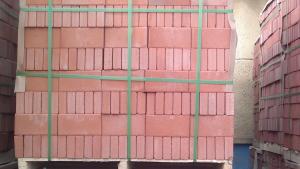

High strength, low thermal conductivity High Alumina insulation firebrick for Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Block | Material: | Alumina Block |

| SiO2 Content (%): | customized | Al2O3 Content (%): | customized | MgO Content (%): | customized |

| CaO Content (%): | customized | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | customized |

| SiC Content (%): | customized | Model Number: | STA-000123 | Brand Name: | CNBM |

| AL2O3%: | 48 | Fe2O3%: | 2.0 | Densityg/ cm³ ≤: | 1.0/0.9/0.8/0.7/0.6/0.5 |

| Compressive strengthMpa≥: | 4.0/3.5/3.0/2.5/2.0/1.5 | linear change on reheating: | 1400C/1400C/1400C/1350C/1350C/1250C | thermal conductivity350°C±25 °C W/m.k: | 0.50/0.35/0.35/0.30/0.25/0.20 |

Packaging & Delivery

| Packaging Details: | Polythene-foamed sheet bag and wooden case and wooden pallet or pack as customer's requirements. |

| Delivery Detail: | about 30 days |

High strength, low thermal conductivity High Alumina insulation firebrick

This product uses high-grade hollow ball and alumina as the main raw materials, made by high temperature sintering. With features of High strength, low thermal conductivity, suitable for 1400°C below’s furnace insulation and lining.

Chemical properties

Lg-1.0 | Lg-0.9 | Lg-0.8 | Lg0.7 | Lg0.6 | LG0.5 | |

AL2O3% | 48 | |||||

Fe2O3% | 2.0 | |||||

Densityg/ cm³ ≤ | 1.0 | 0.9 | 0.8 | 0.7 | 0.6 | 0.5 |

Compressive strengthMpa≥

| 4.0 | 3.5 | 3.0 | 2.5 | 2.0 | 1.5 |

linear change on reheating≤2%×2h Lab Temperature °C | 1400 | 1400 | 1400 | 1350 | 1350 | 1250 |

thermal conductivity350°C±25 °C W/m.k | 0.50 | 0.35 | 0.35 | 0.30 | 0.25 | 0.20 |

- Q:What is the content of free silica in the refractory bricks of high alumina bricks?

- In the meantime, the free silica content of silicon brick is as high as 90% above. Therefore, the most serious damage is silicon brick, followed by clay brick, high alumina brick, magnesia brick and so on.

- Q:What is the high temperature limit of refractory bricks and refractory soil?

- Fire clay -- usually refers to folk point stove furnace set with a kind of soil, limit under atmospheric pressure of 1500 degrees fire clay soil 1, properties and uses: clay brick of weak acid refractory material, its thermal stability is good, suitable for hot blast furnace, boiler and flue, smoke chamber lining, etc..2, product specifications form: standard shape, general, special-shaped and special-shaped brick. Physical and chemical properties of fireclay bricks.

- Q:What is the density of a super high alumina brick and what is the price?

- Super high alumina brick, alumina content of 80% bricks, bulk density of 2.7g/cm3 or more, the factory price of about 1900 yuan

- Q:The difference between ordinary and diatomite brick refractory brick

- Refractory brick belongs to a large class, according to different materials used are divided into: high alumina brick, dolomite brick, magnesia chrome brick, magnesia spinel brick, phosphate brick, carborundum brick, brick, mullite bricks etc..

- Q:What are the lining structures of lime rotary kilns and what are the requirements for refractories?

- The rotary kiln lining structure of rotary kiln and requirements on refractories calcining active lime according to the general output is divided into Nissan 300t, 400 t, 600 t, 800 t, 1000 t, 12000 t of kiln type, calcining zone temperature at 1350 degrees celsius. The kiln is divided into a discharge end, a cooling zone, a burning zone, a preheating zone and a feeding end, and the temperature of each section of the kiln ranges from 1000 DEG C to 1350 DEG C, and the requirements for refractory materials are different. The kiln refractory materials not only to withstand the high temperature impact, but also need to bear the material erosion, kiln rotation stress produced, so not only on the physico-chemical properties of refractory materials have strict requirements, but also for the construction of brick should be strictly.

- Q:How to make refractory bricks and boiler wall adhesion more firm?

- If the condition, the user heat-resistant steel welding grip nails, expansion joints can not be too big.. Also to use high temperature aluminum brick, high temperature resistance, but also to extend its use cycle.

- Q:The difference between aluminium refractory and magnesia refractory

- Aluminum refractory belongs to neutral refractory material, usually refers to silicon aluminum refractory materials, such as: high alumina brick, clay brick, high alumina castable and other products, the production of raw materials is mainly bauxite.

- Q:What is the price of the first grade high alumina brick?

- Many factories in Xinmi have high alumina bricks, but they must choose a regular factory. Kuwait refractory level high aluminum brick price at around 1600, the quality of double stable supply

- Q:Introduction of high alumina brick

- Made from alumina or other raw materials of high alumina content; formed and calcined. High thermal stability, fire resistance above 1770. Slag resistance is good, used for masonry steel smelting furnace, glass furnace, cement rotary furnace lining.

- Q:What are the main components of high alumina bricks?

- Sweat is like water mineral alumina bauxite, aluminum ore, magnesite, waves of gibbsite. Anhydrous alumina raw material, such as corundum, alumina, fused corundum. High alumina brick Zhengzhou gold company specializing in the production of various specifications, you can directly ask their technical staff.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High strength, low thermal conductivity High Alumina insulation firebrick for Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords