you plan to toss once you're finished, fine.

- Q:I have a very ugly cement backyard area, were the homeowners before me thought it was cool to put orange, red and yellow tennise court paint down and now thats chipping away it is really ugly. So can I just lay stone tile down to make it look better or what can I do. The cement is probly 25 years old no cracks that I can see their is one corner that is lower then the rest mybe from settling maybe from a lazy DIY'er.

- From what you say, the concrete appears to be stable and will probably make a good underlayment for your tile. Your problem, however, is the paint on the surface. Any tile installed on such a surface will come up along with the paint if and when it delaminates from the concrete. By scoring, scraping, chemically, or some means; bring the existing finish down to raw concrete and bipass a nightmare down the road. Good luck!

1. Manufacturer Overview |

|

|---|---|

| Location | Henan,China (Mainland) |

| Year Established | 2007 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe |

| Company Certifications | business license |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai,Qingdao,Tianjin |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian |

| b)Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

Refractory AKZ-85 Alumina Bubble Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 Tons m.t.

- Supply Capability:

- 5000 Tons per Month alumina bubble brick in stock m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords