High Quality ISO Standard Food Industry PVC/PU Conveyor Belt Flat Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

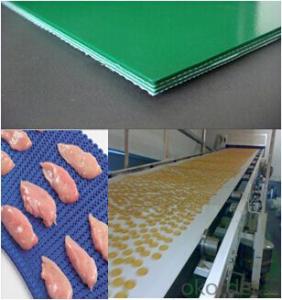

High Quality ISO Standard Food Industry PVC/PU Conveyor Belt Flat Conveyor Belt

PVC/PU Conveyor Belt:

Anti-static and tearing resistant

Abrasion and oil/heat/fire resistant

Application:

PVC Conveyor belt has a wide range of products which can be applied in different industries, such as: tobacco, food, logistics, post, airport machinery, phamaceuticals, chemistry, electronics, printing, cable pulling, steel wrapping and sports entertainment.

Product Feature

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise

| Top cover | Bottom Cover | Characte ristics | Temp.℃ | FABRIC Plies | Max. Width | |||

| Colour | Surface | Colour | Surface | Min | Max | |||

| White | Smooth | Natural | Impregnated | Antistatic | -15 | 90 | 1 | 2000 |

| White | Matt | Natural | Impregnated | Antistatic | -15 | 90 | 2 | 2000 |

Dark Green | Matt | Natural | Impregnated | Antistatic | -15 | 90 | 2 | 2000 |

| White | Smooth | Natural | Fabric | Antistatic | -15 | 90 | 2 | 2000 |

| White | Smooth | Natural | Fabric | Knife Edge Application | -15 | 90 | 2 | 2000 |

Product Image

Pls contact me freely if any inquiry or questions,thank you!

- Q:When rubber products are hardened, what methods soften?

- Either hardening or vulcanization. Vulcanized rubber becomes elastic rubber. This is an irreversible process. The elastomer can be changed into a plastic regenerated rubber by the desulfurization process.

- Q:What kind of rubber does TPE belong to?

- TPE does not belong to rubber.Although TPE has a tensile resilience similar to that of ordinary rubber, TPE is thermoplastic and rubber is thermosetting. Rubber needs cross-linking. It can not be reprocessed after molding. TPE can be processed repeatedly.

- Q:Natural rubber, general rubber, synthetic rubber. Are these all rubber products?

- Not rubber products, rubber classification, rubber is divided into natural and synthetic rubber, synthetic rubber and general rubber and special rubber! The so-called rubber products refers to the use of rubber as raw materials to produce products, such as tires, belts, conveyor belts and so on.

- Q:Can PVC blend with rubber?

- Ding Qing rubber is highly polar and can mix with any proportion of PVC. Other polar rubbers, such as chlorinated polyethylene and chlorinated polyethylene, can be mixed.

- Q:What is the temperature of ordinary silicone rubber resistant to low temperature?

- Heat resistance of silicone rubber in the air is much better than that of organic rubber, at 150 DEG C, the physical and mechanical properties basically unchanged, semi permanent use, under the temperature of 200 DEG C can be used continuously for more than 10000h; 380 DEG C can be used for some time. Silicone rubber is therefore widely used as rubber parts in high temperature applications.

- Q:Aging of rubber parts for automobiles

- Automobile rubber parts aging factors are: oxygen, ozone, heat, light, mechanical stress, moisture, oil, other chemicals or radiation, etc.. Attention should be paid to water and oil here:The alternate action of high temperature and oxygen 1. long-term water and in the external environment under the accelerated aging of rubber;2., the oil will penetrate the rubber, so that swelling occurs, rubber performance will be reduced. Therefore, trucks should avoid shock absorption of rubber bushings, oil and diesel in various occasions, including maintenance.

- Q:How to distinguish between good and bad silicone rubber gasket?

- Silicone products high tear strength anti destruction ability outstanding, long service life, less susceptible to outside interference, the tear strength of silicone products poor general performance gap is easy to appear in the tearing process, so as to force rapid expansion and cracking damage phenomenon.

- Q:How do ordinary NBR and EPDM materials differ?

- Three EPDM (EPDM) is a non conjugated diene copolymer of ethylene and propylene and a small amount of an ethylene propylene rubber, represented by EPDM, because of its main chain is composed of saturated hydrocarbon chemical stability, only in the side chain containing unsaturated double bond, so the ozone resistance, heat resistance, weather resistance etc. aging resistance, can be widely used in automobile parts, building waterproof materials, wire and cable sheath, heat-resistant hose, rubber belt, automotive seals etc..

- Q:What plastic rubber will not be subjected to oil (such as transformer oil) by quality (e.g., aging, dissolution)?

- Generally, aging and dissolution occur. If you want to make the structure, you can choose XF POM C13031 Ticona of the company. This is the company specializing in the development of temperature resistance, oil (especially gasoline, diesel) products.

- Q:Doors and windows shock absorber seals, rubber blocks, rubber products, do not know where to buy, where suppliers?

- The product has good elasticity and anti compression deformation, and has excellent aging resistance. It adopts the microwave vulcanization process to form at one time. The surface is smooth and beautiful, without any trace.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality ISO Standard Food Industry PVC/PU Conveyor Belt Flat Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords