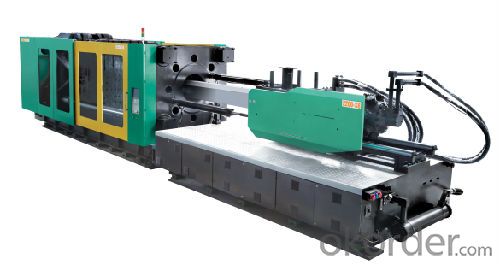

Injection molding machine LOG-2200S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 22000g

Clamping Force: 22000 kw

Power(W): 150 kw

Certification: ISO9001:2008

After-sales Service Provided: Engineers available to service machinery overseas

Packaging & Delivery

| Delivery Detail: | 75 days |

|---|

Description | Unit | LOG-2200A8 | ||||

international recognized models | ||||||

injection | B | C | D | |||

Tjeoretical injection volume | cm³ | 13183 | 15000 | 16933 | 24192 | |

Shot volume | g | 12043 | 13700 | 15468 | 22075 | |

Oz | 442 | 480 | 542 | 774 | ||

Screw diameter | mm | 150 | 160 | 170 | 185 | |

Injection diameter | mpa | 186 | 164 | 145 | 153 | |

Screw L:D ratio | 23.5:1 | 22:1 | 20.7:1 | 22:1 | ||

Scerw steoke | mm | 750 | 900 | |||

Screw rotate speed | r/min | 0-80 | 0-60 | |||

CLAMPING UNIT | ||||||

Clamping force | kN | 22000 | ||||

Opening stroke | mm | 1850 | ||||

Platen size | mm*mm | 2450*2300 | ||||

Space between tie bars | mm*mm | 1750*1600 | ||||

Maldthickness | mm | 700-1700 | ||||

Platen Mix stroke | mm | 3550 | ||||

Ejection stroke | mm | 420 | ||||

Ejcetion force | kN | 550 | ||||

Power/Elcetric Heating | ||||||

Hydralic system pressure | Mpa | 17.5 | ||||

Pump motor | kw | 37*4 | ||||

Heating power | kw | Nozzle | 135 | |||

Number of temp.conteol | 7+nozzle | |||||

Other | ||||||

Cycle time | sec | 18 | ||||

Tank volume | L | 4100 | 4100 | |||

Machine dimesions | m*m*m | 17.5*4.2*3.7 | 18.5*4.8*4.3 | |||

Weight of machine | kg | 136000 | ||||

Packaging & Shipping

- Q:What's the pressure and speed of melt press in injection molding machine?

- Sol pressure: commonly known as back pressure, refers to the back of the screw when the pressure carried. Sol speed: injection molding machine in the gum into the screw drive, the screw moving speed, that is, the plastic into the screw speed.The new technology adopts the switched reluctance servo motor to drive the hydraulic pump and drive screw to realize the valveless servo hydraulic system with high efficiency and energy saving and high reliability.

- Q:What's the injection?

- 1 、 injection molding is an industrial product modeling method. Products are typically molded by rubber injection and plastic injection. Injection molding can also be divided into injection molding, die casting and die casting. Injection molding machine (referred to as the injection molding machine or injection molding machine) is plastics molding equipment of thermoplastic or thermosetting material using plastic mold made of various shapes, injection molding by injection molding machine and mold.2, work content: run injection molding machine, take products, Xiao Shui kou. But now most companies are using mechanical hand, no operator switches the injection machine door.3, injection molding process: the process mainly includes mold - filling - holding pressure - cooling - release 5 stages.

- Q:Which high-speed machine is stable in domestic injection molding machine?

- Bo machine can also, moderate price, stable performance, I used to produce mobile phones accessories

- Q:4000 grams of injection molding machines, tons of sea and sky

- 530 ton tonnage is clamping force. Gram is the amount of injection, that's ok.

- Q:What are the requirements of screw plating in injection molding machine?

- Usually plated hard chromium, it can be made transparent material. The surface requires no blisters, plating layer is not allowed off phenomenon.

- Q:What factories in Shenzhen area have injection molding machines? What's the number?

- Go wrong in Shenzhen can see the injection molding machine,

- Q:Universal charger, product weight 28 grams / sets, mold two (surface shell, bottom shell), one out of eight, material: 7000 yuan / ton, to two 180T injection molding machine production. Since I have just entered the line, how much money can you ask me to do? In this small woman to give you a thank

- The new machine needs 300000 powder machine, 4000 or so change the triangle of the mould, the Longmen frame is several thousand, the cooling water channel, the water pump is several thousand, the cable is several thousandFor three-phase power goes 349Annual tax paymentThe minimum wage is at least three months at least for 12500/ monthsRent a plant for fifty thousand or sixty thousand a yearThe material charge depends on how much you receive and when you collect itYou may have considered buying an old machine, but if you have a large quantity, the old machine is easy to go wrong, and the quantity is less. It's more cost-effective to find someone else to process itAdd a plus, look at the small amount, it is best to find someone to process

- Q:I want to know something about the purchase of high-end injection molding machinesCustomers in the whole power and hydraulic injection molding machine purchase process, those machine advantages, they are more concerned about, and if you choose to buy, then you will choose all electric or full hydraulic machine, why? To know a friend told me, we discuss together, thanked the boy in this

- All electric injection molding machine, injection molding machine Dongyang (TOYO), Sadegh (Sodick), FANUC injection molding machine injection molding machine (Fanuc)Day steel injection molding machine (JSW), Ke Chun injection molding machine (KeJun), two-color injection molding machine.

- Q:What kind of lubricant does the injection machine use?

- The main use of antiwear hydraulic oil, as well as 00-000, extreme pressure grease

- Q:transparent parts inside the bubble, how to solve this problem, non -, what is the cause?

- 1 back when there is air into the screw, increase the point back pressure, 2 shooting back position is too far, appropriate to reduce 3, control the temperature of the mold, do not use cold water 4 injection molding process adjustment, using multi-stage injection and packing forms and other reasons

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection molding machine LOG-2200S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords