2t Explosion-Proof manual pulley Chain Hoist

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Place of Origin: Hebei, China (Mainland)

Brand Name: CNBM

Model Number: HBSQ2T

Usage: Construction Hoist

Power Source: Hand Chain

Sling Type: Chain

Maximum Lifting Weight: 2 tons

Maximum Lifting Height: 2.5M

Lift Speed: same with pulling speed

Certification: CE,GS and ISO9001

Warranty: one year

After-sales Service Provided: No overseas service provided

Capacity: 2 tons

Standard lift height: 2.5M

Running test load: 2TONS

No.of falls of load chain: 2

Net weigth: 25kg

Color: cooper color

Description: Explosion-Proof chain hoist

Main Features

Superior rigidity makes the hoist dust-proof and water-pfoof;

Severe environment and work condition are acceptable;

Simple structure and few components

Adopt Janpanese FEC chain;

To greatly enhance the performance of the fatigue and wearresistance.

Limit protection adevice can avoid overload occerring;

Hook bolt can prevent the rigging accidently from slip;

Moter is equipped with thermal protection device;

limit contactors are set in the machine.

Picture

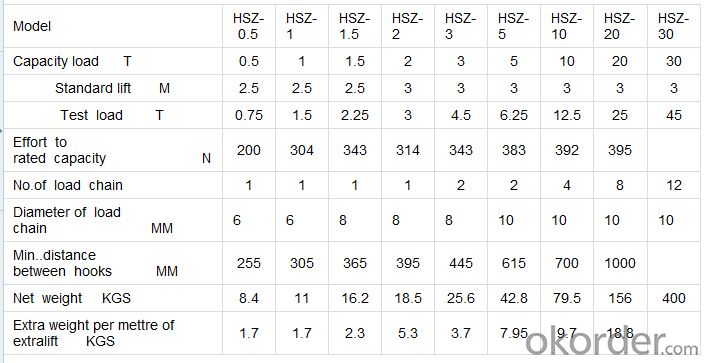

Parameter List

| Our Service |

| 1.We can make special sample according to the customer’s requirement. |

| 2. We have more than 60 professional technical team, provide best after-sales service |

| 3. Fast delivery time |

| 4. We have CE, ISO9001 and GS certification. |

FAQ

1.What’s your product range?

Electric Hoist: electric chain hoist , electric wire rope hoist, mini wire rope electric hoist, mini electric chain hoist.

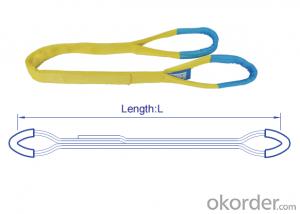

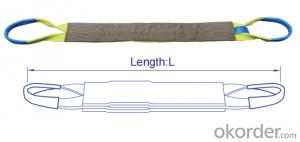

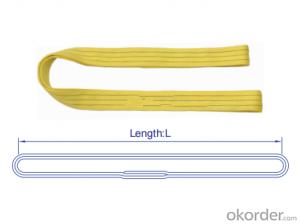

Manual Chain Hoist and Lever Hoist Chain , Trolley , Jack,Lifting Strap,Cable Pulley, hand pallet truck,etc.

2.When Can I get the quotation?

We usually quote within 24 hours after we get your inquiry . If you are very urgent to get the price , please tell us in your email so that we will regard your inquiry priority.

3.How can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality. If you need the samples, you need pay the express fee ,

4.What information should I let you know if I want to get a quotation?

1. Lifting capacity.

2. Lifting height.(hook center to ground)

3. Power supply: Voltage.

4. Span(rail center to rail center)

5. Working condition: which material to lift? temprature?

6. Would be better if you have drawings of your plant.

- Q:Which brand is better for imported rigging?

- CarlStahl set up Chinese branch in Hangzhou in 2006, mainly engaged in CarlStahl brand heavy duty crane, lifting fixture, spring balancer, hoist, crane beam, lift hook, rope, wire rope, tie, round sling hoisting products etc..

- Q:What's the sling for a movie?

- Now the movie also used the wire, but the rope is made by thin steel wire, so as not to betray. WIA, commonly known as wire.

- Q:What's the catch?

- The type of slings 1. slings are mainly metal slings and synthetic fiber slings in two main categories. 2. metal slings are mainly wire ropes, slings, chains, slings and so on. 3. synthetic fiber slings are mainly made of nylon, polypropylene, polyester, high-strength and high modulus polyethylene fiber for rope and belt slings.

- Q:What are the specifications for the length, length, and method of operation of the wire rope?

- Users need high quality steel wire rope, it should be long life and high quality stable and reliable wire rope.

- Q:20 tons sling rope, steel wire or chain?

- The strength of the steel wire rope can reach 2000-2500MPa, and is made by using cold drawn steel wire. The tensile strength is much higher than that of the chain, so that the weight of the sling can be reduced, the production efficiency can be higher, and the steel wire rope is preferred.

- Q:What are the dangerous sections of the crane hook?

- ) C -C section of the section is the thinnest part of the hook column in a sling tension, have pulled off the trend. Here the maximum tensile stress, it is also dangerous section.

- Q:What are the specifications for the rigging?

- Because the demand is more difficult to buy, to ask the producer of several wire rope, please note in the purchase, purchase invoice must indicate the name of wire rope, such as phosphate coated wire rope, prevent illegal infringement of their legitimate rights and interests of enterprises, in addition, patent products are generally in the rope on the outer packing of a patent spraying mark, warranty due the main technical indicators, such as the phosphating film type and film weight (have an important impact on the weight of phosphating film size, wear resistance and corrosion resistance of the service life of the wire rope, for reference only)

- Q:Requirements and matters needing attention in hoisting

- Hoisting tower tank by using rotary method or down method, wrist hinge at the bottom of the tower installation must have the ability level of the thrust generated resistance during lifting, the lifting process of the tower body around the ropes must be reliable, the tower height of the rotary position, slowly falling into the foundation, avoid accidents and deformation.

- Q:What are the precautions for rigging in hoisting works?

- The load weight shall not exceed the limit load of sling, sling should be used before the use of visual inspection, and according to the spreader lifting load check the working load limit, meet the requirements before use.

- Q:What are the connections and differences between hooks, slings, rings and heavy truck rings in cranes? What are the hoisting designs?

- A set of wire rope sling series: adhesive wire rope sling, wire rope sling, inserted Aluminum Alloy pressed wire rope sling, no joint wire rope hanger, wire rope sling, multifurcating nylon cord steel wire rope, plastic rope.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2t Explosion-Proof manual pulley Chain Hoist

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords