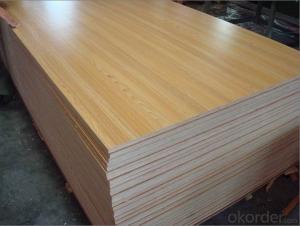

High Quality Laminated Veneer Lumber

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The details of the High Quality Laminated Veneer Lumber

|

Standard size |

38/*225*3900 |

|

Core |

pine |

|

Glue |

WBP |

|

Density |

600KG/m³ |

|

Packing details |

57 sheets/pallet,27pallets/40HQ |

Specifications of the High Quality Laminated Veneer Lumber

A) Max Length: 8000mm

B) Thickness: 10-120mm

C) Width: as request

D)Glue: WBP/MR

E) Core: popular/pine/eucalyptus

Features of the High Quality Laminated Veneer Lumber

1) High bending strength

2) Little liner expansion con efficient

3)Strong nail holding

4)Moisture proof and easy work

5)Tight Construction and high Strength

6)No ratten or decay

7)Low formaldehyde emission

The following pictures for your reference.

- Q:How do you print or pattern on wood products?

- 2, gelatin film on the original version of the paper on the rules line, multi-color version of the rules are used as installed version of the rules. Put the engraved version together with the original, placed in the appropriate position of the screen plate, according to the rules of the original rules of the rules of the binding rules with milky white paste attached to the screen plate, and paste with a paper sheet. There are several sets of color with a few screen plate set a unified rules. The original with the engraved version, placed in the rules of the board, put down the screen box, in the top of the screen with an iron aligned engraved Gelatin version of the four corners of the edge of the ironing, so that gelatin version of sticky on the screen after the original release. Put some thick paper on the plate, put down the screen frame so that the gelatin carved paper pad flat, and then covered with a polyester film on the film from the role of the interval, with iron back and forth several times, so that gelatin film Hot on the screen. After a good version of the natural dry, and then peel off the liner and the use of ketone to the opposite side of the liner and the interval between the coated PVC overshoot scrub clean. If the version of the place can be used to retreat glacial acetic acid, if the knife edge of the knife marks and small strokes off, you can use the pen dipped in plastic repair. 3, nitro varnish modified film on paper version of nitro-varnish modified film on the version of the same method. (5) closed network The screen is about the screen outside the screen with colloidal sticky block up, so that the printing plate in the printing does not leak ink. Wax grams of film version of the network can be used nitro-varnish, gelatin solution can be sealed gelatin film version and nitro-varnish modified film version. The printed plate is printed and dried. Second, the photosensitive screen printing plate

- Q:How can the wood products of white paint long time does not change color?

- On this point, you can enter in Baidu "decorative pollution" and "EU decorative paint guidelines 2007-2010" can be found. Wall paint, are generally water-soluble, safe and environmentally friendly are no problem, the general brand in the high-end product line are good. Such as to Granville, Green Bo, Dulux, China Resources, Dabao, Carpoly and so on. As for the state, is the Japanese goods, I resist. Added: the current is not yellowing only water-based paint.

- Q:Building decoration commonly used in wood decorative products which

- 1, wood classification Wood according to different classification criteria can be divided into different types, there are two general classification methods, one by tree species; the second is by the degree of processing points. According to tree species: divided into coniferous trees and broadleaf trees Wood Category 1: by tree species points conifer Leaves slender as needle, mostly long green trees pine, pine, shirt wood, ginkgo and so on. Trunk material is straight and tall, easy to get great material; material uniform and soft, easy processing, is a soft wood; material strength, surface density and expansion and contraction of small, strong corrosion resistance. It is suitable for the load-bearing structure of the hidden part of home improvement. Broadleaf trees Leaves large, veins reticulate, deciduous. Ash, camphor, walnut, cherry, teak, red sandalwood, poplar, boxwood, red beech, white beech and so on. Trunk straight part of the shorter, hard material, processing more difficult, is a hard wood; hardwood swelling and warping deformation, easy to crack; texture natural beauty. It is suitable for making the main finishes of home improvement decoration and furniture manufacturing. According to the degree of processing points: divided into the original article, logs and board three kinds of materials Wood classification 2: according to the degree of processing points The original: the trees are cut, the pruning, remove the skin, roots, trees, but no processing of wood

- Q:Water content is too high or too low, will cause the quality of wood in the home improvement

- multi-application of man-made sheet. Compared with the solid wood materials, a variety of man-made sheet of textured performance to be much more stable

- Q:South wet and humid, cabinets, beds and other wood products are shelter are long mold, and how to prevent moldy it?

- I myself is Cantonese, so I also know that the cupboard moldy trouble, especially when the weather back to the South, my computer desk drawer and the like are covered with mold. That my experience is to go to the supermarket to buy a few moisture-proof pills, place in the moldy place.

- Q:What are the wood products? Is the wooden product environmentally friendly?

- Wood products are made of wood raw materials, processed, the formation of the product. Wood products are divided into the following categories: furniture, wood products, office wood products, wood products, gardening wood products, wood products, and now high-tech wood products. Wood carving is only a branch of woodwork.

- Q:Some workers in order to cut corners, in the white latex watered.

- When you purchase the decoration of the wood, only eye view, hand touch is determined to determine the moisture content of wood.

- Q:How to process woodwork

- Ordinary carpentry lathes can be processed, CNC woodworking lathes can do. Ordinary carpentry can not be processed, CNC woodworking lathe can not do. CNC lathe is only an additional part of the automation, improve the manufacturing accuracy, reduce labor intensity, improve production efficiency. The basic functions are the same: processing a variety of roundabout.

- Q:Who knows the art of wood on the brush is what oil?

- 2, on the role of varnish analysis: Varnish is pigment-free transparent or with a light yellow paint, good gloss, film fast, wide use. The main ingredients are resins and solvents or resins, oils and solvents. [Apply to the surface of the object, the formation of a protective, decorative and special properties of the coating, dry after the formation of smooth film, showing the original pattern of the surface. To Varnish as home decoration in the scene of the construction of the most important lacquer is a unique reason. Polyester paint for the construction environment and construction process requirements are high, and varnish is not. In the process of brushing the flow often occurs in the sagging (tears), for example, polyester paint in the process of forming the sagging process is difficult to re-dissolve solidification, and varnish smoothness is good, there is sagging also It does not matter, then brush it again, sagging can be re-dissolved.

- Q:How to handle the business license and tax registration certificate for wood products processing plant?

- he first to go to the local Trade and Industry Bureau to apply for the name of the pre-nuclear, that is, they want a business name, to the Trade and Industry Bureau inquiries are available, if not available have to change one, if available, find an accounting firm issued a capital verification report (private Limited shareholders more than two people, the registered capital of 30,000 yuan can be).

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong,China |

| Year Established | 1987 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | Europe;North America;Asia |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Lianyungang;Qingdao |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 2000 |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

High Quality Laminated Veneer Lumber

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords