Industrial Power Nylon Flat Transmission Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Industrial Power Nylon Flat Transmission Belt

Application

Widely used in Machinery, textile, printing and dyeing, woodworking machinery, packaging, printing, post and telecommunications, food, stone, metal processing, logistics, tobacco industry

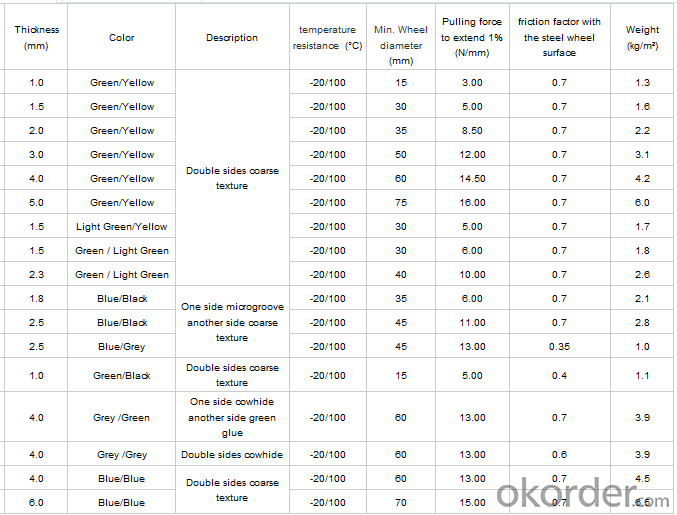

Specifications

Advantage

1. Good elasticity, anti-impact

2. High adhesion, good flexing capacity

3. Stable transmission

4.Good antistatic performance

5. Good resistance to moisture and heat, corrosion resistant

6. Good wear ability and long service life

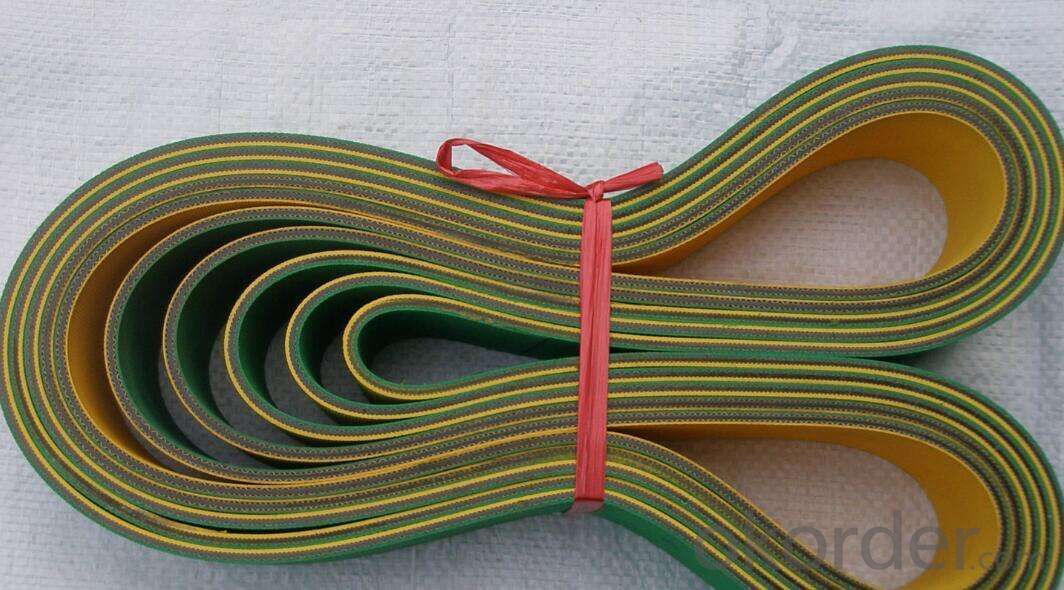

Flat Transmission Belt Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the Flat Transmission Belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q:What is the difference between natural and synthetic rubber?

- Natural rubber is mainly derived from the Hevea tree. When the epidermis of this rubber tree is cut open, it will shed milky juice. It is called latex, and the latex will be natural rubber when it is condensed, washed, molded and dried.

- Q:When rubber products are hardened, what methods soften?

- Either hardening or vulcanization. Vulcanized rubber becomes elastic rubber. This is an irreversible process. The elastomer can be changed into a plastic regenerated rubber by the desulfurization process.

- Q:How do you remove the rubber on your new slippers?

- There must be some rubber smell, because the bottom containing rubber and plastic bags are used as fine without air so the rubber flavor will be heavier, and you wear for a period of time will not fall, or to buy after put in place of ventilation blowing for one or two days no taste.

- Q:Which is better waterproof performance, neoprene or silica gel?

- Silicone rubber (Silicone, rubber), sub heat vulcanizing (high temperature vulcanized silica gel HTV), room temperature vulcanized (RTV), in which room temperature vulcanization type and polycondensation reaction type and additive reaction type.

- Q:How to make mobile phone rubber coat non stick ash?

- Silicone mobile phone sets can not be stained with gray, if not stained with gray, it certainly does not slip ah (such as stainless steel)

- Q:How can rubber be made into rubber when it is made?

- Just cut off the rubber is not available, belongs to the first rubber, according to the products and the use of working conditions to set the formula, made of mixed rubber, vulcanized on the vulcanization machine with mold has been good, curing after trimming, testing, packaging. The required rubber products will be ready.The process flow of the production process is:Raw material preparation, plasticization, blending, molding, vulcanizing, cleaning and testing

- Q:What kind of product is suitable for rubber trimmer? Where's the rubber trimmer?

- Generally used for metal strip trimming, that is, after the strip of metal strips with a fixed tool to remove burr or chamfer on both sides of the required radian,Scope of application: used in tableware, stationery, hardware, sheet metal and other special equipment industry.Main functions: grinding and polishing of double sides of roll beltApplicable materials: stainless steel, copper strip, aluminum belt and other metal coil.It has the advantages of rough grinding, fine grinding and polishing. It is suitable for grinding the bevel and straight edges of metal belts of different sizes and thicknesses, and is equipped with grinding wheels and spare grinding wheels. The grinding wheel has the advantages of long service life, regular forming rules and high efficiency.

- Q:What are the causes of fracture in rubber products?

- Rubber products appear broken phenomenon, mainly for the following reasons:1, rubber products for a long time led to the phenomenon of fracture;2, too tired lead to rubber products broken;3, long-term exposure to ultraviolet light will cause rubber products broken;4, in the production of the use of chemical additives and materials conflict, resulting in incompatible and broken;5, the production process, the release of time is not appropriate, resulting in fracture (such as scratches);6, abrasive structure is irrational, lead to fracture;7, the use of materials is irrational, leading to fracture is also common;8, materials placed too long, in use, resulting in broken products, resulting in waste.

- Q:Comparison of physical properties of HNBR rubber material with other rubber materials

- HNBR has a high temperature resistance of 130~180 degrees, cold resistance of -55 ~ -38 degrees, and good mechanical properties, compared with other polymers, can meet the requirements of the automotive industry. HNBR with ZnO/ methacrylate (MAA) can be used to make V-belt, triangular V-belt, multi base rubber, vibration isolator and so on. It can also prepare sealing ring, sealing element, heat resisting tube and so on. In oil drilling, rubber products are required to withstand high temperature, high pressure, acid, amines, H2S, CO2, CH4 and other tests of steam. The products prepared by HNBR can be acid resistant, oil resistant and solvent resistant. With the ZnO/MAA HNBR reinforcement can be used for the production of drilling mud pump piston and protection box. In addition, the beating method HNBR can be used as a sealing washer washer made of paper oil industry and automobile industry. HNBR heat and radiation resistance properties than silicon rubber, fluorine rubber, poly four vinyl chloride is better, suitable for all kinds of rubber seals for power station, is also used as a hydraulic pipe, hydraulic seals, power station for cable sheath, can also be used for printing and fabric roller, weapons components and aerospace seals, cover, fuel capsule; HNBR latex can be used as a surface coating (painting), textile, paper, leather, metal, ceramic fiber, non-woven adhesive, and foam rubber, latex impregnated products etc.. In addition, with ZnO/MAA, peroxide and high wear furnace HNBR, its comprehensive performance is better than ordinary HNBR.

- Q:Is the odour emitted by industrial rubber poisonous?

- The rubber shaped blank after extruding; and then the textile materials and rolled hanging glue or glue (or metal) together formed into semi-finished products; finally after vulcanization will have final semi-finished products made of high elastic plastic.Most of the ingredients are organic substances, volatile, containing toxic, harmful and highly carcinogenic NOBS.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Industrial Power Nylon Flat Transmission Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords