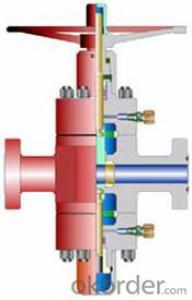

Hydraulic plate valve from okorder.com with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | China (Mainland) | Model Number: | Hydraulic plate valve | Brand Name: | sehm |

| Type: | Rotary Drilling Rig | Certification: | API | Usage: | Oil Well |

| Condition: | New | Warranty: | 1 | Voltage: | 2,000-15000 psi |

Specifications

Hydraulic plate valve

SS Gate Valve Handwheel Operated

1.Medium: water, oil, gas.

2.Certificate:API 6D,TS,CE.

Hydraulic plate valve

Applicable standards:Steel gate valves, API 600 / API 6D

Steel gate valves, ISO 10434 / ISO 14313

Steel valves, ASME B16.34

Face to face, ASME B16.10

Flanges end, ASME B16.5

Buttwelding ends, ASME B16.25

Inspection and test, API 598 / API 6D

Design description:

Full port design

OS&y,outside screw and yoke

BB,Bolted bonnet

Flexible wedge,fully guided

Choice of solid or split wedge

Renewable seat rings

Forged T-head Stem

Rising stem and non-rising handwheel

Flanged or buttwelding ends

Available with BG operator

Gate Valve Product Details

Design and Manufacture | ANSI B16.34,API600,API603,BS1414 |

Face to face(end to end) | ANSI B16.10,API6D |

Flanged connection | 2"~24" TO ANSIB16.5,22",26"~36" TO MSS-SP-44 to API 605 on Request |

Test and inspection | API 598,API6D |

Butt welded end | ANSI B16.5 |

A. Anti-friction ball thrust bearing: Reduces friction between mating parts to ensure smooth operation

B. Grub screw: Secures yoke nut in the bonnet

C. Grease nipple: Supplies lubricant to the mating parts

Manufacturing Process

STANDAR3DISATION

All products are manufactured in accordance with the guidelines of International Standard accepted all over the world such as Manufacturers Standardisation Society (MSS), American Petroleum Institute (API), American Society of Mechanical Engineers (ASME), British Standard (BS), Bureau of Indian Standard (BIS).

PROCURMENT OF RAW MATERIAL

In the manufacturing process we require Castings of different grades, Stainless steel Bars, forgings, hardware, gaskets & paints. All raw material purchase from the reputed & genuine concerned supplier.

QUALITY CONTROL

All raw materials are checked by our Quality Assurance Department prior to manufacturing process. For an example, when we received the castings, it is checked visually and dimensionally for machining tolerance. We also check the foundry chemical Test Certificate and physical test certificate, compared to suitable international standard and passed to machining shop for the further process, if it is rejected it is send back to the supplier.

MACHINING

The raw material issued to the machine shop for the machining, is machined strictly as per the relevant drawings.

INPROCESS TESTING

If it is found OK dimensionally the valve body and bonnet are sent for the hydro testing. All internal parts such as seat, disc, stem are measured by the Vernier Caliper or micrometer, if it is found O K than pass to assembly section for the further assembly. All the valve body and bonnet are tested on the motorized pump or hand pump as per the relevant standard. The theory being, when the body or the bonnet is under pressure there should not be any leakage or drops of the testing fluid from any portion of the castings. If any leakage observed, it is rejected and sent back to the foundries.

ASSEMBLY

The body and bonnet, which are Hydrostatically O K, are sent to assembly section, duly handled with care to avoid the scratches on the machined surfaces. In the assembly section body and bonnet are drilled on drill machine with the help of jigs & fixtures for uniformity and interchangeability.

LAPPING

In metal to metal seated valves, seat & disc/plug are lapped by Rough Lapping Paste to smoothen the seating surface and than lapped with very fine grade lapping paste for the proper sealing of disc & seat surface, to ensure zero leakage.

TESTING

After assembly of new complete valve is sent for Hydrostatic Testing. If no leakage is found as per the relevant standard, it is sent to finishing section.

FINISING/PAINTING & PACKING

The valve body and bonnet is debarred and finished by flexible shaft grinders for better appearance. One coat of corrosion resistance primer (red oxide) is sprayed, and colored as per the codes, twice for superior surface look.

Valves are packed either in wooden boxes or Gunny bags duly protected by ends enclosures and soft material to avoid any damages during transit.

MainFeatures :

Body & Bonnet made from high quality casting with liberal sections. The castings are precision machined for high performance

Bi-Directional Shut-Off

Die moulded Graphite (Grafoil) Packing Rings, controlled clearance between stem, gland and bonnet bushing for guaranteed low emissions and also suitable for higher temperature.

Deep stuffing box is providing for tightness and maximum long packing life.

Swinging Eye Bolts facilitate easy access to the stuffing box.

Back seating feature facilitates repacking of the stuffing box on line with the valve in fully open position.

Seat Ring Screwed in to the body are replaceable type. Seal welded type Seat Ring & Integral Seat cab also be offered on special request.

Stellited Disc, Seat Ring & Back Seat can also be offered on special request.

Higher Pressure & Higher Size Valves are provided with Thrust Bearings and also with Gear drive arrangements.

In built wear life for long duration of service.

- Q:so do v-6 engines mean 6 cylinders right?, but what are valves? sometimes they are like double the cylinders (12 valve v6). what do they do, and cars that have like 2.5L does that mean how much fuel is injected and does more mean more power?on a side note, what kind of engine is the evo x? is it 4 cylinder? but has really good technology in it and is that how it has such high bhp?also if anyone knows, i kinda know what torque is but can someone explain in laymen terms? does more=better?

- OK well first, cc stands for cubic centimeters, and they measure the displacement within the cylinder of your engine. Basically, the more cc's the bigger the engine. HP is horsepower and generally the more cc's the more horsepower, altho that is not always true, especially if you turbocharge or supercharge and engine. Also, some manufacturers are able to engineer their engines better than others, thus producing more horsepower out of a smaller (less cc) engine. Finally, valves are like little doors in your cylinder. They open and let in the air and fuel, the engine burns the fuel, and then other ones open and let out the exhaust. Some manufacturers put 2 or 3 or 4 of these doors in each cylinder, with the intention of getting the gas in and exhaust out faster, thus producing more horsepower in some applications. A 16 valve engine will generally be a 4 cylinder engine with 4 valves per cylinder, it is a common engine setup. If you still have questions, wikipedia is your friend.

- Q:What is a valve adjustment? I wanted to do one on my 1994 Honda civic ex cuz my friends told me I should do one but I wanted to know howmuch will it cost? And what will it do to my car in performance and gas consumption? My car right now has 155k miles.

- Leave it alone. Besides at 155k a Civic is junk not worth spending money on.

- Q:Does anybody know what the valve lash specs are on a 1986 chevy sprint 1.0L carbureted?

- 1986 Chevy Sprint

- Q:Hi. I am planning to install new kitchen faucet and noticed that there are two shut off valves under the sink. One of them is badly rusted and needs to be replaced. I noticed that it is connected to three pipes (one of which is kitchen faucet). The other is clearly water coming in. What is the third one connected to wall? Also how should I go about replacing this? Anything that I should be careful of? Thank you.Here's picture of shutoff valve.

- can't get your picture to load. is it the hot? is there a dishwasher a wee bit away from sink? is there something water related on the other side of the wall?

- Q:Im replacing the valve stem seals and i dont know how to remove the springs and with the valve compressor wont fit in the engine

- Do NOT do what banit said, if you did his technique once you remove the keepers the valve would drop to the bottom of the cylinder and require a tear down. You must get the piston be at top dead center on the cylinder you intend on removing the valve springs from and you cannot do any other valves besides the ones on the cylinder you brought to top dead center. You can take the rocker arm off the top and take the push rod out then when at top dead center using a spring compressor you can take the keepers out, or if you do not have a spring compressor (proceed at your own risk) you can get an oversized socket and a dead blow hammer and place the socket over the top of the valve spring with the octagonal side towards the spring and give it a decent hit, but be aware the keepers will pop out and you may lose them if you are not careful.

- Q:after my hot water tank shuts off about 1/4 cup of water comes out therelief valve. i changed the relief valve. the tank is 6 months old

- Do you mean the heating (burner or heating coils) shuts off. If that is the case then you may need an expansion tank. If there is a reverse flow valve at your meter (most locations now require this feature to prevent back flow of water to the main line.) the pressure in your system can build up higher than normal when the hot water tank is heating. Most systems have a small expansion tank installed near the hot water heater to deal with this problem.

- Q:How hard and expensive is it to replace a pvc valve , hose, filter on 1991 Dodge Caravan 4 cylinder

- THE GUY ABOVE TOTALLY MISSED IT. IT IS VERY SIMPLE TO REPLACE AND SHOULD COST LESS THAN $25.00.

- Q:We've got a one-handled faucet for the tub/shower and it has that pressure-balancing mechanism. We have it set, I think, so that we can take the hottest showers possible, because our water heater lacks enthusiasm. However, when I want to draw a bath for the baby, I need it to be lukewarm - and I have to turn it almost OFF to get the water to be even tepid. I can't get cold water out unless it's only trickling. As far as I can tell, our cold water pressure isn't different from the hot (bathroom faucets are 2 handles and H C seem to be about the same pressure). Is there a way to adjust the valve in the shower so I can get both the hottest possible, and the coldest possible water at full pressure?

- the new single handle tub and shower valves all come with a scald guard mechanism.(its code so kids cant turn on the hot and burn themselves). take the handle off and mess with it. it will be grey or black with a bunch of grooves on the outside. keep adjusting it till it satisfies you.

- Q:I've been playing french horn in school for about five years, and I'm not exceptional by any means! But I love the instrument. Our school district bought a french horn a few years ago when we didn't have enough french horns for players. The almost new Holton has great tone. But unfortunately it fell into ignorant hands and has been neglected for two years. I just received the instrument and cleaned it up and got it back up to snuff, except for the valves. I can't get them to run smoothly!! They act all gummed up. I've put oil in the top and bottom of the valve, and I've dropped a couple drops in the tubes down onto the valves, but they're still gummed up! Do I need to use more oil?? Or what? Any suggestions?

- Sounds like your oiling correctly but you need to get the dried oil out, that's the gum your feeling. One way is to have the school send it to the repair shop, its not your horn so don't spend any money on it. Another way is to flush them out with a thin valve oil. Where can you buy a quart of valve oil? Walmart and Kmart has it but not labeled as valve oil. Look for Lantern oil , the stuff used in oil lamps, it is very cheap and many of the valve oils are made of the same stuff. Take out all the crooks on the instrument and flood the valve with the lamp oil, this should flush out the gum. After you have dumped the lamp oil re-oil the way you have been. (Lamp oil is not dangerous, it burns if you hold a match to it but that is about it, you can also use charcoal lighter)

- Q:she 13 and shes always sleeping what is a leaky valve there not telling me enough for me to understand and im a nurse tech im scared for her

- I'm okorder /

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hydraulic plate valve from okorder.com with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords