Halogen Free FT2 Flame Retardant Thermoplastic Elastomer Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

plastic granules:

FT2 flame retardant Halogen-free TPE cable compound

plastic granules: 1, Type and application: USB wires, telecommunication cables, charger wires and HDMI wires

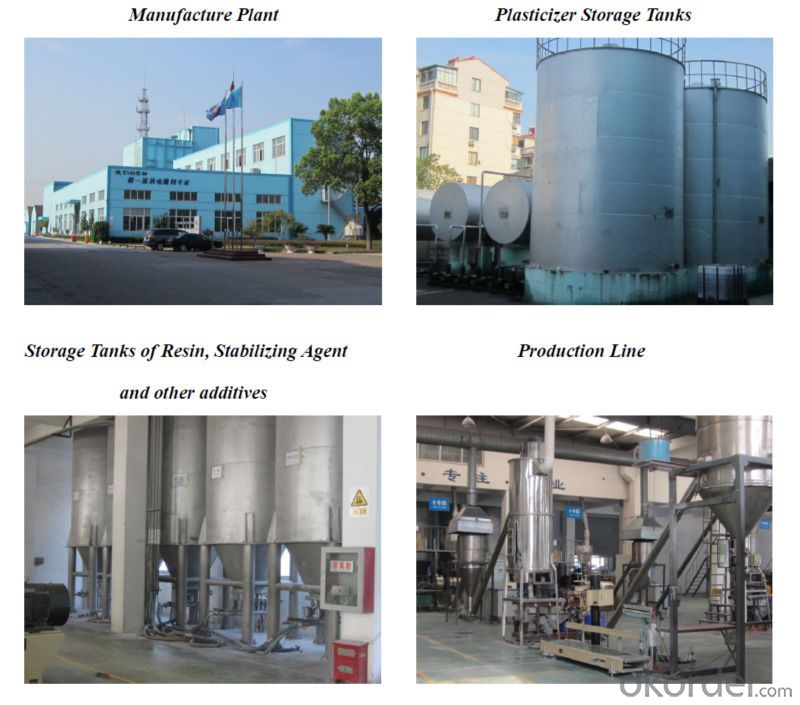

2, Introduction Environmental friendly halogen-free TPE cable compound, based on styrene elastomer, is made into granular by mixing, plasticization and granulation with special modifier, and other special additives. It has goodresilience, scratch-resistant and flexibility. The products meet various special requirements, such as different hardness, UV stable, fog surface and etc. This material, with exquisite and smooth appearance, has excellent performance of anti yellowing, weather resistant temperature resistance, without halogens, heavy metals, meeting the RoHS, REACH, and other environmental standards. 3, Processing: The compound can be processed with conventional extruders, and the screw with a minimum 25:1 L/D and a compression ratio of 2.5 is recommended. The following temperature(°C) profile of extruder is recommended: Note:Compound should be dried at 80-90°C before use, which has been stored more than two months. 4, Storage and transport Packaging:20kg/bag,PE film inside bag, and PP composite outside bag. Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be clean, cool, dry, and ventilated. 5, Properties: 6,Company Pictures

|

- Q:What two ingredients fit together to solidify like plastic?

- Secondly, whether or not the material can be calibrated in accordance with the displacement sensor (or embedded in it), and then the gap distance is measured by reading after installation.

- Q:PP plastic stool surface with those raw materials, what is the ratio?

- PP has good stress cracking resistance and has a high bending fatigue life, commonly known as "fold gum"".The comprehensive performance of PP is better than that of PE.

- Q:Characteristics and uses of CA plastics

- Commercially available products can be divided into general cellulose acetate (acetyl - 37% - 40%). Plasticizers are often added as injection molded parts, such as toothbrushes, brushes, etc.. Cellulose acetate with a high acetyl content (40% to 42% acetyl), white, granular, powdery or cotton solid. The light stability, not easy to burn, in dilute acid, gasoline, mineral oil and vegetable oil in stability, swelling in chloroform, insoluble in acetone, methyl acetate, can dilute alkali erosion, has advantages of toughness, transparency, good gloss, good melt fluidity, easy molding. Dichloromethane homogeneous method using refined cotton linter and acetic acid with acetyl sulfate as catalyst, esterification, hydrolysis in the presence of dichloromethane solvent, can be combined with cellulose acetate acetic acid content in 60% + 0.5% range. The traditional method is to use dry cotton, acetic acid in the presence of catalyst activation, sulfuric acid, acetic acid and acetic anhydride with mixture of acetylation, then adding dilute acetic acid hydrolysis to belong to the degree of substitution, and catalyst, precipitation, acid washing, rice drying. After partial hydrolysis, cellulose acetate is called two, and the degree of esterification is 220~270. Without hydrolysis, that is, the degree of esterification, the gamma value of 300, said three cellulose acetate. Two cellulose acetate plastic handle, can do all kinds of tools of computer and typewriter alphanumeric keys, phone chassis, car steering wheel, textile equipment parts, radio switch and insulation, pen, spectacle frame and lens, toys, daily necessities, but also do desalination membranes. Three cellulose acetate, high melting point, can only match into solution processing, used as a movie film, X film, light film, electromagnetic diaphragm insulating tape, transparent container, the silver zinc battery.

- Q:What does plastic material include?

- Method for identifying toxic plastic bags. Water detection method: put a plastic bag into the water, non-toxic can be surfaced, and poisonous won't rise; hand touch detection method: white or colorless transparent is non-toxic, the hand has a sense of lubrication, the surface like wax; color: color detection method of toxic haze or yellow, red and black. Feel sticky; jitter method: take a plastic bag shaking, the sound crisp sound stuffy astringent toxic and non-toxic.

- Q:Aluminum Alloy door corner with what plastic raw materials do?

- If the diagonal code requirements are not high, you can arbitrarily first a PP material.

- Q:What are the POE plastic raw materials?

- POE classification of plastics raw materials:Plasticizing properties: Thermoplastics and thermosetting plastics.Divided by use: General Plastics and engineering plastics.

- Q:What are the plastic raw materials for this purpose?

- From the bathroom supplies we use when we wake up, the tableware we use for breakfast, the stationery we use for work and study, the seat cushion for sleeping, the mattress, and the shell of TV set, washing machine and computer

- Q:What are the APP of plastic raw materials?

- Thermoplastic engineering plastics (polyamides, polycarbonates, POM, PET, PBT and others)

- Q:What plastic material is resistant to high temperature?

- PPS is a kind of special engineering plastics with excellent comprehensive performance. Dimensional stability of PPS has excellent temperature resistance, corrosion resistance, radiation resistance, flame retardant, balanced and excellent physical and mechanical properties and excellent electrical properties and other characteristics, are widely used as structural polymer materials, by filling after modification, widely used in special engineering plastics. At the same time, it can be made into various functional films, coatings and composite materials. It has been successfully applied in the fields of electronics, electrical appliances, aeronautics and Astronautics, automobile transportation and so on. Domestic enterprises have actively developed and formed a certain production capacity, which changed the situation of relying solely on imports in the past. However, there are still some problems in China's PPS technology, such as low variety of products, high functional products, and urgent expansion of production capacity, which will be the focus of the next development of PPS.

- Q:What type of raw material for plastic straw?

- The basic properties of plastics depend mainly on the nature of the resin, but additives also play an important role. Some plastics are made up of synthetic resins, with or without additives such as plexiglass and polystyrene. The so-called plastic, in fact, it is a kind of synthetic resin, the shape of the natural resin with pine resin similar to, through chemical means of artificial synthesis, and is called plastic.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Halogen Free FT2 Flame Retardant Thermoplastic Elastomer Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords