Greenhouse Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction to CNBM:

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

Features of Greenhouse Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray:

· Material: HIPS

· Thickness: 0.5mm-1.5mm, Standard:1mm

· Weight: 80g(±5)g-230g(±5)g, Standard weight:155g(±5)g

· Size: length:490mm-540mm, width:190mm-345mm,depth:25mm-150mm

· Standard:540mmX280mm

· Cell count: 18-512

· Package: In Carton

· Warrenty: 8-10 times

Picture of Greenhouse Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray:

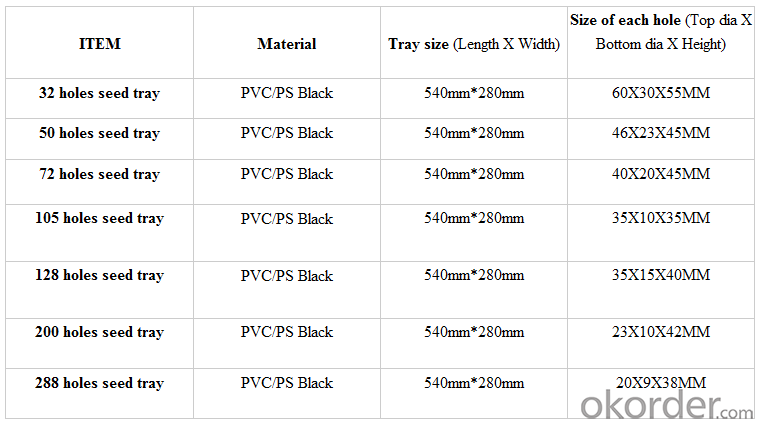

Specification of Greenhouse Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray:

FAQ of Greenhouse Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray:

Q:1.How many times can the seed tray be used?

A: Under the same environment, it is decided by the thickness. Usually 0.6mm thickness can be used for 1 or 2 times.

1.0 thickness can be used for 3-4 times. 1.5 thickness can be used for 8-10 times.

Q: 2.How long is the production time?

A: Usually one to two weeks.

Q: 3.How is the seed tray being packaged?

A: They can be packaged in carton or pallets. Carton size is 1375px*725px*1250px.

- Q:How do you prevent ground cover from spreading into unwanted areas?

- One effective way to prevent ground cover from spreading into unwanted areas is by installing physical barriers such as plastic or metal edging or landscape fabric. These barriers can be buried slightly into the soil to create a boundary that restricts the growth and spreading of the ground cover. Regular maintenance, such as trimming or pruning, should also be carried out to prevent any overgrowth and to keep the ground cover within its designated area.

- Q:cardboard or plastic tampons?? which work better??

- plastic is easier to insert and more comfortable

- Q:How do I choose ground cover for a coastal area with strong winds?

- When choosing ground cover for a coastal area with strong winds, it is important to consider plants that are resilient and can withstand harsh conditions. Opt for low-growing, compact plants that have strong root systems to anchor themselves in the soil. Look for salt-tolerant varieties that can withstand the high salt content in coastal environments. Some suitable options include ornamental grasses, creeping junipers, and coastal wildflowers. Additionally, consult with local gardening experts or nurseries for specific recommendations tailored to your coastal area's unique conditions.

- Q:How do you remove unwanted ground cover plants?

- To remove unwanted ground cover plants, you can manually pull them out by hand, ensuring to remove the roots as well. Alternatively, you can use a garden fork or shovel to loosen the soil around the plants, making it easier to lift them out. Additionally, applying a herbicide specifically designed to target ground cover plants can be an effective option, but it's important to read and follow the product instructions carefully to ensure safe and proper use.

- Q:When I bought a cage it had some toys 2 plastic perches and a swing I threw everything out but the swing and perches and I disinfected them I was wondering are the perches ok for my bird?

- Plastic perches are no good . they are to smooth, you need to get some wood ones or even tree branches , if possible from Apple .or Willow trees. Plastic perches do not allow the birds to grip correctly and can harm the feet , wood perches and branches are more natural, for your birds to get their claws around. Breeder

- Q:Can ground cover be used to create a natural-looking border around a pond or water feature?

- Yes, ground cover can definitely be used to create a natural-looking border around a pond or water feature. Ground cover plants, such as creeping thyme, sedum, or pachysandra, can help soften the edges of the pond or water feature, provide a seamless transition between the water and surrounding landscape, and create a visually appealing and cohesive natural border. These low-growing plants also help to prevent soil erosion and filter water runoff, contributing to the overall health and sustainability of the pond or water feature ecosystem.

- Q:How do you prevent ground cover from spreading too aggressively?

- There are a few strategies to prevent ground cover from spreading too aggressively. First, regular maintenance such as trimming and pruning can help keep it in check. Additionally, creating physical barriers like edging or installing root barriers can prevent the spread of ground cover. Lastly, selective removal of unwanted shoots or runners can help control its growth and prevent it from overtaking other areas.

- Q:How do plastic greenhouse covers benefit crop production?

- Plastic greenhouse covers benefit crop production by creating a controlled environment that promotes optimal growing conditions. These covers help regulate temperature, humidity, and sunlight exposure, creating a favorable microclimate for plants. They also protect crops from extreme weather events, pests, and diseases, thereby increasing yields, extending growing seasons, and ensuring higher-quality produce. Additionally, plastic greenhouse covers can conserve water by reducing evaporation and provide insulation during colder seasons, allowing farmers to grow crops in regions with harsh climates.

- Q:What are the benefits of using plastic insect traps for pest control?

- Plastic insect traps offer several benefits for pest control. Firstly, they are cost-effective and easy to set up, requiring no additional tools or expertise. Secondly, they are environmentally friendly as they do not involve the use of harmful chemicals. Additionally, plastic traps are durable and long-lasting, providing effective and continuous pest control. They are also versatile, suitable for both indoor and outdoor use. Lastly, plastic traps allow for easy monitoring and disposal of trapped insects, making them a convenient option for pest management.

- Q:Can nursery trays be used for bamboo propagation?

- Yes, nursery trays can be used for bamboo propagation. Bamboo can be propagated through division or cuttings, and nursery trays provide a suitable environment for rooting and growing bamboo plants. The trays allow for proper drainage and can accommodate multiple bamboo cuttings or divisions, making them an effective tool for bamboo propagation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Greenhouse Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords