HR Carbon etc Hot Rolled Steel with Standard Q235 Q345 SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot rolled steel Description:

Rolled to its final dimensions while it’s hot enough to scale, our hot-rolled steel is an amalgamation of the various qualities of steel. It can be in the form of plates, sheets and coils. Our hot rolled steel sheets and coils are applied to wide range of uses such as automobile, electrical appliance, machinery manufacturing, container manufacturing, shipbuilding bridge, pipeline, and receive high acclaim from our customers for its excellent quality.

Quick Details

Standard:AISI, ASTM, BS, DIN, GB, JIS

Grade:hot rolled

Thickness:2mm-60mm

Model number:Q195-Q235-Q345

Type:steel coil

Technique:Hot Rolled

Surface Treatment:Can provide galvanized

Application:Flange Plate

Special Use:Wear Resistant Steel

Width:1000-1800mm

Length:Coil or cliens requirements

Packaging & Delivery

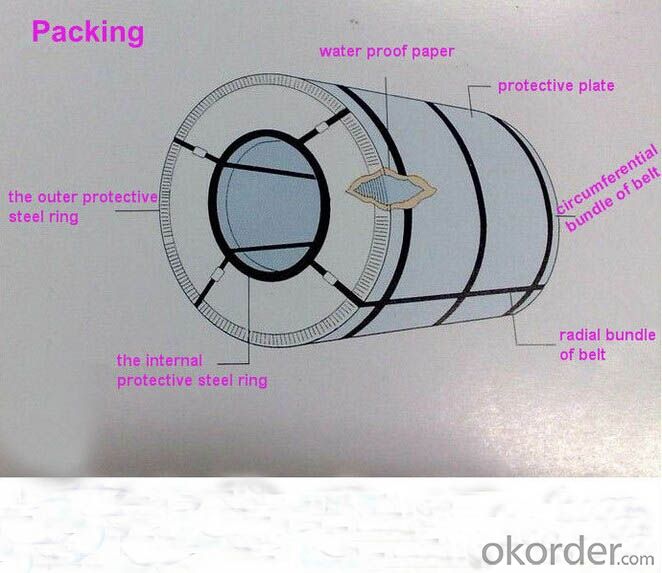

Packaging:standard sea export packing, or we can also package according to the customers' requirments

Delivery Detail:about 20 working days

Specifications

| Commodity | Hot rolled steel Coil |

| Thickness | 2.0-60mm |

| Width | 1000-1800mm |

| Material | Q195-Q235-Q345 |

| One Coil weight | About 20 tons |

| Surface treatment | Oiled or unoiled as the requirement |

| Packing | Seaworthy packing, each coil packed hot rolled steel strip, put 1 or more coils in one pallet, then packed with plastic membrane, then packed with pp bags (inside the bag is plastic membrane), last protect the corner with hot rolled steel strip. |

| Supply ability | 6000 ton per month |

| Delivery time | 10-25 days |

| Application | Roof, outer walls, ovens, lined plastic window, light steel keel. |

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q:I want to know if it is possible to make regular steel stainless.From what I understand stainless consist of chromium about 10 percent I think.Any way I'm wondering if properties can be added in a process or can this only be possible during actual manufacturing of the steel.And I'm not talking about chrome like stainless steel that's not to shiny.

- Worth very little as far as I'm concerned. It has a very poor co efficient of heat, is hard to lubricate to keep the food from sticking and will develop a hot spot easily. My preference is a good quality cast iron, it is heavy but conducts heat well and spreads it evenly. Stainless with copper bottoms is marginal for boiling water but it does clean easily. There are several alloys on the market that are usable as cook ware. Aluminum is worse than stainless. Of the pure metals, copper is the best conductor of heat, cast iron is my choice, spun steel does work. Hope this helps. Never wash cast iron cookware with soap and water.

- Q:Is it faster to smith steel or mithril in Rinescape assuming I'm going to mine everything myself?Mining level: 76Smithing level: 55

- steel, it will take you way to long to mine mithril ore, and all the coal. also if you make steel plate bodies they actually sell becuase people use it to make steel titian pouches

- Q:We have a stain from a pot or bowl in our new expensive stainless steel sink. It looks like a water mark that happens when you leave a glass on a table without a coaster. It's a mark in the shape of the bowl or pot that was there. We left it there overnight:( It's not rust either. Help!

- The best product I have ever come across is Barkeeper's Friend. I use the liquid version rather than powdered version. It is a soft soft abrasive scrub designed for stainless steel. I original found it to use it on all my All Clad pots and pans to keep them beautiful and shining. I also have a stainless kitchen now, sink, stove and fridge...and I use Barkeepers on everything. It is fantastic. If you don't want to go out and find Barkeepers tonight, you can get a similar affect using baking soda mixed with dish soap. Make a good paste to gently rub on stains. Be sure to rinse the stainless steel surface thoroughly, and towel dry. If the stains still remain you can try vinegar. Remember to thoroughly rinse and towel dry. But tomorrow go out and get a bottle of BarKeeper's Friend...you will never regret it. UPDATE: just saw a few other answers, DO Not use steel wool (SOS pads) you will scratch the heck out of the finish and you will not be able to fix it.

- Q:How are steel tape measures installed?

- That's the tape measure. There's a small card with no card in the middle of the screw! So it can't be retracted automatically! The solution is to wrap the open tape to the end!

- Q:Hi, I need to know why stainless steel is rust proof please tell me its for my science project. :)

- Why doesn't stainless steel rust? Nancy Avery, New London, Conn. Metallurgical engineer Michael L. Free of the University of Utah offers this explanation: Stainless steel remains stainless, or does not rust, because of the interaction between its alloying elements and the environment. Stainless steel contains iron, chromium, manganese, silicon, carbon and, in many cases, significant amounts of nickel and molybdenum. These elements react with oxygen from water and air to form a very thin, stable film that consists of such corrosion products as metal oxides and hydroxides.

- Q:What are the different types of steel coil surface finishes?

- There are several different types of steel coil surface finishes available, each with its own unique characteristics and applications. Some of the most common types include: 1. Hot rolled: This finish is achieved by rolling the steel at a high temperature, which results in a rough and textured surface. Hot rolled steel coils are commonly used in applications where aesthetics are not a priority, such as structural or industrial projects. 2. Cold rolled: In contrast to hot rolled steel, cold rolled steel coils are processed at lower temperatures, resulting in a smoother and more refined surface. This finish is ideal for applications where a clean and polished appearance is desired, such as automotive parts, appliances, and furniture. 3. Galvanized: Galvanized steel coils are coated with a layer of zinc to protect them from corrosion. This finish provides excellent resistance to rust and can be used in a variety of outdoor applications, including roofing, fencing, and signage. 4. Stainless steel: Stainless steel coils have a unique finish that is resistant to corrosion, staining, and rust. This makes them highly versatile and suitable for a wide range of applications, including kitchen appliances, medical equipment, and architectural projects. 5. Coated: Coated steel coils are treated with a protective layer of paint or other coatings to enhance their durability and aesthetic appeal. This finish is commonly used in the construction industry for applications such as roofing, siding, and garage doors. 6. Pre-painted: Pre-painted steel coils are coated with a layer of paint or resin before they are formed into the final product. This finish offers a wide range of colors and finishes, making it popular for applications such as building cladding, appliances, and automotive parts. Overall, the choice of steel coil surface finish depends on the specific requirements of the project, including aesthetics, corrosion resistance, and durability. Each finish has its own advantages and disadvantages, and it is important to consider these factors when selecting the appropriate type of steel coil surface finish for a particular application.

- Q:How are steel coils coated for corrosion resistance?

- Steel coils are typically coated for corrosion resistance using various methods such as hot-dip galvanizing, electroplating, or applying a protective layer of paint or powder coating.

- Q:What are the safety precautions when working with steel coils?

- When working with steel coils, it is important to follow several safety precautions. Firstly, workers should wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toe boots to protect themselves from potential injuries. Additionally, they should ensure that the work area is well-lit and free from any trip hazards. Proper lifting techniques should be used to prevent strains or sprains, and workers should be trained on how to safely operate any machinery or equipment involved in handling the coils. Regular inspections of the coils, checking for any defects or damages, should also be conducted to avoid accidents. Lastly, workers should be aware of the potential hazards associated with working with steel coils, such as sharp edges, pinching points, and the risk of heavy objects falling, and take necessary precautions to minimize these risks.

- Q:What is steel made of? What are the elements other than iron?

- mainly steel made of Iron and carbon and treated in a proper process to become hard you can add some kind of other elements to get your desired proparty as Chromium,, nickle.. Cupper,, Berelyium,, Vanadium

- Q:How are steel coils inspected for surface cleanliness?

- Steel coils are inspected for surface cleanliness through various methods such as visual inspection, magnetic particle testing, and ultrasonic testing. These techniques help identify and remove any contaminants or defects that may be present on the surface of the steel coils.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HR Carbon etc Hot Rolled Steel with Standard Q235 Q345 SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords