Injection Molding Machine LOG-130S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Preform Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG130-A8

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 196g-239g-277g

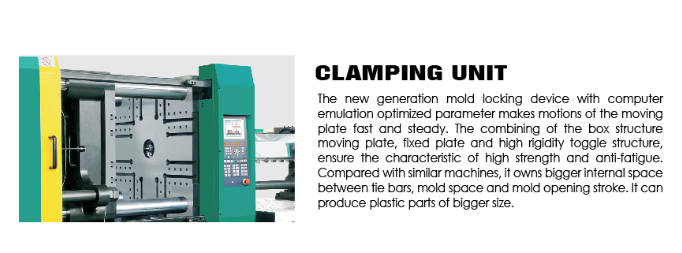

Clamping Force: 1300KN

Opening Stroke: 380mm

Power(W): 11 Kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Voltage: 380V

Name: PET Preform

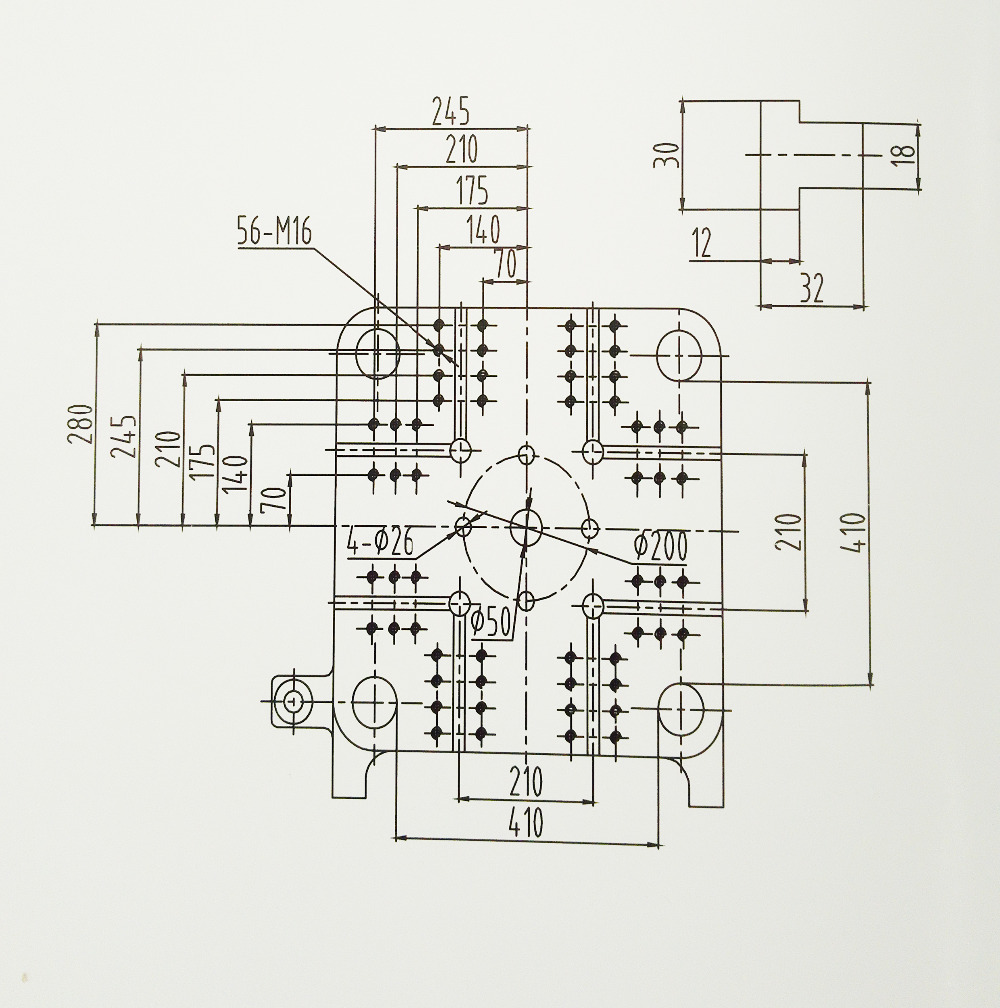

Space between tie bar: 410mm*410mm

Color: Green

Machine weight: 4T

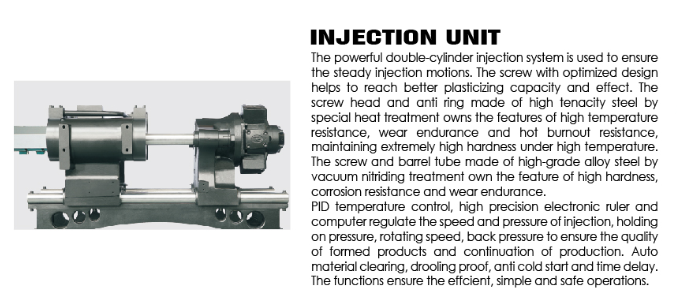

Screw Diameter: 38-45mm

Machine dimension(L*W*H): 4.6*1.2*1.8

Warranty: 1 Year

Material: Stainless Steel

Machine: Thermoplastic Injection Moulding Machine

| Description | Unit | LOG-130A8 | ||

| international recognized models | 416/130 | |||

| injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 215 | 263 | 302 |

| Shot volume | g | 196 | 239 | 274 |

| Oz | 6.9 | 8.4 | 9.6 | |

| Screw diameter | mm | 38 | 42 | 45 |

| Injection diameter | mpa | 193 | 158 | 138 |

| Screw L:D ratio | 22:01 | 20:01 | 18:01 | |

| Scerw steoke | mm | 190 | ||

| Screw rotate speed | r/min | 180 | ||

| CLAMPING UNIT | ||||

| Clamping force | kN | 1300 | ||

| Opening stroke | mm | 380 | ||

| Platen size | mm*mm | 610*610 | ||

| Space between tie bars | mm*mm | 410*410 | ||

| Maldthickness | mm | 150-430 | ||

| Platen Mix stroke | mm | 810 | ||

| Ejection stroke | mm | 120 | ||

| Ejcetion force | kN | 42 | ||

| Power/Elcetric Heating | ||||

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 12 | ||

| Heating power | kw | 7.7 | ||

| Number of temp.conteol | 4+nozzle | |||

| Other | ||||

| Cycle time | sec | 1.3 | ||

| Tank volume | L | 200 | ||

| Machine dimesions | m*m*m | 4.6*1.2*1.8 | ||

| Weight of machine | kg | 4000 | ||

Packaging Details: 20 GPcabinet Delivery

Delivery Detail: two weeks after get payment

| INJECTION | LOG130 | |||

| A | B | C | ||

| Shot volume | cm³ | 215 | 263 | 302 |

| Shot weight (ps) | G | 196 | 239 | 274 |

| oz | 7 | 8 | 10 | |

| Max injection rate | cm³/s | 97 | 118 | 163 |

| Screw diameter | mm | 38 | 42 | 45 |

| Plasticizing rate | Kg/h | 46 | 60 | 75 |

| Injection pressure | Mpa | 193 | 158 | 138 |

| Screw L:D ratio | 22:01 | 20:01 | 18:01 | |

| screw speed | r/min | 0~180 | ||

| CLAMPING | ||||

| Clamping force | Kn | 1300 | ||

| Opening stroke | mm | 380 | ||

| Platen size | mm*mm | 610*610 | ||

| Space between tie bars | mm*mm | 410*410 | ||

| Mold thickness (Min--Max) | mm | 150~430 | ||

| Hydraulic ejection stroke | mm | 120 | ||

| Hydraulic ejection force | Kn | 42 | ||

| Power Unit | ||||

| Hydraulic system pressure | Mpa | 17.5 | ||

| Pump motor | Kw | 11 | ||

| Heating capacity | Kw | 7.7 | ||

| Number of temp control zones | 4+ (nozzle) | |||

| GENERAL | ||||

| Dry-cycle time | sec | 1.3 | ||

| oil tank capacity | L | 200 | ||

| Machine dimensions | m*m*m | 4.6*1.2*1.8 | ||

| Machine weight | kg | 3550 | ||

Platen Dimensions:

product 1

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

- Q:What does injection machine mean by "short shoot"?

- Short shot is not to go slow glue, injection molding is not filled with the entire cavity, only a small part of filling, next time a little more, so that several times filling, and finally filling, slow the entire cavity. The function is to see if the glue is even. Especially in the multi cavity, you must try this way.

- Q:RTBrother recently understand the injection mold related knowledge, about the forming cycle of this problem, I do not know whether this cycle can be estimated according to the relevant parameters, please advise!Forming cycle: the time between the previous product and the next product, including the time taken by the manipulator, and so on. I am for the new quotation, not too precise, but not too far away, trouble expert advice, small first, thank you very much!

- If a trial can be used to test out the stopwatch + wide release time, not the trial production of new software available for calculation, but the structure of a product cycle also depends on the size and thickness of the product, is complex and molding technology to all of these affect the product cycle, your statement is not very clear and it is difficult to give you a more accurate estimate of the cycle, experienced personnel can structure size, thickness, the product was estimated, and more reasonable!

- Q:Injection molding machine barrel, and the height of about how to adjust?

- The screw you're shooting is just adjusting the height and the left and right. If the deviation is large, the fixed seat, the piston rod, the pressure plate and the screw should be loosened.

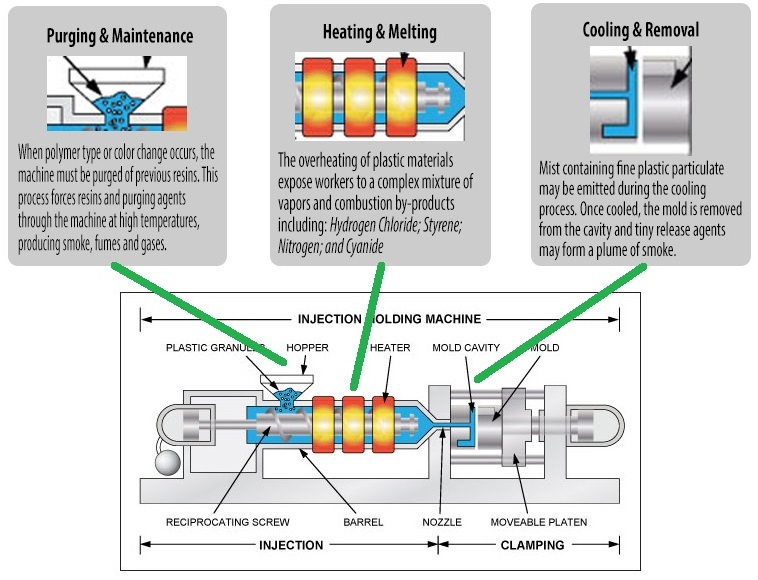

- Q:The working principle of injection molding machine

- The working principle of injection molding machine and injection syringe with similar, it is the use of screw (or piston) thrust, the plasticizing good molten state (i.e. viscous flow) plastic injected into the mold cavity closed good after curing stereotypesmade the process of the products.Injection molding is a cycle process, each cycle mainly include: quantitative feeding - melt plasticization - pressure, injection - filling mold cooling - die opening pieces. Take out the plastic parts and then close the die for the next cycle.Injection molding machine operation items: injection molding machine operation items, including control keyboard operation, electrical control system operation and hydraulic system operation three aspects. The injection process, feeding action, injection pressure, injection speed, ejection type, temperature monitoring, injection pressure and back pressure adjustment are carried out respectively.The molding process of the general screw injection machine is first granular or powdered plastic into the machine barrel and then through the rotation of the screw and barrel wall heating the plastic as molten state, then the machine mold and the injection seat moves forward, to close the mold gate nozzle, the pressure oil through to the injection cylinder then, the screw to move forward at a high pressure and speed will melt into the closed mold temperature low, after a certain period of time and pressure (also called pressure), cooling, the curing, can remove mold products (pressure to prevent molten material the reflux, supplementary materials, to ensure the products with the mold cavity and the density and size tolerance in a certain cavity).

- Q:Introduction to injection molding

- Injection molding is a method of producing shapes in industrial products. Products are typically molded by rubber injection and plastic injection. Injection molding can also be divided into injection molding, die casting and die casting. Injection molding machine (referred to as the injection molding machine or injection molding machine) is plastics molding equipment of thermoplastic or thermosetting material using plastic mold made of various shapes, injection molding by injection molding machine and mold.

- Q:Injection molding machine clamping force appropriate, can speak a little detail, thank you

- The clamping force of the injection molding machine varies greatly with the injection molding end surface area. For example, the 100 ton injection molding machine has an end area of 80 square centimeters, and the pressure gauge in the mould indicates about 120. Clamping force is appropriate, (about 80, 90 tons or so) qualified products. If the end area of a product is 50 square centimeter, the pressure gauge in the mould indicates about 80, and the clamping force is about 50 or 60 tons. Can produce qualified products. The general situation is to explore their own experience, and grasp their own. There are no definite rules. Excessive clamping force. The injection molding machine is seriously worn and suffers great losses. Clamping force is too small, products appear (cloak or gel edge). For reference only.

- Q:What exactly does the KO hole in the injection mold mean? Where is the general position?

- The KO hole, also called the top roller hole, is made on the rear die panel of the mould. The top rod can be directly pushed to the thimble plate when the injection top is out, and the hole dug on the panel is used for avoiding the empty. KO with the sprue hole position is on the same axis.

- Q:How does the steel injection machine go to the origin?

- 3, with the clamping force of 15% of the set, if the spring die can not be completely closed, or want to reduce the mold contact time, in the range of +-10%, adjust the mold low pressure protection pressure. In the setting of clamping stroke, pressure mold protection must be set by the mold temperature reaches the set value can be accurately set a low voltage protection, because in the cold to be better at the mold temperature reaches the set value of thermal expansion is not locked. 6.2 after the set with A4 (40*40MM) A4 with butter wet paste in the mold safety parting surface, and then clamping voltage protection effect test. If after the mold, the machine will alarm, OK, otherwise reset the low voltage protection parameter until OK.This answer is recommended by users

- Q:The outer ring of the injection machine is against the ring. Do you blame the anti ring?It was normal to play PBT before. Now the storage stroke is 10 centimeters long or unstable

- Non return wear, the cylinder will also be corresponding wear, extended the spray stroke, the room filled, leakage will be more

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection Molding Machine LOG-130S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords