Graphite Electrode for Steel Making

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Graphite Electrode for Steel Making:

Raw material: Graphite Electrode raw materials use low sulphur and low ash CPC, coke plant pitch, HP grade graphite electrode add 30% Japan needle coke, UHP grade graphite electrode use 100% Japan needle coke. They are Widely used in LF, EAF for steel making industry, Non-ferrous industry, silicon and phosphorus industry.

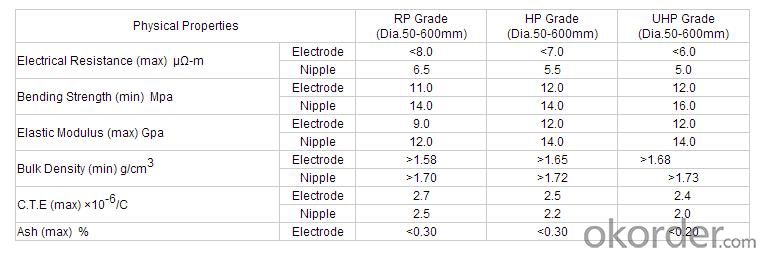

2.Specifications of Graphite Electrode for Steel Making:

1).Diameter:40 - 600mm or1.6"-24"

2).Length: 250 - 2400mm or10"-96"

3).Grades:RP, RPI, HP, SHP, UHP

Nipples:3-4TPI

Graphite electrodes size: dia75mm- 400mm

Our main products: all grades of graphite electrodes, such as RP, Impregnated and HP grade(over 6000MT); Anti-oxidation graphite electrodes, Male-female graphite electrodes. Also supply graphite rods, baked rods etc.

3.Applications of Graphite Electrode for Steel Making:

Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

4.Programmable Properties of Graphite Electrode for Steel Making:

1.Good electrical conductivity

2.High resistance to thermal shock

3.High mechanical strength

Grades:RP, RPI, HP, SHP, UHP

All graphite electrodes are offered with tapered nipples, i.e. 3 or 4 threads per inch, and meet the internationally accepted tolerances as per NEMA CG 1/ IEC 60239 / JIS R7201 standards.

5.Technical Data of Graphite Electrode for Steel Making:

- Q:How is it done? Cuttings? Tissue culture? I‘ve managed to keep quite a few alive and i‘d like to start making more. There must be a way to clone them because they have cultivars. ‘Thanks!!

- This is the easiest method of rooting African Violets Supplies you will need: styrofoam cup plastic cup, big enough to hold the styrofoam cup 1/4 cup vermiculite 1/4 cup perlite distilled water You will need a styrofoam cup to start. Punch holes around the cup about 1 1/2 from the bottom, and punch 4 or 5 holes right around the bottom edge. The bottom holes are for watering, the top holes are for drainage. Pour the vermiculite into the styrofoam cup. Top with the perlite. Cut healthy leaves from a violet plant. Stick the stems into the perlite, with or without rooting hormone. Pour a little distilled water into the plastic cup and set the styrofoam cup in the water. As water is absorbed by the vermiculite and perlite, the leaf cutting will be drawn down into the vermiculite. Set the cups on a window sill where it gets filtered light but no direct sun. Just keep it watered, but not soggy. In 3 or 4 weeks, you will see new little leaves emerging on top of the perlite. When the root system is well grown, pot them up in a peat based mix, and put them where they get good light, but not direct sun.

- Q:For a stem cutting of pothos is it best to put the cutting in vermiculite or potting soil and why. Also should you use rooting hormone and why.

- pothos are easy, if its for commercial output use the hormone, I would just use the potting soil, maybe eliminate a step in pruduction

- Q:I'm square foot gardening, and I need vermiculite. I went to the Home Depot to get some, but the man I spoke with told me that they didn't carry it, but NuraLime was basically the same thing. But before I add this to my $100 worth of soil, can they be interchangable?

- DO NOT MIST THE EGGS DIRECTLY it will cause them to go bad i had the misfortune of not knowing this about 10 years ago and mine all died.

- Q:How much cement does the vermiculite heat preservation layer need?

- Vermiculite is a kind of hydrate, which is blocky, flaky and granular. It is the product of weathering and alteration of natural mineral such as biotite. The interlayer water molecule is ignited at high temperature, and the volume is increased by 18-25 times. Rich in nitrogen, phosphorus, potassium, aluminum, iron, magnesium, silicate and other ingredients. Vermiculite has higher layer charge number, so it has higher cation exchange capacity and stronger cation exchange adsorption capacity. Characteristics: light weight, and good adsorption properties, not decay, can be used for 3-5 years (unlike the humus, coconut shell, clothing and other perishable)

- Q:I really need help w/ my science fair,and I would really appreaciate if anyone can help.Thnx.

- Home Depot I know for sure has larger bags. And I do believe that Lowe's carries it ,as well. Check there before you go paying a fortune to have it shipped. Good Luck!

- Q:I can't get hold of Peat moss, but have found Perlite and wondering if mixing them would be the same, or am i better off just using Vermiculite on its own to sow seeds? It's for a science project and I will be adding differing concentrations of fertiliser to each pot and measuring results

- Call your VET, NOW. You are dealing with a medical emergency, and this horse could die if he doesn't get some immediate help. This kind of fertilizer is poisonous to horses.

- Q:i am trying to put new insulation to my house

- see more information on this site

- Q:There is vermiculite in the soil. Can you eat the vegetables grown?

- There is vermiculite in the soil, and the vegetables can be eaten. Vermiculite is a natural, inorganic, non-toxic mineral that expands at high temperatures.

- Q:i am doing a project where you use a plastic container and put insulation in it to keep a fake bug frozen in a ice cube from melting. It will lie under a lamp that is on. What are very good insulators that wont let the heat come in and wont let the cold get out?

- Regular potting soil mixed with sand or just damp sand is fine. Her instinct is to bury the eggs and the sand or sand/soil mix will hold the shape better for that then the vermiculite. Vermiculite is better for incubating eggs.

- Q:Potting Soil, Vermiculite, Peat Moss, Coconut husk, etc what should the depth be?

- you put it in a jar that you then sterilize in a pressure cooker.. you then put the spores in that and wait for fungus to grow, some will get moldy, though those

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Graphite Electrode for Steel Making

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords