Hydraulic Platform of Scaffolding for Repairing in Aerial Work from CNBM!

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Type: | Elevators | Place of Origin: | Shandong, China (Mainland) | Brand Name: | HAISHAN |

Model Number: | SC200/200 | Usage: | Construction elevator | Drive Type: | Rack & Pinion |

Elevator Type: | Goods Elevators | Condition: | New | Power Source: | Electric |

Sling Type: | Cable | Maximum Lifting Weight: | 2*2000KG | Maximum Lifting Height: | 150M |

Lift Speed: | 0-40m/min | Certification: | GOST,ISO | Warranty: | One year |

Packaging & Delivery

Packaging Details: | containers |

Delivery Detail: | 10--15days |

Main parameters of SC200/200 construction hoistThe SC200/200Construction Elevator is an external construction hoist with a three- drive rack-and-pinion mechanism. It has a rated loading capacity of 2 tons and a rated hoisting height of 150 meters. A simple alteration can change it into a single-cage construction elevator with a rated loading capacity of two tons. The SC200/200Construction Elevator is equipped with a state-patented safety device which can brake automatically in case of accidental fall. The driver element on top of the cage is safe and reliable and convenient for maintenance. The elevator with a maximum hoisting height of 300 meters is widely used for construction work such as industrial and civil construction, bridge construction, underground mining, large chimney construction and the shipping industry. It can be used for transporting materials or people vertically, as a permanent or half-permanent lift, or in places like storehouses and tall towers. | |

Mode | Rack-and-pinion Threee-drive Double-cage Construction Elevator |

Rated Loading Capacity | 2×2000 kg |

Passengers Loaded | 2×24 persons |

Rated Hoisting Speed | 34 m/min |

Rated Hoisting Height | 150 m (Goods-supply Height: 50m) |

Inside Dimension of Suspension Cage (L×W×H) | 3m ×1.3m ×2.4 m |

Power Consumption | 2×3×11(KVA) |

Motor Power | 11KW |

Weight of Standard Section | 140 kg |

Height of Standard Section | 1.508 m |

Type of Safety Device | SAJ30-1.2 50m |

Gross Weight | 10.56t |

- Q:Rack type lifting machine, rack press, rack lifting machine

- The rack press is the abbreviation of the press, hydraulic press and hydraulic press. The press refers to a kind of forming machine used for the pressure forming of the industrial products. The hydraulic cylinder is generally used, so it is also called the hydraulic press. In the building material industry, the press is the abbreviation of the brick press, and the press breaks up the dynamic brick machine and the automatic hydraulic brick machine.

- Q:Is there a good steel lifting machine, the crane always binding steel plate, the efficiency is not high?

- The easiest thing to do is to use a special hook for lifting iron (heavy lifting) and a manual magnetic sling under the wire rope.

- Q:What's the difference between a horizontal jack and a vertical jack?

- The outward difference is that the horizontal jack is big in size and the vertical jack is small in size,The utility model has the advantages that the operation is convenient, and the lifting capacity of the horizontal jack is large; the utility model is suitable for big carts. Vertical jack is easy to operate, suitable for small cars.

- Q:What are the points for attention in the course of transportation of double beam cranes?

- Component preparation, component preparation, including component counting, inspection and appearance modification, etc..(1) counting the components, including the type and quantity of the components, checking the order of the components according to the lifting sequence of the components, and determining the sequence of the loading of the components.(2) inspection component. Including size, geometry, the placement of parts and rings, and the stability of the location of the installation hole and the hole through the hole and so on.(3) check the weld seam of the steel structure. Including the weld size, appearance and connections whether the design and specifications meet the requirements, such as beyond the allowable error, should be taken effective measures to deal with.(4) appearance inspection and modification of components. Found defects and damage, such as cracks, pits, broken edge, weld length, height is not enough, weld ash or porosity, should be modified and after welding, to transport and use.

- Q:Classification of lifting tools

- Light and small lifting equipment mainly includes lifting tackle, spreader, Jack, electric hoist and ordinary winch. Most of them are small, light and easy to use. In addition to electric hoist, the vast majority of manpower driven, applicable to the work is not heavy occasions.

- Q:I want to know what the principle of magnetic suspension is. Why does it make magnetism disappear?! What is the structure like?!

- The working principle of the magnetic suspension is made by using the electromagnetic induction principle of Faraday. The internal use of the high performance permanent magnetic materials of neodymium borax, can produce a strong suction in the magnetic circuit, the magnetic field lines so that the jack handle turn at work or in a closed state; without external power supply, is a safe and energy saving, high efficiency of new lifting tools.

- Q:Do hardware or plastic factories have no need for cutting tools?

- Cutting tools must be needed. Hardware accessories refer to some small hardware, such as door locks, hinges, nuts and other mechanical components.

- Q:The permanent magnet use principle

- The utility model is a novel lifting tool with the advantages of safety, energy saving and high efficiency without external power supply.When Jack is working, Jack at the bottom of the lifting surface of the longitudinal magnetic pole, will hold firmly the iron workpiece material, and V shaped groove on the bottom surface, thus to ceiling plate shaped workpiece, also can absorb the hanging cylindrical workpiece. The jack of sheet thickness and area have strict requirements.

- Q:What important attention should be paid to large equipment?

- A fire extinguisher should be provided on the crane and rubber insulated mats shall be laid in the cab or the place of operation.

- Q:Do you know the manufacturer of small lifting equipment?

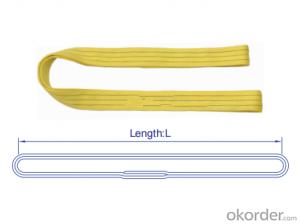

- Lifting equipment company operating mainly include: imports of high-end hand chain hoist, hoist, electric hoist, pneumatic hoist, permanent magnetic chuck, electronic hanging, lifting shackle, hardware tools, steel plate lifting clamp, sling, take-up binder, lifting sling, lifting tool and riot lifting chain etc..

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hydraulic Platform of Scaffolding for Repairing in Aerial Work from CNBM!

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords