Hopper Bottom Galvanized Grain Steel Silo Used for Storing Rice

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 500000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

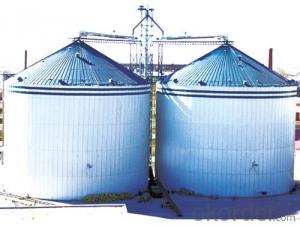

Hopper Bottom Galvanized Grain Steel Silo Used for Storing Rice

Specifications

1,galvanized grain steel silo for sale

2,high quality and best price steel silos

3,hopper bottom steel silos used for storing

assembly corrugated hot-dip galvanizing hopper bottom steel silos used for grain storage with best quality and price and 50-1250tons capacity for sales

Features

Hopper bottom steel silo are famous for its automatic discharging process.

The grain inside silos could unload automatically due to gravity, and very efficient;

The steel legs are made of H beam which have good quality and bearing.

2 kinds of angle-45 degree and 60 degree, among which the 60 degree conical-bottom is usually used to store larger pellet and powdered materials of high viscosity.

Hot dip galvanized steel sheets, 275g/m2 coating galvanizing.

Bolt and screw connected, assembly and easy maintenance.

Application

Our bolted steel silo is used to store grain, seed, feed, cement, coal and other granular or powdered materials. Popular uses for our product include, Temporary Transit, Raw Material, and Grain warehouses. Current applications of the Bolted Steel Silo is to provide efficient and affordable storage solutions for grain warehousing, alcohol plant, flourmill, oil mill, starch factory, feed mill, malt factory, distilleries, seaport, farm, and grain-processing centers, etc.(Grain including: Wheat /corn /soybean /sorghum /buckwheat /cereal /paddy /millet /bran /rice /peas /beans /rapeseeds /beet seeds /peanut /rye)

Some advantages of our product:

1. Lower basic cost with lightweight, low request for foundation, low consumption of steel.

2. High degree of standardization. We can produce the standard components which can be installed on-the-spot.

3. Simple, easy and efficient to install within a short amount of time due to superior component design which are connected by standard bolts.

4. Easy to understand . The bolted silo is equipped with relevant accessories, such as: conveyor, ventilation, drying and monitoring devices, etc. to ensure the quality and safety of the material stored in the silo.

5. Easy to maintain. As the parts of the silo are connected by standard bolts, so it is easy to remove or repair it.

6. Low cost and long tenure of use. The cost of bolted silo is just 35%-50% of the cement silo with the same specification; and its life span can reach 30 years.

7, Hopper bottom silo advantage is can natural flow, but it is capacity limited, capacity no more than 1250tons.

Structure

1. The Silo Body

Include the wall plate, column, manhole, roof ladders and so on.

(1) The wall plate

Our steel is hot galvanized, which makes it durable and weather resistant. Our advanced bolts with spherical washer and the resisting-worn rubber are used to ensure the tightness

and using period.

(2) Column

The column, made by the Z-bar, is used to reinforce the silo body. It is connected by junction panels.

(3) Manhole and Roof Ladders

There are inspection door and ladders inside and outside the silo body. It is convenient and accessible for any maintenance work.

2. Roof

Roof is made up of radiated beam, roof cover board, tension ring, ventilator scoop, roof cap, etc.

The space age construction technology, which is adopted in the design of the silo framework, can ensure the stability of silo under the large span. There is a guardrail around the silo eaves and there is also a manhole on top of the roof.

3. Hopper bottom

Steel leg, laces for steel leg, ventilation net pipe

Pictures

- Q:I would like to use explosives of some sort. I've had suggestions of drilling some pipe bombs in around the base. Any suggestions?

- You need to understand both the explosive and the structure involved. The fact that you talk about pipe bombs' demonstrates that you haven't a clue about how demolition explosives are supposed to work. Play around with setting them off remotely in a hole if you must, but don't try to work with them in the real world.

- Q:Define the term homogeneous product. Explain why price taking occurs when products are homogeneous. For which of the following products, if any, would the seller likely be a price taker? Explain your answer: (a) 1992 Ford Escort; (b) 100 shares of General Motors common stock; (c) Panasonic 19-inch color TV; (d) an apartment full of furniture; (e) a silo full of corn.

- what is price taker or taking

- Q:so we have this silo thingy. ya know, like a building that's an octagon. it has 2 floors. it's not too big.i want to create a place me and my friends can hang out. what kind of stuff should i put in there? what kind of things should i buy? should i have a theme? what should it be?i want it to be fun and entertaining. i don't want too many soft things {blankets, chairs with cushions, etc} because of bugs. how can i keep them out by the way?how can i light it since there's no electricity? what things should i put in there to keep us entertained? any GOOD help is appreciated! thanks!!

- Dude okay first of all, where is this place!?!?!?! Haha second, make it kind of like a mod theme. Like futuristic and present day @ the same time things.

- Q:A silo contains a mixture of lentils and corn. If 50 bushels of lentils were added to this mixture, there would be twice as many bushels of lentils as bushels of corn. If 150 bushels of corn were added to the original mixture, there would be the same amount of corn as lentils. How many bushels of each are in the silo?As the answer the book gets:There are 350 bushels of lentils and 200 bushels of corn in the silo.How do I get the equations though?tyyyyy

- Missing a word in the first problem. Is it difference? y - x = 3 The first problem is just a matter of translating words into mathematical symbols. Call the smaller number x and the larger number y. twice 2 * the larger number y is = 36 more than 36 + three times 3 * the smaller number x 2*y = 36 + 3*x In the second problem, you also need to know the formulas for perimeter and area of a rectangle. Call the width x and the length y. 2x + 2y = 64 y = 14 + x Find x*y

- Q:I just want to know!

- no, but i hear their leader likes to play w/ terran and the silos.

- Q:Get cheap

- near the beach of Silo, its cheap there

- Q:I heard Putin (Russia) government has great influence from silo wiki? what actually is that?

- Could be a code name for something secret that the Russians don't want people to know about. Well, it could mean that there's a nuclear silo called wiki and that there are some very powerful people in the silo, which would likely double up as a nuclear shetler and exert a great deal of influence onto Moscow, perhaps.

- Q:Just curious

- Suppose you were a bean farmer. After the harvest you would store all you beans in a large silo. Would it really matter to you how many beans were in the silo? If you lost one or two beans would that be a concern? People who obsess over inconsequential details are often referred to as BEANCOUNTERS. As others have said, accountants have a reputation for being overly concerned with details that matter only to themselves which makes them the chief example of BEANCOUNTERS.

- Q:Please don't give me an answerI just want to know how to work it out!An empty silo is to be filled at a constant rate of 2500 kilograms per hour. How many more hours will it take to fill the silo?**It will take 20 000 kg to fill.

- 2500 kilograms are filled in 1 hour. 1 kilogram is filled in 1/2500 hours. Therefore, 20000 kilograms are filled in 1/2500*20000 hours. =20000/2500 hours. =8 hours. ANSWER-The empty silo will be filled in 8 hours.

- Q:good for 20 tons minimum of corn for feedmill. Philippine peso costing is requested. Location is in Davao del Norte. Include names and addresses of suppliers/ contractors, if possible email too.

- Contact a local manufacturer or distributor. The biggest cost will be getting it to your site and getting it put up.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hopper Bottom Galvanized Grain Steel Silo Used for Storing Rice

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 500000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords