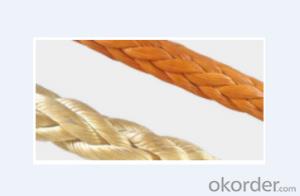

High Strength Mooring Rope,polyester, High Molecular Polythylene (UHMWPE).

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 0 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mooring Rope

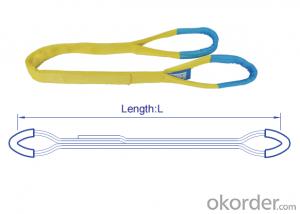

Production Scope: The structure of mooring rope can be divided into 3-strand, 6-strand, 8-strand and 12-strand. The raw material includes: polypropylene, polyester, nylon, High Molecular Polythylene (UHMWPE), aramid fibre and synthetic fibre. Diameter scope: Φ6mm ~ Φ140mm are available.

Characteristics of mooring rope: high tensile, low stretch, anti-friction, corrosion resistance, soft and smooth, easyto operate, etc. Mooring ropes are mainly used in shipping equipment, fishing industry, port operation, electric construction, oil exploration, national defense and sports goods, etc.

Achievements in scientific research:

In 1997, we drafted out the industrial standard for textile slings together with Beijing Hoisting Machinery Institute: JB/T8521-1997, which makes historic progress for the Chinese textile sling industry.

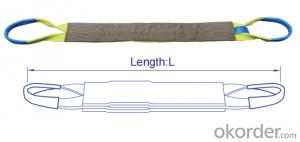

In 2007, we revised JB/T8521.1-2007 “Textile Sling – Safety - Part 1: Common use webbing sling” and JB/T 8521.2-2007 “Textile Sling - Safety - Part 2: Common use round sling”.

In 2009, we edited GB/T 23914.2-2009 “Road vehicle mounted fixtures – Safety – part 2: Synthetic ratchet strap assemblies”, participated in writing TB/T 3123.11-2009 “Rescue devices for railway accidents - part 11: high-performance textile sling”.

In 2014, we participated in writing GB/T 30667-2014 “Polyester and polyolefin dual Fiber rope” and GB/T 30668-2014 “8 strands, 12 strands and multiflament braided Ultra high molecular weight polyethylene fiber rope”.

- Q:What does the inspection of rigging involve?

- Phosphating coating of steel wire rope (Chinese patent), wire by Mn and Zn Mn phosphating treatment of steel wire, wear resistance and corrosion resistance of fully, are not easy to wear and corrosion fatigue life of the phosphating coating steel wire rope is the same structure of plain steel wire rope 3 times (laboratory comparable conditions), exceeding imports of steel wire rope, phosphating coating steel wire rope are fully replace all kinds of plain steel wire rope, also be replaced after plating the first pull layer thin zinc galvanized steel wire rope used (through salt spray test the corrosion resistance test), long service life, use lower cost, better quality stability and reliability.

- Q:What are the specifications for the length, length, and method of operation of the wire rope?

- The fatigue life is three times the same structure of plain steel wire rope, the highest value of contrast test has reached an alarming four times, can be verified by fatigue test, fatigue life ability if they have on their own to do comparative experiments, this test results the most credible, the service life of wire rope and the fatigue life is proportional to a long fatigue life use the same proportion of life extension, the use of lower cost, better stability.

- Q:20 tons sling rope, steel wire or chain?

- The strength of the steel wire rope can reach 2000-2500MPa, and is made by using cold drawn steel wire. The tensile strength is much higher than that of the chain, so that the weight of the sling can be reduced, the production efficiency can be higher, and the steel wire rope is preferred.

- Q:What are the selection principles for lifting cranes?

- To avoid the use of large lifting capacity of the crane lifting capacity of small parts, small crane overload lifting component, or choose not modified after the actual loading test of crane hoisting, shift or use the high cost of equipment.

- Q:Which sling manufacturer is more reliable?

- A variety of commonly used wire rope phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope, the use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, heavy corrosion environment optimization of hot galvanized wire rope double - phosphating coating.

- Q:Types of slings for slings

- Slings are mainly made of metal slings and synthetic fiber slings in two main categories.

- Q:Ceiling installation does not allow the use of air nails?

- (1) construction materials: common materials are as follows.Wood (different specifications of water, wood, water board), aluminum alloy (plate, profile), steel (steel, flat steel, steel plate), mainly as supporting components.Plastic, plexiglass plate, glass partition plate, outer decorative veneer and heat dissipating plate, copper plate and electrochemical aluminium plate as decorative component.Other accessories such as screws, nails, rivets, finished lamps, adhesives and so on.(2) construction tools: pliers, screwdrivers, hammers, saws, electric hammer, hand according to the curve, a ruler, paint etc..

- Q:Is rope sling good business and high profit?

- With an annual output of 1 million 800 thousand tons of steel China ranked first in the world, is the first world phosphating wire rope wire rope surface treatment inhibited fretting fatigue to prolong the useful life (fatigue life), business wire rope and rigging, ordinary product profit, if can be linked to the manganese phosphating coating of steel wire rope, the profit is very high

- Q:What tools are slings in lifting operations? What is the function of the slings?

- A sling is also called a jack rope, a pair of rope or rope buckle. Hoisting works are more used, such as tying equipment, hanging blocks, stabilizing winches and so on. The utility model has the advantages of good quality and large elasticity, but the rigidity is large, and the bending is not easy, and once the bend is not easy to recover. Slings made of wire ropes of hemp core are not easy to work under high temperature.

- Q:What are the connections and differences between hooks, slings, rings and heavy truck rings in cranes? What are the hoisting designs?

- Round nylon lifting rope series: no connecting nylon lifting rope, two button nylon lifting rope, multi nylon lifting rope and shipAnchor rope, rope, paper rope, lifting rope, all kinds of transformer braided rope.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Strength Mooring Rope,polyester, High Molecular Polythylene (UHMWPE).

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 0 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products