High Temperature Graphite Coated Fiberglass Fabric Heat Resistant Glass Cloth

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

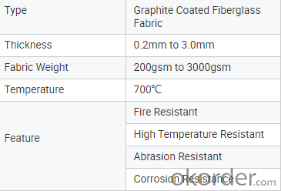

Description: Graphite coated fiberglass Fabric is a unique cloth constructed from base material of fiberglass fabric impregnated with graphite on both sides to increase the temperature resistance capability of the finished product. The coating also improve the performance where flexing is involved. Graphite coated glass cloth is high temperature & corrosion resistant. It also has excellent heat resistance, good abrasion and release properties.

Features: High Temperature And Heat Resistance, Good Abrasion

Application: welding defender, welding blanket ,fire blanket, fire curtain, high temperature, foundry splash protection, heat protection quilts, heat shields, sleeves, connectors and insulation jackets

PRICE: USD7 per square meter

UNIT: square meter

MOQ: 500square meters

Weight: 200gsm-3000gsm or customized

Width: 1m-2m or customized

Yarn Type: E-glass

Standing temperature: 700℃

Product name: Graphite coated fiberglass fabric

Coating/Finish/Surface Treatment: Graphite coated

Roll length: 50 meter or customized

Color: Black

Weave Type: plain woven

Alkali content: Alkali free

Processing service: cutting

Material: fiberglass fabric, Graphite

Thickness: 0.2mm to 3mm

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Graphite coated glass cloth rolls packed in cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q:Can fiberglass fabric be used for making curtains or blinds?

- Fiberglass fabric is an excellent choice for creating curtains or blinds due to its versatility and numerous advantages. Firstly, its high durability and resistance to wear and tear make it perfect for long-lasting window coverings. Additionally, it is flame-resistant, ensuring safety in your home. Its lightweight nature also facilitates easy installation and operation. Furthermore, fiberglass fabric comes in a variety of colors and designs, allowing for flexibility in terms of aesthetics and matching room décor. Lastly, it offers exceptional light control and privacy, making it an ideal option for curtains or blinds. In conclusion, fiberglass fabric is a practical and functional choice for crafting curtains or blinds.

- Q:How is fiberglass fabric used in the production of insulation sleeves?

- Fiberglass fabric is used in the production of insulation sleeves due to its excellent thermal properties and durability. Insulation sleeves are designed to provide thermal insulation and protection for various applications, such as industrial pipes, wires, and cables. When manufacturing insulation sleeves, fiberglass fabric is typically used as the outer layer due to its high resistance to heat and fire. The fabric acts as a barrier, preventing heat transfer and minimizing the risk of fire hazards. This is particularly important in industrial settings where high temperatures are present, as it helps to maintain a safe working environment. Additionally, fiberglass fabric is known for its insulation capabilities. It has a low thermal conductivity, meaning it is a poor conductor of heat. This property allows the fabric to effectively trap heat within the insulation sleeve, preventing energy loss and reducing the need for excessive heating or cooling. Furthermore, fiberglass fabric is highly durable and can withstand harsh environmental conditions, chemicals, and UV radiation. This makes it suitable for insulation sleeves that are exposed to outdoor elements or corrosive substances. The fabric also has good tensile strength, allowing it to withstand mechanical stress and maintain its shape over time. In summary, the use of fiberglass fabric in the production of insulation sleeves is essential for providing thermal insulation, fire protection, and durability. Its excellent thermal properties, resistance to heat and fire, and ability to withstand harsh conditions make it an ideal material for insulating various applications in industries such as construction, automotive, and manufacturing.

- Q:What are the differences in the quality and performance of domestic glass fiber cloth and imported fiberglass fabric?

- Glass fiber is made up of glass fiber yarn, stacked into a network structure to intercept and absorb impurities, can break the oil in the water as a knife, collect water, improve the quality of oil, and extend the life of equipment.

- Q:What's the function of fiberglass cloth? Where can I use it?

- Glass fiber cloth weight is relatively light, used in the new type of glass fiber insulation composite wind pipe, can be very good to reduce the color steel, glass fiber, air duct weight, conducive to workers to manufacture and install

- Q:Does fiberglass fabric provide UV protection?

- Yes, fiberglass fabric does provide UV protection. Fiberglass itself has inherent UV-resistant properties, making it an excellent choice for applications that require protection from harmful ultraviolet rays. The fabric made from fiberglass fibers can effectively block a significant amount of UV radiation, offering a high level of protection against the sun's harmful rays. This makes it a popular choice for outdoor products such as awnings, sunshades, and outdoor furniture covers, where UV protection is essential. Additionally, fiberglass fabric is also known for its durability and resistance to fading, further enhancing its ability to provide long-lasting UV protection.

- Q:Are fiberglass fabrics suitable for use in the automotive industry?

- Yes, fiberglass fabrics are suitable for use in the automotive industry. They are lightweight, strong, and durable, making them ideal for various applications such as reinforcing body panels, manufacturing interior trim components, and creating structural supports. Fiberglass fabrics also offer resistance to heat, chemicals, and corrosion, making them a reliable choice for automotive applications.

- Q:How is fiberglass fabric used in the marine industry?

- Fiberglass fabric is commonly used in the marine industry for its strength, durability, and resistance to corrosion. It is used in the construction of boats, yachts, and other watercraft to reinforce the hull, decks, and cabin structures. The fabric is often combined with resin to create a composite material that provides excellent structural integrity, making the vessels more lightweight and fuel-efficient. Additionally, fiberglass fabric is used to manufacture components like hatches, panels, and insulation, as it offers good thermal and sound insulation properties.

- Q:How is fiberglass fabric sewn?

- Fiberglass fabric is typically sewn using a heavy-duty sewing machine equipped with a strong needle and thread. The process involves aligning the edges of the fabric panels and feeding them through the machine, allowing the needle to pierce through the fabric layers and create stitches. It is important to use a sharp needle specifically designed for sewing fiberglass fabric, as this material can be tough and abrasive, potentially causing regular needles to break or become dull quickly. Additionally, using a sturdy thread, such as a polyester or nylon thread, is crucial to ensure the durability and longevity of the seams. Sewing fiberglass fabric requires skill and precision, as the material can be slippery and difficult to handle. It is recommended to practice on scrap pieces before attempting to sew large or complex projects.

- Q:Is high strength fiberglass cloth the same as high silica fiberglass cloth?

- For example, high silica glass fiber cloth commonly used wellav glass. Therefore, high silica glass fiber cloth contained in the high strength glass fiber cloth, belonging to the concept of containing.

- Q:How is fiberglass fabric different from other types of fabric?

- Fiberglass fabric is different from other types of fabric primarily because it is made from woven glass fibers rather than natural or synthetic fibers. This gives it unique properties such as high strength, heat resistance, and insulating capabilities, making it suitable for various industrial applications. Additionally, fiberglass fabric is non-flammable, corrosion-resistant, and has low water absorption, setting it apart from traditional fabrics like cotton, polyester, or nylon.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Temperature Graphite Coated Fiberglass Fabric Heat Resistant Glass Cloth

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords