HLS120 Environmentally Friendly Ready Mix Concrete Batch Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A wide range of Containerized Concrete Batching Plants which have production capacity from 60m³/h to 200m³/h with one mixer. In addition to this, the capacity can be 120m³/h, 160m³/h, 180m³/h, 300m³/h and 400m³/h in Containerized Concrete Batching Plants with double mixers on the same chassis.

These Containerized Concrete Batching Plants can be used to stir all types of concrete including dry hard concrete, fluid concrete, light aggregate concrete, and others. They are mostly preferred for high capacity concrete production requirements, for special projects and for the projects which will take a long time in the same location, such as large scale building construction, water power plants, airports, docks and bridges, as well as the large and medium scale precast concrete plants, ready-mix concrete plants and pipe piles production factories.

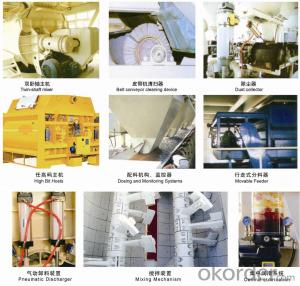

1. The host of the concrete mixing plant uses twin-shaft mixer and can produce many kinds of high-quality concrete, such as dry hard concrete and plastic concrete and others.

2. The aggregate is sent to the storage bins on the ground by the loading machine, and then is transferred to the aggregate storage buckets separately by belt conveyors and distributors;

3. Accumulative or separate metering methods can be used to measure aggregate through electronic weighing apparatus;

4. Capacity and quality of cement storage silos, and/or fly ash coal storage silos can be customized; powder materials are fed to weighing hoppers by screw conveyors for individual or cumulative measurement;

5. Water and the liquid additives are pumped to weighing hoppers for independent measurement;

6. Components and parts of famous domestic and international brands are incorporated to ensure the reliability and high production efficiency at sites:

(1) Main transmission is fitted with an Italian Bonfiglioli Brand planet gear speed reducer, which ensures high transmission efficiency, stable performance and has a strong resistance to overload.

(2) Air cylinder uses a Hymig or AIRTAC product which can be used for a long time with stable performance.

(3) The pneumatic components are from YSC or AIRTAC, which provide reliable performance with low levels of malfunction.

(4) The air compressor is a branded American Liebao product with a large air displacement capacity and steady operation.

(5) Schneider electric parts and Siemens PLC are adopted in our concrete mixing plant to ensure the reliable performance and high production efficiency.

7. Automatic production control system and feeding control system:

(1) The production control system adopts computer control and electronic scale measurement;

(2) The control system owns the functions of screen display, automatic free-fall correction, and equalize the sand containing water rate (The testing apparatus of sand containing water rate should be bought separately); manual are automatic control are both available during the mixing process;

(3) Equipped with the print system and four points monitor system to realize the central control and overall management of the whole plant, and the aggregate charging part is controlled by separated operator.

PRODUCT DETAILS:

1. Superior mixing performance

(1) Twin-shaft mixing host produce many kinds of high-quality concrete in high efficiency, such as dry hard concrete and plastic concrete and others, in high efficiency.

(2) It adopts an Italian Bonfiglioli Brand planet gear speed reducer which has the features of small volume, high efficiency and reliable performance;

(3) Its scale board and blades are made of wear-resistant casting alloys, ensuring high mixing efficiency and increasing durability;

(4) The shaft end is airproof and is completely sealed. The unique shaft-end bearing and seal design can greatly increase its durability;

(5) Overweight design provides excellent vibration absorption;

(6) Discharging door is controlled by a hydraulic pressure oil pump, equipped with three-point stop and manual open device;

(7) Centralized lubrication system adopts a 380V electric motor, which can pump the lubricate oil to the axes quickly.

2. Advanced and reliable electric control system

(1) The whole plant is controlled by computer or Siemens PLC.

(2) Manual control and automatic control systems are both available.

(3) Dynamic display panels and human-machine interface are used for the overall management and supervision of the plant functions and operations. Detailed operating information can be displayed, stored, output and printed.

(4) It has an automatic difference compensation function and can finish reserving tank production automatically.

(5) The control system, which is composed of an industrial touch screen and microcomputer, carries out the production control function to ensure reliability. When the microcomputer fails to control the normal production of the mixing plant, the industrial touchscreen can perform the function to ensure normal production, thus achieving the effect of double control by one machine.

3. Comfortable operating room

(1) Our operating room, which is totally enclosed, is fitted with an air conditioner in order to provide a working conducive environment.

4. Reliable and precise aggregate batching machine works automatically

(1) Pneumatic Batching Series: Pneumatic aggregate batching machine has a horizontal structure and adopts a cylindrical opening batching mode to batch materials. Three or four aggregate bins are available. (2) Electronic scales are used to carry out accumulative measurement or independent measurements. A programmed batching controller controls the process automatically. It has the features of high batching accuracy, short batching period and easy operation, etc.

(3) Motor Batching Series: Motorized aggregate batching machine is of a straight structure and can have two or three bins. Batching of materials is done through a belt conveyor. Electronic scales are used to carry out the function of accumulative measurement. The process is controlled automatically using a programmed batching controller. It has the characteristics of high batching accuracy, strong adaptability, easy operation and reliable performance, etc.

SPECIFICATIONS:

Model | HLS120 | |

Production capacity (m3/h) | 120 | |

Concrete mixer | Model | JS2000 |

Power (kW) | 2×37 | |

Output capacity (m3) | 2 | |

Aggregate size (gravel/cobble stone) (mm) | ≤60/80 | |

Batch bin | Capacity (m3) | 20 |

Belt conveyor deliverability (t/h) | 600 | |

Weighing scope and measuring accuracy | Aggregate (kg) | 4×(2000±2%) |

Cement (kg) | 1000±1% | |

Fly ash (kg) | 400±1% | |

Water (kg) | 400±1% | |

Admixture (kg) | 40±1% | |

Discharging height (m) | 3.8 | |

- Q:WHY DO THE VIRUSES USE THE CELL MACHINERY OF A LIVING CELL TO MULTIPLY?

- They do this because they have no reproductive cell machinery of their own to do this. This is why they are debated as being non living entities. Their DNA or RNA (never both) is programmed to hijack the hosts DNA to make more viruses

- Q:I'll concede that Micro Machines have been proven. We've all seen the commercial with that fast-talking guy, but nobody has ever been able to talk slowly enough to prove Macro Machines to me.

- Because school shop created bookshelves, mail boxes, wooden trays coffee tables, spoon racks, gun racks and recipe holders are wonderful things to treasure. I am the proud owner of all these items. Sons, husband and father were all latheists. :) EDIT: Turtle, my Bear tells me I didn't understand your question at all. He tried to explain it to me. ??? This blonde Chicken has to stick with the school work shop spoon racks and recipe holders. :O

- Q:i own my own construction and landscaping company and have 7 years experience in an excavator bulldozer and other pieces of heavy machinery.

- If you can afford to ship it and pay your airfare then you are wanted

- Q:What is mechanical engineering?

- Introduction to mechanical engineering related science and technology as the theoretical basis, combining the technical experience in the production practice, study and solve in the application of discipline development, design, manufacture, installation, use and repair all kinds of machinery in all theoretical and practical problems. Machinery is one of the five essential elements of production and service in modern society (human, capital, energy, material and machinery), and is involved in the production of energy and materials.

- Q:i need names of people/companies who maufacture machines for pulses

- Dear Shweta, Please go to Google search, enter pulses grading machine manufacturers in India , click on enter. You will opened with hundreds of manufacturers list, who are manufacturing all machinery's related to pulses, like pulse grading, dehusking, cleaning, packing and even oil extraction plants. Good luck.

- Q:I'm pretty disturbed about this whole deal. So she doesn't have certain female components.. does that make her a man? Is that why she ran so much faster than everyone else in Berlin? Are men really that much faster than women? Do you think she knew?

- Face it, estrogen's only redeeming value is to make a woman look supple and moist and give her reproductive capabilities. It's a real drag otherwise. So, she was born a hermaphrodite, so what, the more power to her. More women should be so lucky. Too many people in the world anyway especially in Africa where she comes from. Obviously, she has a lot more testosterone floating through her veins than estrogen. Just because she doesn't have octo-mom capabilities, everyone is on her case. She just happens to have all the ingredients to be what she is and that is a no-hands down world class champion. I suppose they could try to clone her LOL!!!!

- Q:I want to take it with me on a trip I'm going on with a group.(Halo 2 splitscreen action)However, the parents disagree, so how do I smuggle it in my bag?So far I only have a small suitcase of clothes for bags.Any ideas?

- take the 360 for some halo 3 splitscreen action

- Q:What would be more delicate? A VCR's tape head or a DVD's lens? I don't mean the more older they are, the more fragile or delicate they would be but as in if they were manufactured in the same year, date and even the same second, what would be more delicated.PS; You might want to regard this question as a vote or an actual fact.

- In my opinion, the rotary video head is more delicate that the lens. First, it does come in contact with the tape, so can get damaged. Cleaning it improperly can damage it. A DVD lens does not contact the media in normal operation, and are pretty foolproof to clean.

- Q:I am restoring an older , but good piece of machinery. It sat for many years, so it's really really dirty and showing some rust and paint wear. I do not want to wash it and get water all over it so it starts rusting the gearing, and tooling surfaces. What do you recommend to start getting this beast clean, so I can work on it without getting really, really dirty? Is there a spray or should I use something like ...WD-40? How about the chemical RESTORE they show on the $19.95 TV Ads??? Used to restore the faded paint on a car or clean the headlight lens from oxidation??

- There are degreaser products, but those are fairly aggressive and intended for really gummy congealed lubricant removal. WD-40, while less aggressive, is still a pretty good solvent as well as a light lubricant. If you need a lot of it, they sell it in 1 gallon cans (and probably larger sizes for industrial use), and they have pump sprayers to use with that size. I think a product for use on headlights or faded paint would be more of a polish than a degreaser, so that would not be appropriate unless you're trying to clean up a plastic viewing window or some such plastic guard, shield, etc.

- Q:i want to find some suppliers who can provide corn germ oil machine and macaroni machine

- corn oil; do you mean bio diesel or other? macaroni machine?

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HLS120 Environmentally Friendly Ready Mix Concrete Batch Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords