Heat Insulation Refractory Aerogel Thermal Insulation Felt

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Description

Aerogel Insulation Felts

Using special nanotechnology, It combines a silica aerogel with reinforcing fibers to deliver very low thermal conductivity, low density and good flexibility in an environmentally safe product. It provides excellent properties of waterproof, sound absorption and shock absorption. It is an alternative to the common, environment unfriendly, inferior insulation products, such as PU, asbestos insulation felt, silicate fibers, etc.

2.Specifications

1.Superior Thermal Performance

2.Long service life

3.Environmentally Safe

4.Sound resistance

3. Advantages

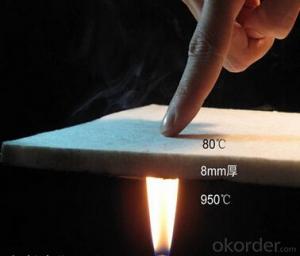

(1).Superior Thermal Performance

The maximum use temperature is 1000℃,Its thermal conductivity is 1/3~1/5 of common insulators, helping reduce heat loss and optimizing space utility.

(2). Long service life

Unlike other traditional insulation materials, aerogel ’s three- dimensional, structure inhibits sintering warpage, and particles stack which may occur under hot temperature for long time. Therefore, aerogel insulation has long service life.

(3). Physically Robust:

It has flexibility and high tensile strength, resisting stretching and stress from linear contraction when temperature changes.

(4). Environmentally Safe:

Composed of inorganic materials, it contains no hazard. Stripping little chloridionm will cause no corrosion to the equipments and pipes.

Low and ultra-low temperature equipment and piping applications

Petrochemical, power equipment applications

(5). Easy to Install

Extremely low density (200kg/m3) contributes to easy-to-cut and easy-to-install.

4. Technical Standard

Property | Unit | Techicial Standard | |

(refractoriness) | ---- | A Grade | |

(Density) | kg/m3 | <220< span=""> | |

(Lyophobic) | % | >99 | |

Thermal Conductivity | 25℃ | W/(m·K) | ≤0.023 |

70℃ | ≤0.029 | ||

200℃ | ≤0.036 | ||

300℃ | ≤0.045 | ||

400℃ | ≤0.056 | ||

5. Application

Oil pipe, steam pipe, refrigerator interlining, oil tank, central airconditioning pipe, chemical pipe with the requirement of fire resistance, vehicle thermal insulation, national defence, military industry, heat supply pipelines in city insulation, biological medicine pipes and equipment and so on.

- Q:Which thermal insulation materials are the best for air-conditioners? Is it rubber and plastic, PEF or glass wool?

- Rubber and plastic is a better choice for conduits.

- Q:What are the differences among glass wool, rock wool and mineral wool?

- Glass wool: The main raw material is glass, the fire rating of which is A-level, and the heat conductivity coefficient is 0.037, the shrinkage temperature is around 270 degrees. Uses: It has a significant cold insulation performance. Rock wool: The main raw material is basalt, the fire rating of which is A-level, and the heat conductivity coefficient is 0.040, the shrinkage temperature is around 730 degrees. Uses: It can be used in high-end engineering projects such as construction, shipbuilding, petrochemical ones. Mineral wool: The main raw material is slag, the fire rating of which is A-level, and the heat conductivity coefficient is 0.044, the shrinkage temperature is around 680 degrees. Uses: It can be used as filling and thermal insulation materials for curtain walls.

- Q:Can glass wool be used for external wall insulation?

- Yes, glass wool belongs to the category of glass fiber, which is a kind of man-made inorganic fiber. With good thermal insulation and sound-absorbing properties. Currently the relatively good glas wool on the market is Huamei Senda.

- Q:What is the density of glass wool?

- Usually, wool thickness is15MM 25MM 30MM 40MM or 50MM .. Unit weight is 12K 16K 24K 32 or 48K. Glass wool with high unit weight should be reserved. And the price depends on the purposes.

- Q:What properties does glass wool felt have?

- It is a felty material which is produced by applying adhesive on glass wool and then being cured by heating. Glass wool felt has a lighter volume-weight than board with good resilience and cost performancefelt. It can be cut freely based on needs, which makes it easy for construction. Glass wool felt is a formed coiled material aiming to meet the needs of large-scale paving work. It palys a role of thermal insulation, reducing noise pollution and improving common environment. Common glass wool is mainly used as thermal insualtion for interior architecture, refrigeration equipment and vehicles as well as shock absorption, sound insulation, noise control and more for household appliances. Those glass wool felts added special materials like glass wool felt with aluminium foil venner have the functions of thermal insulation and anti-radiation, which will mainly used in high-temperature workshops, machine rooms, equipment control rooms, etc.

- Q:What kind of glass wool pipe is this? Where is it sold?

- I do not know the specification of it.

- Q:Does anyone know about the general unit weight of glass cotton color steel?plate?

- Glass cotton is the general term of fibrous silicate minerals which can be split into long and narrow flexible fibers. Glass cotton are manufactured to meet the requirement of large-area pave, apart from the unique thermal insulation property, they are good at fireproofing, shock and sound absorption which help to reduce noise pollution, and improve working environment. The thickness of rock wool board : 40 to100 mm. The unit weight is 80 to 150kg / m?. Glass wool can be processe into different products. The thickness: 25 to 100mm. The unit weight is 30 to 80kg.

- Q:What are the differences between glass wool felts and rock wool board in terms of appearance, and how to distinguish them?

- The most significant difference is color. Glass wool is white, while rock wool is yellow.

- Q:Is centrifugal glass wool board suitable for home use?

- It can be easily broken and produce fine suspended particles. If the glass wool is of poor quality, you'd better use plastic bags or non-woven fabric to wrap it when using. So you must choose brand whose products are of good quality. Also if it is for the acoustics, it will do harm to the human body if inhaled into the lungs. So be sure to choose a renowable brand o centrifugal glass wool.

- Q:Which is more expensive between glass wool and rock wool?

- Which Gree factory do you work for? I work for the third factory.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heat Insulation Refractory Aerogel Thermal Insulation Felt

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords